Household Appliance Engineering Report: Standing Fan

Household appliances Engineering report

Making of stand fan.

Due date:24/03/2017

The introduction

This report explores and examines the history and evolution of the stand fan detailing how they work and the materials used. The purpose of the report is to illustrate the functions and special features as well as to provide information about the social, environmental, sustainability and cultural connection that rose due to development and use of the stand fan. As the time progressed, technologies have drastically changed, the use of polymers and smaller sized powerful motors have allowed the stand fan to be lighter as well as improved performance and lowered the manufacturing cost when compared to heavy metals and bigger motors used in the past. a stand fan is a common household appliance used for cooling an area it is basically a traditional fan set on an adjustable pole which is attached to a base, it also contains at least 3 wind speed range.

The earliest model of fans appeared during the 1800’s it was basically a bipolar motor attached to a six-leaf shaped flat brass blades. These early fans were either a unique, or an expensive appliance, used in large offices or wealthy homes. The decade of 1910-1920 brought major changes. Around 1910, electric fans were being made for residential use, they had six wings and ran on slower speed and the cages were now made with steel due to lack of brass as well as the blades were rounded in shape and shrank from diameter of 8” down to 5”.

Description

A stand fan is a common household appliance they are much more effective and popular than other table fans as it can be adjusted to move up and down as well as its head oscillates till 180 degree or remain steady pointing at one direction. A stand fan is just like a normal table fan but its set on an extendable pole which is attached to a base. It has three speed settings and an on off button usually named as “0”. This type of fans is usually placed at a corner of the room or in an advantageous location to achieve greater cooling experience.

2.1 How it works

Stand/pedestal fan works with the help of an electric motor. A motor consists of coil of wire wrapped around a metal center and when electricity is passed through this, it produces rotational motion and a hub/cap connects the motor with the metallic/plastic blade which circulates the air around, these blades are shaped on an angle which helps to carry air from one point to another. The control box contains four switches three to control speed and one to turn the fan on or off. The extendable pole can be used to increase or decrease the height of the fan.

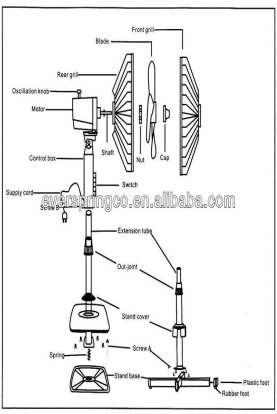

2.2 Assembly

- Slide the 2-off base cross sections together.

- Remove the screws from the center of the base cross section, and then fasten the fan pillar in position.

- Now unscrew and remove the plastic retainer that locks the two support sections together slide over and fit the plastic base cover.

- Set the height of the extension pole and then lock into position with the plastic screwed retainer.

- Set the motor and switch control section over the extension pole and secure into position with the locking screw.

- Remove shaft protecting cover and unscrew guard retaining nut/hub/cap anti-clockwise and remove.

- Take the rear-guard section and slide it over the threaded screw on the fan body (make sure, the handle on the guard is facing upwards).

- Screw on the plastic nut/hub/cap to secure the rear guard in place.

- Push the blade on to the motor shaft until it reaches the stop.

- Screw on the blade retaining cap/hub/nut in a clockwise direction to secure the blade in position.

- Hook the front guard on to the rear-guard section at the top.

- Secure the two guard sections together with the clips around the edges. The screw and nut at the bottom of the grille MUST be fitted.

Components

- Guard (rear and front grill) – it is a metal netting used to protect fan blades from any physical contact this protects the fan from any damage as well as the user.

- Motor – it is the heart of the fan as it converts the applied electrical energy into mechanical output energy.

- Blade – these are the paddle shaped objects connected to the motor which spins and creates airflow

- Hub/cap – it is a device which connects the fan blade with the motor.

- Extension pole – this is the component that makes stand fan special, it allows the user to adjust the height of the fan according to their preference.

- Head support frame – this component gives the stand fan its feature of tilting its head up or down.

- Switch box/ control box – this is the component which contains the electric circuit and switches which controls the speed of the fan as well as turn it on or off.

|

Component |

Material made from |

|

blades |

Polymer/aluminum |

|

Rear and back grill |

steel |

|

Extendable pole |

Polypropylene polymer/ metal |

|

Screws |

Metal (carbon steel/stainless steel) and plastic |

3.1 Materials

|

materials |

component |

Why it is used? |

|

Polymer/plastic |

-blades -Screws -Hub/nut/cap -switch |

-it is used because plastic would be more safer and cheaper than metals as well as it will decrease the weight of the fan. |

|

Metal (carbon steel/stainless steel) |

-extension pole -screw -guard (front and back grill) |

-it is used to make the product more durable |

Advantages and disadvantages

4.1 Advantage

- They are very easy to assemble also put them away when you are not using it as you can separate the components easily.

- You can move them around the house easily and put them in an advantageous location.

- Due to its extendable pole, you can adjust its height according to your preference.

- It is cheap and you can assemble it yourself.

- They’re lightweight and can provide cool air over large area.

- They can be easily cleaned.

4.2 disadvantage

- They’ve less safety for children as they might stick their finger inside the grill.

- Cooling range is smaller.

- there’s too much noise when the fan runs in higher speed.

Impact on society

This household appliance had a great impact on the society and people’s life. As before the invention of pedestal/stand fan there was only mechanical fans which required people to apply energy physically to cool the temperature or circulate air. When pedestal/stand, fan was invented it made peoples life way easier. During the early stage of the invention these fans were only used in big offices or wealthy homes but when refrigerated air was used in commercial buildings the fan makers focused more towards residential use. Then these types of fans started to appear at everyone’s home. The invention of pedestal/stand fan made life of the people more easier as they were cheaper and easy to assemble as well as it didn’t need much maintainance.

Conclusion

The making of the stand fan and different materials used in the stand fan has been explored in this report. Pedestal/stand fan is usually made of polymers and metals like stainless steel, aluminum. They are more advantageous than other table or ceiling fans due to its extendable pole which allows the user to increase and decrease its height according to their preference and also because its cheaper than ceiling fans as well as it is easy to assemble.