Building High Performance Organisations

This report is about the food processing company- Absolute foods. The report examines the concept of lean thinking, principles and processes. It analyses the kinds of wastes and the implications and challenges for applying lean in Absolute foods. The recommendations are provided in relation to applying lean. The second part is about KFC that reflects on the five principles of lean and explains the benefits of implementing lean for the business performance of KFC.

This report is based on the Scotland based food processing company called “Absolute foods”. The purpose of the report is to create greater understanding of the lean concept in food processing company and to find out the implications while implementing lean in the global business environment. The report will cover the development of the lean philosophy, principles and processes, lean in food industry relating with Absolute foods, implications and challenges and recommendations to Absolute foods. On the second part of the report, the benefit of implementing lean on the fast food chain KFC business will be analysed. The source of information for this reports are journals, internet and books that are related with the concept of lean.

According to Hines et al (2004) the concept of lean is originated from the companies in Japan and particularly from the Toyota production system. The concept of lean has its origin after the World War II and the study has been mostly done in manufacturing companies. Womack et al (1990) in the book “machine that changed the world” mentioned that lean originated by combining the important aspects of craft and mass production. Lean thinking came in light after the publication of this book. Since the publication of this book many studies has been performed (Womack and Jones, 1996; Hines et al, 2004). Mass production started to result in the creation of many problems, which was not adding any benefits for the company and lean concept of lean started to emerge. Shah and Ward (2003) mentions that lean is multi-dimensional and includes many management practices, just in time, work teams, quality systems, supplier management and many more. Womack and Jones (1996) adds that lean thinking intents in reduction of human effort, inventory, the delivery time and delivers the product in high quality and economical way. Abdulmalek and Rajgopal (2007) augments that the main aim of lean approach is reducing cost by eliminating non-value added activities. Toyota Corporation has proved to be a success by implying the concept of lean. According to Abdulmalek and Rajgopal (2007) some of the main tools of lean are cellular manufacturing (developing the entire process for a product in a cell), JIT (Just in time- customer demands and pulling all the way down), Kanban (signalling for implementation of JIT), TQM (Total quality management- system of continuous improvement which assists participative management and values the customer needs) and 5S’s (Sort, Straighten, Shine, Standardise and sustain- for organising the workplace and standardising the work place.

According to Ohno (1988) there are seven kind of waste, which needs to be controlled in manufacturing industry, and they are overproduction, transportation, inventory, motion, defects, over processing and waiting. Waste is called ‘Muda’ in Japanese that means the non-value adding activities. Here is the brief description about the types of waste:

Overproduction: Too much production resulting in stock of too many inventories

Transportation: Excessive transportation results in wastage of time, effort and cost. Overproduction results in consumption of time and effort for moving goods

Inventory: Excessive inventory results in more cost, storage space and even hampers the customer service`

Motion: Unorganised workplace and unnecessary movement for the people working

Defects: Decline in quality of product, poor delivery and problems in maintaining paperwork.

Over processing: Work procedure by using the wrong tools and systems

Waiting: Inactive working people resulting in waste of time and longer lead times (time between the orders of the product until the finished good)

There are five principles of lean mentioned by Womack and Jones (1996) which are defining value as per the need of customer, knowing the value stream, improving the flow, proving what the customers want and perfection. Each of the principles are described below in brief:

Defining value as per the need of customer: The value needs to be defined from the view of the end customer

Knowing the value stream: Recognising the entire value stream of each product and eliminating waste

Improving the flow: Working on each product continuously to find out what actually is creating the waste

Providing what the customers want (Pull): Providing the products only when the customers want. Rather than producing and wasting, waiting what customer wants and orders and then working on it.

Perfection: The continuous improvement results in finding of the reasons that are causing waste

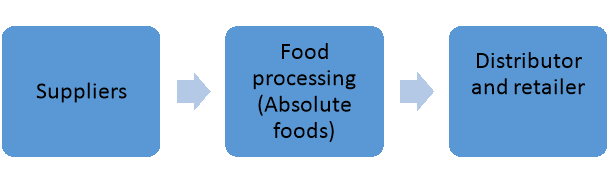

The concept of lean has proven beneficial for the manufacturing companies and the best example is Toyota. This concept can make a big impact in the food industry as well and in particular Absolute foods (AF). The figure below gives an idea of where Absolute foods are in supply chain.

