Amazon’s distribution strategy – case study and assessment

|

Amazon.com’s Distribution Strategy(Europe) – Review/Case Analysis |

Introduction

While taking a decision on the design of supply chain, companies should focus on its strategy, decision on operations and most importantly, proper planning. In a company, based on the needs of the customer and design of the systems, flow of supply chain management varies. While designing, reviewing constantly at different stages also helps companies differentiate various processes in their supply chain.

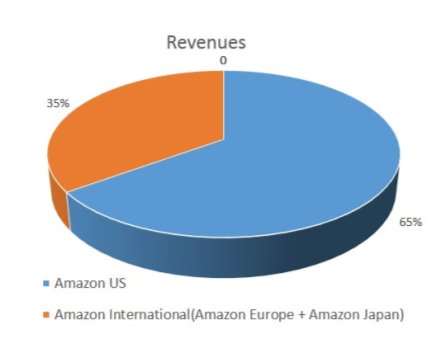

Amazon.com is an e-commerce company with its presence worldwide and headquartered in Seattle, United States. Amazon.com, in its early days dealt only with Books but later on it diversified into a lot of other product lines like Video Games, Electronics, Toys, Jewellery, Furniture, MP#s, DVDs among other products. Today they are a huge $75 billion organization with a very diverse product portfolio and successful operations round the globe. The new Kindle Fire Tablet computer is one of their latest notable product and their Cloud Computing business is one of the industry leaders. Going by the revenue, growth and market capitalization, Amazon is the 4th most successful start-up of all times.

Jeff Bezos started this amazing company in 1994 with the intention of “Get Big Fast”. This strategy was a brilliant one for the company in US as they were able to function with a competitive lead time for delivery after the orders were placed. Now this strategy was also put in place for the expansion in Europe. Not only were the European markets culturally different from US but also the market conditions and the consumer behaviour & expectations different from a consumer in US. The challenges here were very dissimilar to the operational challenges in US in terms of transportation, stocking and distribution.

The report will look into the challenges that Amazon faced in Europe and the operational/supply chain decisions they had make to overcome those challenges, also, “How has globalization made strategic fit even more important to company’s success”. The recommendations/ analysis are based on the concept of centralization of the distribution across a full continent and the concepts taught in the class.

The report will look into the challenges that Amazon faced in Europe and the operational/supply chain decisions they had make to overcome those challenges, also, “How has globalization made strategic fit even more important to company’s success”. The recommendations/ analysis are based on the concept of centralization of the distribution across a full continent and the concepts taught in the class.

AMAZON US

“Earth’s Biggest Bookstore”

Amazon used the Internet to change the business of buying books into a very fast, easy and enjoyable shopping experience. Amazon has more than 2.5 million different book titles in its kitty and is very rightly called the “Earth’s Biggest Bookstore”.

From the very beginning, Amazon always kept the wholesalers and the publishers on their side which thereby allowed them to keep a very truncated inventory and low inventory holding costs. These tie-ups with wholesalers and publishing houses not only allowed Amazon to reduce costs on warehousing but also get huge bulk discounts, for example From a publishing house Amazon used to get a discount of approximately 48% and around 41% from the wholesalers)

Amazon had a general lead time for delivery of 4 to 7 business days across the whole country of United States. Amazon developed its infrastructure hugely in the late 90’s and eventually launched their Music and Video businesses also. The idea was to “Get Big Fast” through diversification and geographic expansion by having more distribution centres in their business geography.

Some would say that the expansion of Amazon was the fastest expansion experienced by any company for its distribution capacity. Expanding and making distribution was the first step, next step was to figure out which distribution centre will carry which all products, given the fact that Amazon not only expanded in distribution capacity across geographies but also in terms of the product lines in its product portfolio.

Some would say that the expansion of Amazon was the fastest expansion experienced by any company for its distribution capacity. Expanding and making distribution was the first step, next step was to figure out which distribution centre will carry which all products, given the fact that Amazon not only expanded in distribution capacity across geographies but also in terms of the product lines in its product portfolio.

