Cost Estimation for Meeting Perth’s Water Needs

(a) Introduction

2.1 This career episode is based on my engineering activity at the University of Western Australia. It is about an assignment I carried out during the second semester of my master’s degree in the unit “Process synthesis and design”, worth 25 % of the overall grade. The assignment was released on 11 August 2015 and was due on the 18 September 2015.Thus the entire task was completed in just five weeks’ time.

(b) Background

2.2. The project on “Cost Estimation for Meeting Perth’s Water Needs” was carried out as an assignment for the unit ‘Process Synthesis and Design’. I was part of a group of six people. The project required the calculation of CAPEX and OPEX for two different scenarios and comparison of both to determine the suitable one for real life implementation. This assignment involved several design stages along with the study of flow in a pipeline in order to select the appropriate piping and the length required to meet the water requirement over a 50 year lifetime. The project was completed successfully under the guidance of Prof. Mike Johns, School of Mechanical and Chemical Engineering at the University of Western Australia.

2.3 Decreasing annual rainfall and subsequent decrease in water supply had become the talk of media and local government in Perth. This has caused an interest in techniques to supply fresh water to Perth. The project aimed at evaluating two different scenarios to meet with Perth’s increasing water demands. The first scenario considered in the project was a two stage RO Desalination plant that would intake seawater and produce fresh water at 1000 ð‘€ð¿/ð‘‘ð‘Žð‘¦. The second scenario was the design construction of a 2435 km Kimberly pipeline from Argyle dam to Perth capable of meeting the same fresh water requirement per day.

2.4 Some of the core duties I was involved in are as follows:

- I performed literature reviews and referred several materials to understand various prospects of the project.

- I divided the task among my team members and ensured that they accomplished their assigned tasks effectively.

- I estimated the CAPEX and OPEX for two different scenarios.

- I contributed to the discussion with the members of my team on the merits and demerits of each case of the project.

- I attended meetings with my supervisor and team members to discuss the progress of the project and to exchange our contributions.

- I also compared and validated certain theoretical results with that of my calculated ones using appropriate approaches to suit the requirements of the project.

- I welcomed the challenge in completing a cost breakdown analysis by selecting the appropriate material based on its mechanical properties, pressure head, volumetric flow rate, velocity and followed by certain significant assumptions throughout the project.

- I prepared charts and tabulations of selection and cost analysis for different equipment and materials.

- I also prepared a report on the comparison of CAPEX and OPEX of two different scenarios and contributed more towards the design of reverse osmosis desalination plant and its functions.

(c) Personal Engineering Activity

- The assignment required the comparison of CAPEX (Capital Expenditure) and OPEX (Operational Expenditure) for two scenarios. The first scenario given was the reverse osmosis desalination plant. This process consists of several stages. I analyzed the process to determine the amount of feed required to produce 1000 ð‘€ð¿/ð‘‘ð‘Žð‘¦ of fresh water. I discovered that from the 45% recovery of the RO membrane system, a 2222.2 ð‘€ð¿/ð‘‘ð‘Žð‘¦ of salt water feed will provide the required 1000 ð‘€ð¿/ð‘‘ð‘Žð‘¦ of fresh water to Perth.

