Bio-Minicry: Next Phase of Sustainable Imitating Technology

BIO-MIMICRY: THE NEXT PHASE OF MODERN SUSTAINABLE IMITATING TECHNOLOGY

- Abstract:

Bio mimicry is a form of learning and then reproduce nature’s forms, processes, and ecosystems to create more sustainable designs. Bio mimicry has stepped into the Advanced technologies section when it comes to thinking out of the box strategies; which mainly relate to adapt the behaviour and environmental characteristics of nature or the living species including mammals, reptiles, flaura and fauna. This review article submits the overview of the technology of the world around us by adapting the blueprints from nature, and applying those ideas to improve the co-existed ones. The Review tries to emphasise on the various economical and ecological aspects of the current Bio mimic technology in various fields scaling down their Growth and Cons in Production, Evaluative thinking and Green Technology.

- Introduction:

Bio-mimicry – mimicking Nature’s designs to overcome the manmade designed challenges which can be applied to a varied range of obstacles all the way from drafting a CAD model to several systems, services and the environmental aspects of the product development.

Bio-Mimicry has been along from a long time since the 1900’s when the revival of the pollen grains of the plant cocklebur got stuck to his coat which empowered Swiss engineer Georges de Mestral to invent a new type of fastener which later became famous and patented as Velcro Industries. This incident embarked a new process and methodology of thinking for new discoveries and inventions.

The Method to imitate the behaviour the organisms or the horticulture is mainly according to the type of imitation shelled down for a particular application which is mainly divided into:

(1) Bio – inspiration (2) Bio – replication (3) Bio – imitation.

The other area of concern for today’s technological ladder is to produce eco – friendly and much more Green designs and products which can adhere to the current eco system regarding the concept of “Form follows Function “. Bio – mimicry can be stated as the example of a Helicopter being as similar as a bumble bee but the mechanism of hovering are totally different, which states that only a part of the idea or concept has been adapted to make something to travel at very high grade speeds.

The Lotus plant has the ability to repel the water droplets on its surface which created avenue for a new technological impact for the surface coats and paint industries enabling them to make paints which could swipe off the dirt from the surface without any external cleaning agents. Medical field has also advanced from the nature’s geometry in such a manner that it can now adapt the soul DNA structures of various Microorganisms to tackle the cancer agents along with widely induced drug delivery system and Organs on chips concept which is indeed revolutionary.

The manufacturing scale and the designs are also mimicked from the nature: the sustainability concept along with the proficient use to the application, such as surface coat for anti – corrosive metals and several solar cells also use the mimicked concept of bug eyes being anti-reflective and adapting the UV rays band spectrum at a much higher scale than the normal solar cells imparting higher efficiencies to the solar cell output. The main agenda is to invent production, operations, and methodologies that are well-adhered to a sustainable Green Living.

The core idea is that nature has already solved many of the problems we are grappling with. Animals, plants, and microbes are the consummate engineers. After billions of years of research and development, failures are fossils, and what surrounds us is the secret to survival.

- Why bio mimicry is the new face of advancement in 21st century science?

Today’s world is facing the hurdles of overcoming the defects from their products and trying to maintain them for a longer run for much better output both economic and ecological aspects. The constant graph of growth for the awareness of bio mimicry embarks the start of a phase, all the way from the industrial model to an ecological one. Experts suggest that the industrial revolution period may have admired us with some of the many vital innovations, but it was on the base of ecological depletion and non – sustainable production technology.

The following review paper will cover all the fields that have been developing their scaled growth over the past decade gradually sparking the innovations and replicating natures system and its operations in their respective field for much better output that they’d usually get without using them.

The recent developments in nanotechnology and manufacturing are helping us to manipulate and innovate products more like Nature does – from the bottom up method, but there is still much of the gap to fill such as producing materials at ambient temperatures and still have desired properties, such as strength without wasting any energy.

The recent developments in nanotechnology and manufacturing are helping us to manipulate and innovate products more like Nature does – from the bottom up method, but there is still much of the gap to fill such as producing materials at ambient temperatures and still have desired properties, such as strength without wasting any energy.

The Flowchart resembles the fact that a method or a process has been adapted now by the recent innovators and Big MNSCS regarding the fact to make or produce something new everytime in the research and development section.