Figure: Supply chain of Absolute foods

The main concern about the food processing industry is perishability, product quality and most importantly traceability. It is perishable because there is short lifespan, concerns about freshness and storage time while people expects the high quality. Packaging, chemical treatment and cold storage can be few vital steps to maintain product quality. Nabhani and Shokri (2009) mentions that the problem in the food industry is customers cannot perceive the quality but in the manufacturing company the quality is quite clear. Traceability is very important these days for the food processing businesses to be aware of the incidents like horsemeat scandal. It helps to provide the clear information about the food supplies from the place it is produced until it reaches to the end customer. According to Regattieri et al (2007) traceability is method, which helps to provide safer food supplies, and helps connect the producers and consumers. Looking at the case of AF it has been very careful about these things that is good sign for the food processing company but it is not an easy task. AF is a processor that does make sure the product reaches in high quality up the supply chain but it is also equally important how it is coming from the suppliers. For example: In the clothing industry, Primark imports all the products from its suppliers in low wages country like Bangladesh. Primark does make sure that the product reaches in good quality to the customers but how it is coming from supplier was unknown. The incident that occurred in 2013 by collapse of four-storied building took lives of more one thousand people so this kind of incidents can hamper the image and goodwill of the company. Similarly, the horsemeat scandal in 2013 is a biggest example in the food industry that reflects on why traceability is important.

Christopher and Peck (2004) stresses that supply chain vulnerability is the major problem to consider for the companies. It is further mentioned that there are mainly five kind of risks involved in supply chain especially in this modern global business days. The five risks involved are briefly described below:

Processes: Processes are the steps taken for value-adding and other managerial activities that are taken by the company. Christopher and Peck (2004) mentions that internally owned or managed functionalities, transport and other infrastructure needs to be considered very carefully to avoid process risk. In the case of AF, all beef and lamb are processed on the site in own abattoir with all carcasses inspected, stamped and labelled by HMC inspectors. To avoid process risk, company needs to consider transportation, infrastructure used in the abattoir and communication between the people that can also help to control the waste.

Controls: Christopher and Peck (2004) mentions that controls are the rules, systems and procedures that gives the picture of the company controlling on its processes. For example: order quantities, safety stock policies and transportation management. AF can have the risks of too much order quantities from the suppliers. While doing the safety stock there can be issues of spaces for storing and wastage of time.

Demand: This risk relates with the potential or actual disturbances for the flow of the product downstream. AF being a food processing industry traceability is important as mentioned earlier. The product quality and standards must be high for the customer’s demand like for supermarket chain and restaurant chain. AF have the comprehensive traceability system to ensure high standards but it might be risky if it could not trace the supplier.

Supply: This risk relates with the potential or actual disturbances upstream. For AF, as a food processing company if there is delay in supply from suppliers can create problems for fulfilling the demand.

Environment: These kind of risks can directly affect the company, whole supply chain and the market where it operates. Christopher and Peck (2004) mentions that this kind of incidents could be product contamination, accident at work, bad weather conditions and natural disasters. AF is aware of environmental risk so it has a good record on animal and livestock procurement. There is full traceability from farm to fork, local sourcing from the approved suppliers and livestock of high standards of Animal Welfare and Husbandry. It supports the local farmers and all the staff receive animal welfare training. The site also has the DEFRA approval so it is very important that the staff working in the site needs to be well trained to avoid any environmental risks.

These are the risk involved and steps that can be followed to mitigate risk for creating the resilient, traceable and transparent supply chain operations.

The main benefit of using the lean concept is it to eliminate the waste by using less resources and effort. The continuous improvement (kaizen) helps find the roots of the wastes. One of the recommendation for AF is to use JIT (pull method) because the products are perishable and producing only how much is demanded can help save lots of waste. Being a food processing company, it might not be easy because supplier also needs to have the supply when AF want it. There might occur the bullwhip effect (occurs when there is lack of synchronization in the members of supply chain) when there in unpredictable demand. The communication can be made between the staffs and all working in the different departments of the company to recognize the wastes that are not creating value for the company. This can be turned into benefits if recognized.