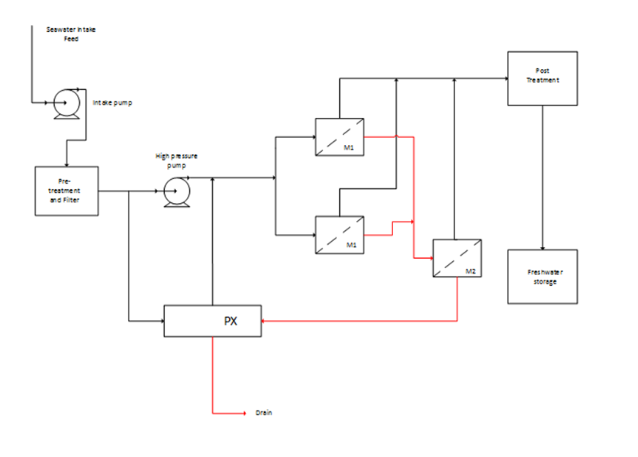

Figure 1: Reverse Osmosis design selection block diagram

2.6 In order to determine the OPEX, all the steps involved in the process had to be accounted. In order to do so, I broke down the process into independent steps. The first step was the pre-treatment of feed water to avoid fouling in the membrane system. Managing membrane fouling with pre-treatment methods reduces the replacement rate of membranes and lowers the ongoing OPEX costs. The next step involved in the process was coagulation. I chose Ferric Salts as a coagulant because of its tendency to disinfect microorganisms, partially degrade and oxidize the organic and inorganic impurities, and remove suspended particulate materials in a single dosing and mixing unit process. The next step in the process was the passage of feed water through Dual-filters. After extensive research, I decided that the Anthracite bed on silica sand was best suited to remove suspended solids and colloids formed in the ferric salt treatment. Lastly the feed was passed through micron cartridge filters to remove fine particles and bacterial matter before it was processed through a high pressure pump to the membranes.

2.7 The final and the most important step of the process was the selection of membrane. Referring to a number of papers, I found out that the best suited membrane for the specific purpose was the Toray TM820-440 membranes. These membrane elements had a high salt rejection percentage, large flux, low cost and are efficient on energy use to minimize OPEX costs. Before distribution, the permeate needs to be treated to maintain pH and remove corrosion potential. Lime contactors can increase hardness, alkalinity and pH while preventing calcium to leech from pipes into the distribution system.

2.8 I prepared the CAPEX by scaling up the capacity of an existing desalination plant to match the desired capacity. I considered The Perth Seawater Desalination Plant in Kwinana which has a capacity of 45ðºð¿/ð‘¦ð‘’ð‘Žð‘Ÿ and incurred a capital cost of $387 million AUD. I also took Southern Seawater Desalination Plant into consideration in Binningup which had a capital cost of $1400 million AUD and produces 100 GL/year. Of the two, I selected the Binningup desalination plant as it was built much more recently compared to that of kwinana. From calculations, I found that the proposed plant is 3.65 times larger than the Binningup plant and as such, the CAPEX could be approximated to $5110 million AUD.

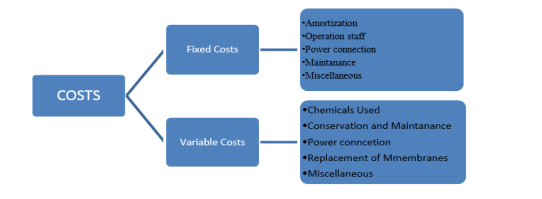

2.9 Operating Costs can be classified as fixed or variable.

Figure 2: Operating expenditure classification used in the project

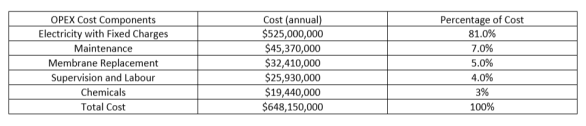

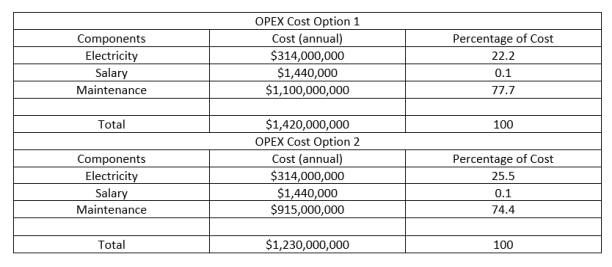

The table below summarizes the OPEX estimation for the Desalination plant.

Table 1: Summary of RO Desalination OPEX Cost Components

- 2.10 The second scenario to be considered was the Argyle Dam Pipeline. The solution costs were based on quotes from two Australian companies: Steel Mains and Flowserve. I selected these two companies based on a background study that I carried out. From the research, I learnt that these companies have been involved in numerous Australian water transport projects and abide by Australian standards. The final solution that I selected was based on Steel Mains cement mortar lined pipe model DN2200 and custom made pumps designed by Flowserve with an operating head value of 250 metres with inlet and outlet valves equal to the diameter needed. The 250 metres operating head was chosen as the pipes are designed to work at 2.7MPa.