The industries are much more imparting importance to their R&D department today because of the constant demand for better products with high grade efficiencies and higher production rates. They also have the criteria to waste minimal of the raw products used in the production which is inevitable at the present scale technology. Bio mimicry steps in there with the concept of giving out the agenda’s for production areas to work and emphasise about making and designing Green products which would be suitable to the environment as well as the application by adapting different concepts and ideas from nature. The Eco Friendly method is generally based on three factors Economic, Environmental and Social Aspects. The Main goal is to achieve the complete interaction and balance co relating in all these three factors.Adding to that the production and the blueprints of a company always have the environmental indicators which are Carbon Footprint, Energy Consumption, Air acidification and Water Eutrophication.

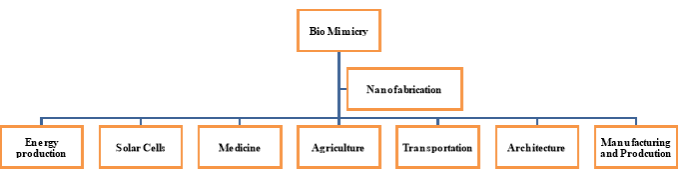

Nanofabrication has a greater role to play in the field of bio mimicry because of the sole reason to scale grade and study the roots formation of a structure and mimicking it to a real scale model application.

Example: Studying the gecko feet structure from the DNA scale level to understand the physics and the arrangement of the surface involved in high quality of friction imparting that theme to that of the tyres i.e. real scale model application.

The Following subtopics of this review covers various applications where the symphony of nanofabrication and bio mimicry is synched to produce application of high intellectual usage for the industry as well as day to day science ; their approach, their limitations, advantages and problems that they have to tackle have been reviewed and discussed thoroughly.

-

The Classification of Bio Mimicry Applications flowchart:

The Classification of Bio Mimicry Applications flowchart:

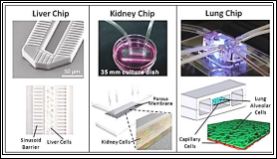

- Medicine:Nanofabrication technology has enabled the scientists and researchers all over the globe to widen their horizon to an extent where they can create cell structures that go beyond the current three dimensional in vitro models by giving them a new formed tissue – tissue interfaces, spatiotemporal chemicals and dynamic mechanisms and behaviour of the micro organisms.

In One research the living cells are structured within the microfluidic aids that have been designed to withstand and keep the tissues intact in the same manner as they are placed in the microorganisms. Adding to that also the organ to organ behaviour is observed and analysed so as to know the interaction between a kidney tissue and a liver tissue with their co relation to the brain cells. This study requires pathophsyciology which can be helped to understand how Organs on chip can behave when they are tested in field. PDMS a microdevice containing poly-dimethylsiloxane are molded inversely that mimics the complex structure of the relative tissue epithelial interface so as to know their behaviour in the body. Various body organs such as Lungs, kidney, liver, Breasts Chips have been formed and tested mainly on animals which proves to be quite costly and dreadful. Another application is to replicate the morphology of the chemotoxins from the cancer cells during their treatment to ease the process and the fight against the same known as ” sink cells ” which scavenge the chemokins. The embarkment of mimicking the mosquiotoes venom for anti – malaria and other pathogen agents also have been formulated to avenge those diseases.

- Sustainable manufacturing: The manufacturing industry has started adapting the systematic approach for the biomimicry method in their various processes in a very serious and efficient attempted manner for more eco friendly product designs. The products are designed with keeping in mind the EES ( economic, environment and social ) which often led to reflect each other ; bio mimicry helps to balance these three factors and asses different products at a very early stage.The study of morphology of various surfaces leading to the slection of materials is mimicked from that of the relavant application. Example: The surface of Tio2 is sprayed with PEEDOS:PSS for the production of Solar cells which was adopted from Plants. The Process of Photosynthesis.The main agenda for this field is to take the help of Compter Aided Engineering and the Data to give sustainable and function efficient products at a very large scale at minimal cost of production.