To avoid the environmental risks of AF the traceability needs to be tracked all the time. A small mistake can make a big effect in image of the company. The company does have proper training systems and certifications but it needs to be tracked all the time. It is hard to reach in the better position but harder to maintain the position. The other recommendation is the use of Enterprise Resource Planning (ERP) that can help AF to develop links within the company and to build external relations (Greasley et al, 2015). Greasley et al (2015) mentions that ERP concerns with internal production, distribution and financial processes and may include customer relation management (CRM), Supply chain management (SCM) and supplier relation management (SRM). For the performance measurement of AF, the use of Balance Scorecard can be important. The balance scorecard helps to attract the interest of external stakeholders by measuring the performance in context of financial, customer, business process and growth (Kaplan and Norton, 1996).

In context of AF, another recommendation is about being green. AF is the food processing company and customers today are not only concerned about food intolerance but about the organic meats as well. Beyond these, it is also about being sustainable company that cares about environment and the people working in the company. In AF, though the aim is always to provide highest standard product it would be beneficial if a framework can be developed or Total Quality Management can be implemented. TQM will help to improve the performance of AF because it is focused in customer, it involves the employee and teamwork can be developed with continuous improvement. Six sigma can be beneficial in these circumstances to identify the defects. Linderman et al (2003) mentions that six sigma is an organised and systematic method for improvement of process that helps reduce the customer defined defect rate. One of the method used in six sigma for process improvement is DMAIC (define, measure, analyse, improve and control) that helps in process improvement (Linderman et al, 2003).

KFC, a US based fast food restaurant chain has a long history of success. The secret recipe of fried chicken by Colonel Harland Sanders, which was found 70 years back, is today the most popular chicken restaurant chain. Today there are more than 20,000 outlets of KFC in 125 countries around the world selling the crispy chicken buckets and burgers. KFC has more than 860 restaurants in the UK (KFC, 2016).

The five principles to lean as mentioned by Womack and Jones (1996) are value, value stream, flow, pull and perfection. Womack and Jones (1996) mentions that the value needs to be defined from the view of end customer and failure to know the value before the application of lean technique can result in providing wrong value to the end customer. In KFC, customer gets the value of the product with what they pays for. The range of fried chicken, which covers the breakfast, lunch and dinner are provided to the customer in affordable price. Some of the KFC also provides halal chicken targeting the Muslim community. The problem is there might not be good customer service but the customer complaints are handled carefully. For example: If the food is cold, it is exchanged and in some cases refunded. Value stream is about recognising the entire value stream of the product and eliminating waste. The chicken for the KFC comes from the same suppliers that supply to the major supermarkets. KFC also make sure that the chicken are traced from farm to the restaurant by providing a unique supplier code and batch number for each bird.

Improving the flow is about finding what actually is creating the waste. In KFC, food waste is the biggest waste. Sometimes overproduction of the chicken when there is unpredictable demand creates lot of waste. To minimise the volume of waste KFC has started the reuse scheme, which distributes the unused cooked food to the charities. Other type of waste can be waiting in a sense that the staff some time has nothing to do and waste the time that in a sense is not creating any value to the company. Again, when there is short of staff the lead-time between the order and the delivery to the customer takes longer. Normally the lead-time target of KFC is to deliver the food to customer in a minute once it is ordered. Pull refers to providing only when the customer wants it or after the end customers order the product. This is quite impossible in the fast food restaurant like KFC. The demand is very unpredictable and is only dependent on the previous records of sale. KFC needs to be very careful while ordering especially the perishable products like chicken and meat items. The other thing is it needs to prepare some amount of chicken all the time and there is time limit for the cooked products. Once the temperature is below what it needs to be it goes to the waste.

Perfection is the step where continuous improvement results in finding of the reasons that are causing waste. KFC does tries many ideas for controlling waste but it seems it is very hard to apply this in the fast food restaurant. For example: When the restaurant is quiet then to save the cost and control the waiting wastage the staff gets sent home and what if it certainly gets busy again. The overproduction is hard to control because the demand is very unpredictable. Too much cooking creates the wastage and less cooking results in longer lead-time for the customers. The delivery time is also a non-value adding activity because sometimes if delivery is late the company lose the business from the product that are out of stock.