The 3 aspects of deciding the products to be carried by a distribution centre are:

Amazon employed a lot of systems to enhance their operation efficiency. The ones which were the most impressive and successful are:

- Pick-To-Light System

- Radio Frequency Technology

- Voice Technology

- Pick Profiles

- Amazon Standard Identifying Number (ASIN)

- Performance measuring key metrics

As Jeff Wilke, the Vice President of Operations at Amazon said about what Amazon had,

Amazon quickly adapted to the Six Sigma DMAIC reviews as a tool to reduce variations and defects in its distribution centres.

Jeff Wilke’s team followed 5 strategies to improve inventory management

- Better forecasting of customer demand by improving the ability of the software by refining it to the tune of better anticipation of the demands, both seasonal and regional. This made sure that risk of buying either too much or too less was reduced.

- Better relations with the wholesalers and direct vendors to cater to any sudden surge in demand for any particular bestselling book title. This was also used to get some needed momentum for the slow velocity titles.

- Available-to-Promise Functionality: Amazon integrated the supply chain management systems of its suppliers with its own thereby getting a synergy in the process. Now amazon was able to tell its customers the exact time frame in which it could deliver the products to them. For example, if a product is available with the Amazon distribution centre themselves, then the lead time for the delivery of the product was within 24 hours. But if the product was not available with the Amazon DC then the lead time for delivery increased to 2 – 3 business days. This allowed Amazon to have the information about the inventory of the suppliers at all times at the very item level.

- Cascading Buying Rules: These rules by Amazon determined which supplier was the best fit for which product in terms of the price and the options for delivery such that if the item is not available with the supplier giving the best price then the next supplier in cascade will be selected for the delivery.

- Drop Ship Orders: Amazon took some time to adopt this strategy which they should have adopted in the very beginning. According to Drop Ship strategy, whenever the customer orders an item and the distribution centre of Amazon does not have the product then Amazon places the order on its supplier. Then instead of the supplier shipping the item to Amazon DC and then the Amazon DC shipping the item to the customer, the supplier directly ships the item to the customer, thereby drastically decreasing the lead time for delivery by removing the unnecessary steps of the supply chain products.

In addition to the above mentioned processes and strategies, Amazon also used method called “Postal Injection” or “Zone Skipping”. In this method, the fully loaded truck from the distribution centre directly goes to the major cities, easily bypassing the postal service’s sorting hubs where the delivery packets are sorted according to the respective cities and states.

AMAZON EUROPE

The initial targets for Amazon were UK and Germany, primarily because both these countries were the prime markets for book selling and online purchasing in the continent of Europe. Germany had an excess of 2000 publishing houses and UK had an excess of 3000 publishing houses. Amazon made an acquisition in Europe by acquiring Bookpages and TeleBuch in UK and Germany respectively.

Again, in line with the idea followed in US, Amazon Europe wanted to “Get Big Fast”. Both the UK Amazon.co.uk and German Amazon.de increased their product portfolios by integrating the music and video businesses along with the books business at the very offset of the culmination of the respective expansions in the two countries. Even though the competition from the online bookstores of the respective countries was fierce, Amazon was successful in becoming the market leader in both the countries. The combined sales of the 2 countries crossed the 10% of the total Amazon revenue mark, signifying the epic success of the geographic expansion.

The next venture was in France. When Amazon entered UK and Germany they did it through acquisitions, however when they entered France they did not acquire any established company, instead they got the business up and running from the scratch. The formula was simple here too, “Get Big Fast”, which is why the business started with the complete portfolio of books, music, video, toys, et al.

Growth in International sales for Amazon grew by 74%, which in turn helped the European business to cross the 13.4% of the total Amazon revenue mark.