- Architecture: The basic concept of architecture came from mimicking the trees withstanding extreme climate and different microorganisms including the ant mounds ; the spiders web. We generally think of termites as destroying buildings, not helping design them. The modern buildings have an internal climate control system originally inspired by the termite mounds. The operation of buildings represents 40% of all the energy used manually so more energy efficient concepts have to be introduced. The Honey comb structure morphology has been motivated for the selection of building materials which can withstand high pressure winds and climate conditions. The tensile strength of spiders larva directs to the materials of large scale structures requiring greater tension forces.

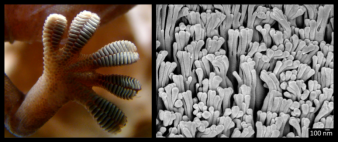

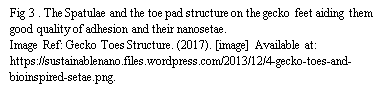

Gecko (Adhesion applications ): Geckos have the amazing gift the adhere and repel their feet and toes on the surface making them stick to the surface to and fro quickly.It is possible for them to perform such a task because of millions of nano-scale hairs present on their toes known as setae and spatulae. This creates friction between the toe and the surface area on which the toe is adhered to and as the surface area increases the frictional force on the toa and the surface also increases. We can note the presence of Vander Wals forces in between the toe and the surface, Vanderwalls Forces are fragile attractive forces usually present between nearly all chemicals and materials. The frictional force requires the application of pressure for adhesion and load removal for the to and fro movement ; The Nanotechnology steps into the operation where various topographical and morphological scaling techniques are graded and used to itch down the patterns down to the nanoscale and make them implement on the industrial scale products.

The ability that the gecko adapts to create such high amount of adhesion reasons to the hierarchical and fibrillar structure on its feet. The High surface area usage of the spatula at each step enables gecko to increase the toe-pad surface area and features to use them in a combinationWith the aid of the multitiered porous anodic alumina template and capillary force bridged nanoimprinting, we can successfully plant a gecko imprint toe pad formation of nanopillars.Improvisation has also been done to increase the adhesitivity of the application to upto 150%. As the surface area gradually decreased the adhesive forces also emulated. The pillar topography also aided the fact of the increase in hydrophobicity, which proved to be quite fruitful in the applications of dry cleaning materials and super hydrophobic applications.

-

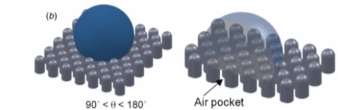

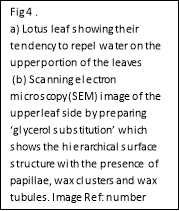

- Super-Hydrophobic Surfaces: The basic example of a naturally hydrophobic surface is the lotus leaf, the leaf’s when scaled down to a Nano size ; it is observed to have the surface with repels the water particles on its surface. This tendency allows the plant to withstand the dirt and self-cleaning mechanism. When the leaf is encountered with water, it creates thee superhydrophobic angle at around 160° which allows the water to roll down the leaf on the way helping to coolect all the dirt patricles on its surface. This is known as the lotus effect where the surface structure is at micrometer-scale bumps as well as nanometer-scale hairlike structures with a layer of wax on the leaves. The leaf air composite structure allows the air to trap beneath the water droplets and is the main reason for high contact angle and rolling behaviour of water droplet on the leaf. With the help of nanofabrication methods a superhydrophobic and transparent biomimetic surface can be fabricated by using the colloidal lithography and plasma etching combination. Plasma etching techniques are also advanced enough to built tall tower like strucutres on glass sheets and adding to that coating with fluoroalkylsilane self-assembled monolayers in the aim to obtain the chemical layers with a low surface energy, the contact angle of the nanostructured surface around 150° and 110° for water and hexadecane, respectively. In addition to the super hydrophobic abilities they also retained the quality of transparency which also adds on the property and creates a massive impact in the solar cell industry.

sd

- Solar Cells: The butterfly wing scales templating method is easy and economic design for the synthesis of hierarchically periodic microstructure titania photoanode without the need for complicated experimental conditions or equipments, such as photo lithography adopted.