According to Melton (2005) the benefits of being lean are reduced inventory, less processing time, reduction in lead-time, cost saving, reduced inventory and less rework. In KFC restaurants, it started the one-minute waiting time to avoid the customer for waiting long and efficient working by removing queues. Melton (2005) also adds that the lean thinking forces to review the whole supply chain and finds out the bottlenecks and inefficiencies. Christopher (2011, p. 139) mentions that bottleneck is the slowest activity in the chain which could be machine or also the part of the information flow like order processing. The supply chain of the KFC is it receives the chicken from the suppliers that comes in the store and is prepared freshly to serve the customers. The bottleneck can be delivery time, staff turnover and the frying machines for the stores. Traceability is important because there was an incident in a store in meadow bank about the halal chicken resulting in closure of store for few days.

Following the lean green, KFC focused in its packaging materials to be recyclable and sustainable, replacing the palm oil by rape seed oil and sunflower oil that is used for frying chicken, food waste to be recycled by donating to local charities, reduce the total energy per customer by 20% by 2020, turning wastage oil into bio diesel, send the 5% of wastes for landfill and reduced CO2 emissions from constructing materials. Communication and relation between the staffs are essential for which staff party and together are done from time to time.

|

Abdulmalek, F. A., & Rajgopal, J. (2007) Analyzing the benefits of lean manufacturing and value stream mapping via simulation: A process sector case study, International Journal of production economics, vol. 107(Issue 1), pp. 223-236 Christopher, M. (2011) Logistics and supply chain management, 4th edn, London, Pearson Limited Christopher, M., & Peck, H. (2004). Building the Resilient Supply Chain. The International Journal of Logistics Management, vol. 15(Issue 2), pp. 1-14. Emiliani, M. L. (2006) Origins of lean management in America: The role of Connecticut businesses, Journal of management History, vol. 12(Issue 2), pp. 167-184. Greasley, A., Moles, P., Mangan, J. and Reid, D. (2015) Operations management and corporate finance, John Wiley and Sons, Inc Hines, P., & Taylor, D. (2000) Going lean. Cardiff, UK: Lean Enterprise Research Centre Cardiff Business School, pp. 3-43. Hines, P., Holweg, M., & Rich, N. (2004) Learning to evolve a review of contemporary lean thinking, International journal of operations & production management, vol. 24(Issue 10), pp. 994-1011. Kennedy, I., Plunkett, A., and Haider, J., (2013) Implementation of Lean Principles in a Food Manufacturing Company, in Lecture Notes in Mechanical Engineering, Advances in Sustainable and Competitive Manufacturing Systems, pp. 1579-1590 KFC (2016) our food [Online] Available at http://kfc-csr.co.uk/food/our-suppliers.html Accessed 1 November Linderman, K., Schroeder, R. G., Zaheer, S., & Choo, A. S. (2003). Six Sigma: a goal-theoretic perspective, Journal of Operations management, vol. 21(Issue 2), pp. 193-203. Melton, T. (2005). The benefits of lean manufacturing: what lean thinking has to offer the process industries, Chemical engineering research and design, vol. 83(Issue 6), pp. 662-673. Nabhani, F., and Shokri, A. (2009) Reducing the delivery lead-time in a food distribution SME through the implementation of six sigma methodology, Journal of manufacturing technology Management, vol. 20(Issue 7), pp. 957-974. Rothenberg, S., Pil, F. K., and Maxwell, J. (2001). Lean, green, and the quest for superior environmental performance. Production and Operations Management, vol. 10(Issue 3), pp. 228-243. Kaplan, R.S. and Norton, D.P. (1996) The Balanced Scorecard: Translating strategy into action, Harvard Business School Press |

Ohno, T. (1988) Toyota Production System Productivity Press, Portland, OR.

Regattieri, A., Gamberi, M., & Manzini, R. (2007) Traceability of food products: General framework and experimental evidence, Journal of food engineering, vol. 81(2), pp. 347-356.

Shah, R., & Ward, P. T. (2003). Lean manufacturing: context, practice bundles, and performance, Journal of operations management, vol. 21(Issue 2), pp. 129-149.

Womack, J. P., Jones, D. T., and Roos, D. (1990) Machine that changed the world, Simon and Schuster.

Womack, L. and Jones, D., (1996) Lean Thinking, Simon and Schuster, New York, NY.