-

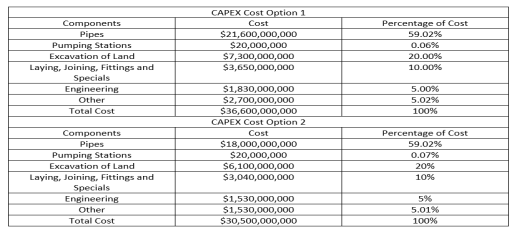

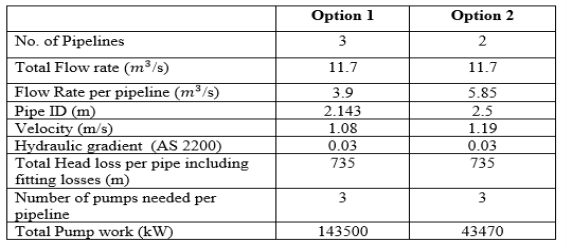

After discussion with the team members, two solutions were proposed: a real pipeline with outer diameter of 2159mm, 3 pipelines with 3 pumps per pipeline, and the other one having theoretical pipelines with outer diameter 2520mm, 2 pipelines with 3 pumps. The CAPEX estimation for the proposals is as follows:

Table 2: Summary of Pipeline CAPEX Cost Components

- The OPEX estimation has been limited to the power requirements of the pumping stations and the personnel required to run the pipeline.

Table 3: Summary of Pipeline OPEX Cost Components

- I compared the CAPEX and OPEX along with the advantages and disadvantages of both the scenarios to determine which of the two would be more suitable for real life application. For the Kimberley pipeline, the CAPEX cost ($36.6 billion AUD) heavily exceeds the desalination plant. This large CAPEX cost comes from the cost of purchasing DN2200 pipes which have an estimated lifetime of 100 years. The major factor contributing to the OPEX value from the pipeline is maintenance (77.7%). On the proposed desalination plant solution, the CAPEX cost is relatively low compared to the pipeline ($6.275 billion AUD). The majority of this cost comes from the installation of high pressure pumping station, and a seawater desalination system with energy recovery devices which are a long term investment to save on high energy costs of up to 50-60% associated with desalination. The majority of OPEX estimates come from the cost of power to run the plant (81%). Considering all the facts, I decided that the desalination plant should be selected over the Kimberley project. This is because the desalination plant is more economically feasible over a large time span. Even though the pipeline has been designed to facilitate this increase in demand, CAPEX estimates are too expensive to justify this project.

- I also carried out several calculations to determine the velocity of water running through the selected pipelines and was found to be 1.08 m/s.

Table 4: Information summary of real (calculated values) and theoretical pipeline options

Parameters such as Reynolds number, relative roughness, pressure drop, volumetric flow rate and pipeline elevation were also determined when selecting the appropriate pipeline for this project. Estimating the appropriate number of pumping stations at remote areas along the length of the pipeline was one of the tedious task in the project as it involved a lot calculations and literature reviews. A different approach to this project was the consideration of solar technology over wave supply to be the best present day strategy at remote areas as the supply of power to pumping stations was not be a viable option by the latter. Unfortunately, these winds are not a reliable option in the interior parts of Western Australia and so would not be a feasible selection for power supply to a potential pipeline. Overall, I was able to achieve all the objectives of the project successfully within the specified time and prepared a final report incorporating all the necessary design calculations, ideas and suggestions which could have improved the overall outcome of the project. A peer review was also submitted at the end of the project as a reflection on how each team member contributed individually for the project.

(d) Summary

2.15 This project provided me with a valuable experience and great insight into an industrial project. I gained profound knowledge on process economics and also helped boost my confidence. During the course of the project, I understood the importance of team work and team management. I utilized my engineering knowledge for the successful completion of the project and as a whole, this project served as a stepping stone into the industrial world.