Challenges in replicating amazon’s US model in EUROPE

Although Amazon was doing well in Europe but the ambition was high as they had the intention to repeat the success of Amazon US in Europe too. However they were confronted with some heavy challenges from the European markets. These challenges could be tackled but to do that they required some radical change in the strategies that Amazon applied and adopted in US.

The 4 main challenges were:

- Selling regulations in Germany & France

The prices of the books being sold in Germany & France were fixed. No discounts could be offered on those prices. The selling model for Amazon in US was to offer discounts on the prices of the books, which they got from the wholesalers and publishing houses. Over here they could not provide those discounts that they got on the bulk purchases from the wholesalers and publishing houses.

- Payment options

In Europe, more than 62% of the customers used cheques to make the purchases. The core competency of Amazon was online retail which meant online purchasing via credit cards. This came as a major challenge to Amazon as they did not have any brick or mortar store where the concept of payment through cheques can happen.

- Different supply market factors

In US, Amazon relied heavily on the suppliers for the books. However in Europe they suffered a setback because of the dearth of wholesalers and big suppliers. In UK although they were able to manage the supply with a handful of suppliers, but in France there were none. This forced Amazon to have tie ups with umpteen number of publishers for the supply of books.

- Low penetration of EDI in European countries

Amazon used EDI (Electronic Data Interchange) to have a communication with the supply chain management of the suppliers in US. This increased the efficiency of their own supply chain tremendously. In case a supplier was having a stock out of a particular item in his inventory, he could respond back in real time to Amazon with a rejection to take the order from customer. This enabled Amazon to immediately send the information back to the customer about the unavailability of the item. This, however, was not much in use in Europe as they still used the concept of emailing and Fax but not any sort of real time data sharing.

In addition to the challenges mentioned above there were other challenges too. Amazon relied comprehensively on the national postal services in the respective countries of Europe where they were operating. But they were competitive only in their own countries and not in other countries. This created a challenge for Amazon because they had a lot of shipments which were cross country shipments.

Problems Identified & Recommendations

With the challenges in mind there were a certain number of options for Amazon, which could solve these challenges for Amazon as they go forward and expand more and more into the European market. These recommendations require radical change in the strategy from the one which was followed in United States.

Should Amazon Europe build an EDN?

Europe as whole is treated as a single entity by amazon. Although they have separate units for separate countries, the parent company, Amazon, thinks of it as a single market. Therefore they intend to have a EDN (European Distribution Network). As per this concept, the entire Europe will have a single distribution network not separate distribution networks of individual countries. This is a massive step because Europe as a market is huge in size and very fragmented. But we suggest that a single EDN will be much more beneficial and the reason for that are mentioned in the bullet points below:

- Operating independent units is much more expensive than a single unit

- EDN implementation ensures uniform product offerings in each country which in turn will help in the consolidation of the business across the entire continent

- EDN implementation ensures procurement department centralizes purchases, and avails higher volume discounts as this is the prime strategy on which Amazon grows and thrives

- In case of system failures, EDN implementation reduces risk of relying on single DCs, making sure that the plan B for every failure is in place

Hence implementation of EDN is a logical choice.

Should Amazon use a single centralized DC or keep the existing 3 DCs and let them share orders?

Another major problem for Amazon is to figure out whether or not to have multiple individual DCs or have just a single unified Distribution Centre at a strategic location. This problem is in line with the strategy for the implementation of EDN in Europe.

We suggest that they should integrate Amazon’s European operations as a whole and accept it as a single market. With that in mind they should follow the following steps to achieve this target,

How to sustain customer satisfaction after implementation of EDN?

A major drawback for EDN is that this will cause a serious impact on the customer satisfaction levels. This is primarily because the customers who are used to getting their items delivered free of cost in very less time due to the distribution centre being in that country itself will have to either pay to get the item delivered in less time or get the item delivered in a longer time. All in all the lead time for delivery will increase and only additional cost for the customer can decrease that.

To improve customer service Amazon must follow the following steps,

Should the French Distribution Centre be left operational?

