Design of Supply Chain Analysis

|

Supply Chain and Operations Management |

|

Wu Wuyang |

|

Kate Barnett-Richards |

|

9/1/2017 |

Contents

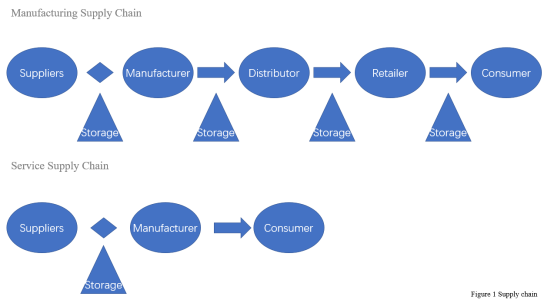

Supply chain management (SCM) is the combination of art and science that goes into improving the way your company finds the raw components it needs to make a product or service and deliver it to customers. (Wailgum, 2007). So, the supply chain is suit for all the company in the world. Wherever they provide the service or manufactured product. In the text, I will go to choose one manufactured product and one service product and the Figure 1 show the supply chain model for both. For the manufactured product is going to be iPhone 7 from Apple Inc and the service is delivery service provide by TNT Post Group. The product them provide by well-known brand in the world. Therefore, this essay will be going to compare and analyse the overall design of the supply chain and how decisions are made. Also, the role for the consumer and how importance of quality in the supply chain.

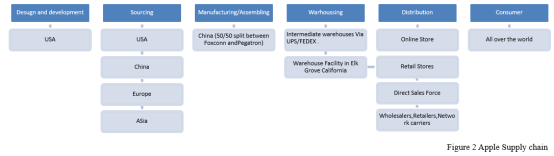

Apple is an American multinational company, one of the world greatest, design and manufacturing of consumer electronics and computer software products. (The Editors of Encyclopædia Britannica, 2015). The figure 2 show the supply chain model for iPhone 7. As we can see from the suppliers the company choose the raw materials from many different place and built in China. Because of the labour in China is the cheapest in the world. They also leave the work in two different companies. So, that they can ensure that working in a short time can finish it on time. After the iPhone 7 has been made, they will deliver the products to the warehouse in California or in the intermediate warehouse. And then, they will wait for the first time selling data and prepare to sell. After few weeks, the consumer can receive the product if they ordered online. On the other hand, customer can buy the product in the shop. During this supply chain, the company must make sure the distribution basis on the role customer played. As we can see, Apple company is fit with the traditional model. Also, iPhone 7 have some weakness. For example, the prices are quick high, not the most people can pay for it. Due to the prices, will be the weakness for the iPhone 7. On the other hand, advanced technology was using in the that product such as AirPods. That also affect the customer. That was more than 300,000 people have signed a petition urging apple not to ditch the headphone socket from iPhone 7. (Wakefield, 2016). Cause that lots of fans was really about that. Those two weaknesses for iPhone 7 is the prices and the Airpods. In this way, Apple company changed the charger port a few years ago, and people got upset. but that won’t stop people buying it. (BBC, 2016). Therefore, Apple company supply chain is sustainability. Problems about apple company they really can do is cut the prices or to prove to customer the product they buy is valued.

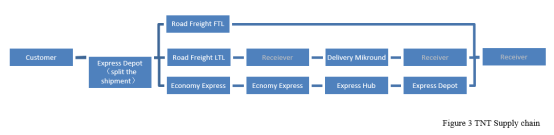

TNT post group N.V. (TPG) provides domestic and international mail service, express distribution, and logistics services. It includes the Dutch postal service, this is the first such service is part of a listed company and is considered one of the most efficient postal operators in the world, providing 22 million emails a day. (Encyclopedia 2016). As we can see the figure 2. TNT have three different deliver line for the services. One is for the economy express, one for the freight FTL and one for the freight LTL. Even they have three different type of the service, but all of them is same. That is all about the delivery service. That is going to meet the customer needs. For example, economy express is for the normal people want to deliver a small parcel, so they will choose economy express. Second, freight FTL is for a company need delivery a product, and they need a full truck to do it. Third, freight LTL is for the company to deliver a product need truck but only less truck. Therefore, TPG have traditional model of the supply chain as the figure 1 shows. Supplier, warehouse, destruction to the different level of services and end with the receiver. Every company have some weaknesses. For example, firstly they have so many competitive company, like DHL, FedEx and UPS. Second, TNT Express, there is a poor customer service centre to provide slow response to customer. That will loss of the customers. So, they need to improve the better customers services centre and keep the customers giving the job to them.

Comparison Apple Inc and TNT Post Group from the Supply chain. They all fit with the traditional model. Second, the weakness for Apple Inc is more about the Final product and for TNT Post Group is more about the process. They all have a way to improve they product or services.

