Brake Caliper: Part and Functionality

Caliper is inarguably the most crucial part of a braking system in any kind of Brake assembly, be it a traditional Drum Brake setup or the more modern Disc Brake assembly. The caliper acts as an interface between the driver’s action to stop a moving vehicle and the reaction of the vehicle’s wheel to this action. Hence, a caliper sees both- The action and the reaction.

The of using the are as follows: High corrosion resistance, Good machinability, Good flow characteristics, Lower density

The caliper in itself does not stop a moving wheel but it houses a set of brake shoes which press against the rotors of a wheel and stop them by creating friction. The pressing of the brake shoes takes place due to a hydraulic set-up consisting of pistons on the caliper which push the brake fluid which in turn pressurises the brake shoes.

As the primary purpose of the caliper is to transfer load onto the brake shoes and to load them, it is essential that the caliper be a rigid part. As a result, calipers have been following the usage of traditional load bearing materials like Cast Iron, Forged steel, etc. However as every rigid part in an automobile comes with an opportunity to save weight, some research is being carried out in order to reduce the weight of the caliper while retaining its characteristic to carry and transfer sufficient load.

Brake Caliper

Current Material:

In this direction of weight save, Aluminium is being employed in the devise and development of a brake caliper. By nature, aluminium has lower density (2.7 g/cm3) as compared to ductile Iron (7.8 g/cm3). This conversion to aluminium has saved weight upto 40 percent.

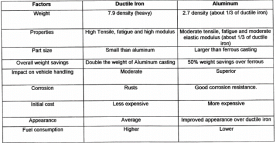

Comparison between Traditional Vs Current Material

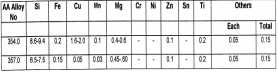

The design and performance criteria for the caliper castings are stiffness, dimensional rigidity and temperature and fatigue life. The aluminium alloys which are mainly considered for calipers are A354 and A357 alloys.The calipers in the brake system are currently made of Aluminium alloys consisting 7-10% Silicon, 0.15-0.2 % Ferrous, 0.05-2% Copper, 0.03-0.1% Manganese, 0.4-0.6% Magnesium, 0.1% Zinc, 0.2% Titanium.

Table: Composition of Aluminium Alloys (A354&A357)

Aluminium 354 has higher copper percentage when compared to Aluminium 357 hence so eutectic change. The rate of corrosion of the Aluminium 354 is higher as compared to Aluminium 357. Both the alloys undergo Boron Nitride Coating where A354 show higher elongation over A357.This means that choosing 357 over 354 is a better choice for our desired part: Brake Caliper.

Drawbacks of the Current Material:

One main drawback of using this material for automotive applications is its low Fatigue strength which is of extreme importance in a load bearing part like Caliper. This issue has to be addressed while selecting a new material.

Proposed material

Magnesium Alloy (AZ91)

Magnesium is one of the lightest materials with density 1.74g/cm3, compared to Aluminium and Ductile Iron. Magnesium is the most commonly used alloying element as sea water has 0.3% which is considered as the major source.

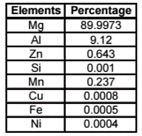

The major alloying materials used for the proposed material AZ91 are

8.5-9.5% Aluminium,0-45-1%, Zinc,0.05-0.1%,Silicon, upto 0.03% Copper,0.02%Nickel and 0.05%Ferrous.

Chemical Composition of Magnesium Alloy AZ91

Minimizing the weight of a caliper leads to the reduction of unsprung weight of the car therefore improving the fuel efficiency and heat dissipation. As the alloy is softer, it has high damping capacity and good impact resistance.

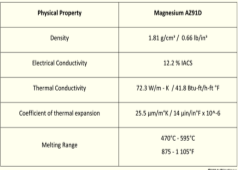

Physical Properties of AZ91

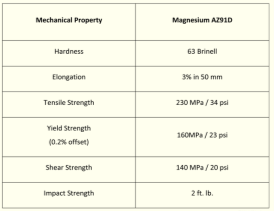

Mechanical Properties of AZ91

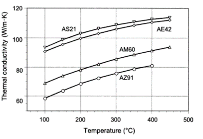

Fig.Thermal Conductivity

The thermal conductivity of AZ91 is comparatively low with the other Magnesium alloys which reduces overheating of the brake fluid decreasing the problems associated with it.

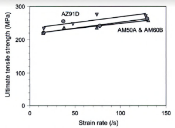

Fig. Ultimate Tensile Strength Vs Strain Rate

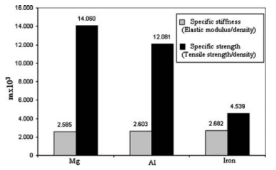

Comparison chart of Specific Stiffness and strength of the materials

The specific stiffness of Magnesium is considerably equal to that of Aluminium whereas the specific strength is higher in Magnesium. Due to the increase in strength, fatigue resistance increases due to high Magnesium content. Brake Caliper needs high Bending stiffness which is greater in AZ91 because of high elastic modulus. Low melting temperature of Magnesium leads to longer die life. Magnesium displays higher corrosion resistance than aluminium when it is coated with Phosphate-Permanganate and Zinc-Nickel alloys. Though the cost is more than the former, it can be used because of high bending stiffness as well as lighter mass which results in good functioning of the vehicle.

Magnesium Alloy (AZ91) is lower in density than Aluminium Alloy (AL3XX) thereby reducing the weight (33% lighter) and improving the efficiency of the vehicle. It displays high strength, modulus of elasticity, heat dissipation and castability when compared to AL3XX.

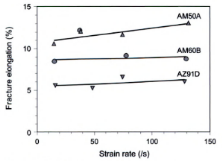

Magnesium alloys also exhibit better nature when exposed to physical loading like better damping capability and lesser elongation at failure loading.