The quasihoneycomb structure titania replica photoanode has a perfect light absorptivity and higher surface area, which give great advantages to the light harvesting efficiency and dye sorption. This structure gives the butterfly ultrablackness wings, so it is convincing that we could obtain potential ultra-absorptivity photoanode adopting the quasi-honeycomb structure. This method also gives us a better option for photothermal, photocatalyzed, and photosensitized devices research. This fabrication method have the chances for their application on other chitin substrate template and metal oxide systems that could turn out to be in the production of optical, magnetic. or electric devices or components as building blocks for nanoelectronic, magnetic, or photonic integrated systems The butterfly wing have a greater band of reflectance for the Uv rays because of the alternative layers of Air and chitin.

The honeycomb structure has the upper hand of refracting on trapping light similar to the fiberoptic cable. The relative high refractive index on the wings helps to entrap the solar rays much easily. That is, the light enters the material, but whenever it co inciceds with the rest of the surface it is mirrored back to that of the reflective part. This shows that no incident light is wasted everything is reflected back and used.

Nanotechnology plays its part in managing the topography and aiding the need to study the reflections and increasing optical path length than the wings.

Nanofabrication aids to the butterfly wing scales microstructure titania film photoanode and can improve the wing scales and light absorbitivity on a particular surface area of the DSC photoanode.

- References:

- Huh, D., Torisawa, Y., Hamilton, G., Kim, H. and Ingber, D. (2012). Microengineered physiological biomimicry: Organs-on-Chips. Lab on a Chip, 12(12), p.2156.

- Alexandridis, G., Tzetzis, D. and Kyratsis, P. (2016). Biomimicry in Product Design through Materials Selection and Computer Aided Engineering. IOP Conference Series: Materials Science and Engineering, 161, p.012046.

- Nesta.org.uk. (2017). Biomimicry | Nesta. [online] Available at: http://www.nesta.org.uk/event/biomimicry

- Wootton-Beard, P., Xing, Y., Durai Prabhakaran, R., Robson, P., Bosch, M., Thornton, J., Ormondroyd, G., Jones, P. and Donnison, I. (2016). Review: Improving the Impact of Plant Science on Urban Planning and Design. Buildings, 6(4), p.48.

- Arndt, D. (2017). Nature’s nanotechnology, bio-mimicry, and making the superpowers of your dreams a reality. [online] Sustainable Nano. Available at: http://sustainable-nano.com/2013/12/03/natures-nanotechnology-bio-mimicry-and-making-the-superpowers-of-your-dreams-a-reality-4/

- Hu, S. and Xia, Z. (2012). Rational Design and Nanofabrication of Gecko-Inspired Fibrillar Adhesives. Small, 8(16), pp.2464-2468.

- Aryal, M., Ko, D., Tumbleston, J., Gadisa, A., Samulski, E. and Lopez, R. (2012). Large area nanofabrication of butterfly wing’s three dimensional ultrastructures. Journal of Vacuum Science & Technology B, Nanotechnology and Microelectronics: Materials, Processing, Measurement, and Phenomena, 30(6), p.061802.

- Ho, A., Yeo, L., Lam, Y. and RodriÌguez, I. (2011). Fabrication and Analysis of Gecko-Inspired Hierarchical Polymer Nanosetae. ACS Nano, 5(3), pp.1897-1906.

- Lim, H., Jung, D., Noh, J., Choi, G. and Kim, W. (2009). Simple nanofabrication of a superhydrophobic and transparent biomimetic surface. Science Bulletin, 54(19), pp.3613-3616.

- Zhang, B., Park, J., Kim, K. and Yoon, H. (2012). Biologically inspired tunable hydrophilic/hydrophobic surfaces: a copper oxide self-assembly multitier approach. Bioinspiration & Biomimetics, 7(3), p.036011.

- Ensikat, H., Ditsche-Kuru, P., Neinhuis, C. and Barthlott, W. (2011). Superhydrophobicity in perfection: the outstanding properties of the lotus leaf. Beilstein Journal of Nanotechnology, 2, pp.152-161.

- Zhang, W., Zhang, D., Fan, T., Gu, J., Ding, J., Wang, H., Guo, Q. and Ogawa, H. (2009). Novel Photoanode Structure Templated from Butterfly Wing Scales. Chemistry of Materials, 21(1), pp.33-40.

- Sharklet.com. (2017). Technology Overview | Sharklet Technologies, Inc.. [online] Available at: http://sharklet.com/our-technology/technology-overview/