The role of the consumer and the decision making is influence each other. For instance, from Apple Inc they always set up the countries list for getting the handset first. Stand by the role of the consumer they will not happy about their country not on the list. So, they will have two kinds of psychological. One is not going to buy it and second one is found a way to buy it. As we can see Apple decision is set up a list of the countries affect consumer. When the consumer been affect by the Apple, the supply chain for the apple will be changed. They will affect every involved with warehouse and the distribution in the supply chain. Even the role of the consumer played can influence the company but in this case consumer do not shape supply chain strategy.

In the other hand, for the TPG delivery services. In the supply chain of the services the consumer just like a supplier. The consumer really giving the job to the company and shape supply chain strategy. They are so many delivery company around the world. When the customer want deliver a parcel and they will compare with many different. The prices and the services will affect them to pick the company. Thus, every decision the company made will impress the supply chain model. Moreover, every decision TPG made firstly they need to thinking about the consumer and then they should think about the warehouse and different services requires diverse of the services levels.

Every decision made will decrease or increase in supply. Increased number of the producers will be decreased production costs. On the other hand, decrease reduced number of producers will be increased production costs. Besides decrease or increase in demand also have different result. Decreased number of consumers will down in income levels. And the increased number of consumers will up in income levels. Thus, more product customers want more income they will get and more supply they need will cut every unit costs. We also have push and pull system in the supply chain. “Push type” means “make-to-stock,” in which the production is not based on actual demand. “Pull type” means “make-to-order.” (Lean Manufacturing Japan) And the manufacturing product more fit with the push system and services will be more apply for pull system. Just like iPhone 7 built without having a specific customer request. TPG provide services only if there is a request for a product by the end of receiver. “As we go through the exercise of determining what the “as is” engineering needs to be to close the gap to become what “to be” state, we can collect and document what the strengths, weaknesses, opportunities, and threats (SWOT analysis) to the vision are and will be”. (Sherman, 2012). First, the strength for Apple Inc is horizontal and vertical integration has a huge competitive advantage and TPG is robust delivery base. Second is the weakness, for Apple Inc is highly dependent on iPhones and iPod product line and TGP is a weak financial performance is highly dependent on infrastructure. Third is opportunities, for Apple Inc is Apple pay provides strong growth opportunities and for TPG is global air freight department express positive outlook for growth, Courier and parcel market. Finally, the threats for Apple is premium pricing can restrict the growth of emerging markets and for TPG is electronic alternative.

`Shewhart did defined quality as the “goodness” of a product in 1931. ` And defining quality around product based, user based, value based and manufacturing based criteria.

Wailgum, T., (2007) Supply chain management definition and solutions. Available at: http://www.cio.com/article/2439493/supply-chain-management/supply-chain-management-definition-and-solutions.html (Accessed: 2 January 2017).

The Editors of Encyclopædia Britannica (2015) Apple Inc. | American company. Available at: https://www.britannica.com/topic/Apple-Inc (Accessed: 5 January 2017).

Wakefield, J. (2016) Fans angry over ‘missing’ iPhone 7 headphone socket. Available at: http://www.bbc.co.uk/news/technology-36606220 (Accessed: 6 January 2017).

BBC (2016) Apple’s iPhone 7 ditches traditional headphone socket. Available at: http://www.bbc.co.uk/news/technology-37277965 (Accessed: 6 January 2017).

Encyclopedia (2016) International Directory of Company Histories. Available at: http://www.encyclopedia.com/social-sciences-and-law/economics-business-and-labor/businesses-and-occupations/tnt-post-group-nv (Accessed: 6 January 2017

Ghosh, A. (2016) Apple iPhone 7 pre-order: Here are the countries that will get the handset first. Available at: http://www.ibtimes.co.uk/apple-iphone-7-pre-order-here-are-countries-where-flagship-available-first-lot-1580459 (Accessed: 7 January 2017).

Roser, C. (2015) The (true) difference between push and pull. [online] Available at: http://www.allaboutlean.com/push-pull/ (Accessed: 7 January 2017).

Corporation, A. (2008) Push-pull manufacturing. Available at: http://www.lean-manufacturing-japan.com/scm-terminology/push-pull-manufacturing.html (Accessed: 8 January 2017).

Sherman, R.J. (2012) Supply chain transformation: Practical Roadmap to best practice results. United States: John Wiley & Sons.

Apple Inc. SWOT Analysis. (2015) `Apple, Inc. SWOT Analysis` writing 1-10, Sept. 18, 2015.

TNT Express N.V. SWOT Analysis. (2015) `TNT Express N.V. SWOT Analysis` Writing 1-8, Dec. 21, 2015.

Crosby, P. (1980) Quality is Free. London: Penguin Putnam

Shewhart, W. (1931) Economic Control of Quality of Manufactured Product. Milwaukee: ASQC