This problem is a slightly tricky one as this requires Amazon to decide on whether or not to cut off an important limb from their body. Since the operational usage of French Distribution Centre will be redundant, is it viable to keep it running or remove it from the unified distribution network of Europe?

This question can have multiple answers and no answer is possibly entirely correct. However we suggest that Amazon should not immediately close the French DC but gradually phase it out of the distribution network.

During the expansion phase of Amazon into the rest of the Europe this DC can act as a support for the newer countries where Amazon wishes to venture in the European Distribution Network.

Immediate disposition of this DC is not a viable option as this will cause a lot of complexities for the entire EDN. Since this DC will have some competencies and must be having some items which are solely kept in the inventory at this DC itself, this Dc will serve its purpose for some more time.

The best option is to decommission the French DC in a phased manner over a period of time.

How to detect demand trends, especially for fast moving items, if European level buying is consolidated?

The only way to make sure that the inventory levels in a distribution centre is at an optimum level is through better forecasting. Making sure that the replenishment in a warehouse is done at proper interval in adequate quantities is by having an accurate information about the demand in future.

Demand estimation is the backbone for any supply chain management system. Proper implementation and information processing through ERP is the method used by the most successful companies in the world. ERP helps improve the planning for the supply chain, both inbound and outbound aspect of it.

Besides that money saved through the cost cutting initiatives should be invested to develop the supply chain, logistics and distribution characteristics of the EDN.

In addition to that, it is very important to capture the easy wins first and get a hold of the market. It is very critical for Amazon to have standardization and build synergies across the divisions in Europe. To do that it is important that Amazon defines and implements comparable metrics (for example vendor lead time) across the European countries to develop enhanced understandings of their operational activities

References

Childerhouse, P, & Towill, D 2011, ‘Arcs of supply chain integration’, International Journal Of Production Research, 49, 24, pp. 7441-7468

Forbes.com 2011. Why Amazon Is The Best Strategic Player In Tech. Retrieved February 27, 2014 from http://www.forbes.com/sites/venkateshrao/2011/12/14/the-amazon-playbook/2/

Joseph Bonney 2012. Amazon’s Supply Chain: Delivering Clicks and Bricks. Journal of Commerce. Retrieved February 28, 2014 from https://www.joc.com/economy-watch/amazons-supply-chain-delivering-clicks-and-bricks_20120130.html?qt-webcasts_podcasts_whitepapers=0

Knowledge @ Wharton 2009, November. Fit for the Holidays: Amazon Is Shaping Up and Shipping Out. Retrieved February 27, 2014 from http://knowledge.wharton.upenn.edu/article/fit-for-the-holidays-amazon-is-shaping-up-and-shipping-out/

Lichocik, G, & Sadowski, A 2013, ‘EFFICIENCY OF SUPPLY CHAIN MANAGEMENT. STRATEGIC AND OPERATIONAL APPROACH’, Logforum, 9, 2, pp. 119-125

Mark Brohan. InternetRetailer.com 2010. Amazon’s secret European weapon: Square footage. Retrieved February 28, 2014 from http://www.internetretailer.com/2010/08/31/amazons-secret-european-weapon-square-footage

Modern Materials Handling 2012, December 14. Supply chain: Amazon is changing the rules of the game. Retrieved February 27, 2014 from http://www.mmh.com/article/supply_chain_amazon_is_changing_the_rules_of_the_game

MWPL. Amazon Global Fulfilment Center Network. Retrieved February 28, 2014 from http://www.mwpvl.com/html/amazon_com.html

Roh, J, Hong, P, & Min, H 2014, ‘Implementation of a responsive supply chain strategy in global complexity: The case of manufacturing firms’, International Journal Of Production Economics, 147, Part B, pp. 198-210

Viswanadham, N, & Samvedi, A 2013, ‘Supplier selection based on supply chain ecosystem, performance and risk criteria’, International Journal Of Production Research, 51, 21, pp. 6484-6498

Order Now