Design Proposal for Smartphone Technology

Â

HUMAN MOBILE

“Your personal invisible communication platform”

Â

Â

Table of Contents

Â

The goal of this project is to propose an innovative and futuristic design of new era mobile smartphone. It is been suggested that the whole device will be implanted to the human body. The aim of the following analysis and key points are the correct choice of the right materials for the task, with focus on the biocompatibility and the practicality of them.

Due to the introduction of the smartphone as we know it nowadays, our daily routine has considerably improved. With a device that fits in a pocket, it is possible to communicate instantaneously with anyone that has an internet connection everywhere on the planet, use it as a precise navigator while a couple of years ago it could only be done with a separated device, make payments through i-banking and not wasting valuable time during the day to deal with common banking transactions and the list goes on and on.

It is not unreasonable to say that a strong bond is developed between the user and the mobile phone. People are rarely separated from their mobile phones and use them consistently. The constant use and dependence to the mobile phone can lead to several problems which are: the requirement of carrying the device permanently, the limited battery life although the progress made the need of carrying a charger or a power bank and finally, there is the probability of theft (especially if it is a high value device) leading to the exposure of private data.

The introduced design can provide total privacy, a fabulous experience in video streaming through a contact lens and leaves the word “charging” back to history.

3.1.   Problem scope

“Human Mobile” is a series of the micro-devices implanted into the human body, through signal transmittance from each component to achieve several functions. There are many problems to take in consideration, which are:

•   Each device should have a relatively long life span.

•   Reduce potential radiation.

•   Excellent thermal diffusivity.

•   Bio-compatibility.

In conventional mobile phones, replacement the rate of the old generation by the recent one is frequent, “human mobile” focus on providing customer privacy and latest technology. All the devices will be implanted in the human body, so the product must be designed with a long life span. Radiation is a potential problem that many people care about, due to fact that high amounts of radiation can provoke cancerogenesis. All devices should have an excellent thermal diffusivity allowing quick heat evacuation to reduce the possibility of the devices overheat that can lead to an explosion. The most significant problem is to secure the bio-compatibility of all the parts. Nobody wants to implant an instrument in the body that can cause health issues even though it is convenient.

The above parameters will affect the selection of materials. All materials must meet the conditions mentioned above.

3.2.   Design requirement

The “human mobile” consists of five main components: an ultra-thin micro Bluetooth speaker implant in the ear; a photo visual processor, in the shape of a contact lens, making it easy to put on and take off; a pressure sensor, that acts as a keyboard and mouse; a circuit board containing microchip, acting as the “brain” of the “human mobile”, responsible for transmitting signals between the processor and the outer world, it will be implanted in arms; a battery to provide electricity current, it will be implanted under the foot. All these devices will be covered by a radiation-reducing coating material, at the same time; the coating material must also have excellent thermal diffusivity.

2.2.1.   Ultra-thin micro Bluetooth speaker

Micro Bluetooth is implanted behind the ear, it should be as thin as possible, and the level of sounds should be lower than normal Bluetooth speaker, because high volume noises will harm the ear.

2.2.2.   Photovisual processor

The Photo visual processor is a contact-lens like processor, a micro OLED screen included in to provide digital photo during use, the digital photo connects with the processor sensor, and the customer enjoys an experience of touch-screen everywhere. The processor must be comfortable to the eyeballs.

2.2.3.   Pressure sensor

A pressure sensor implanted in the fingertip, with a microchip attached as well and according to the change of pressure from the fingertip, the pressure sensor catches the signal and the microchip process it then sends the signal to the visual processor. The sensor should be as tiny as possible to implant in the fingertip.

2.2.4.   CPU

This is the most important part of the “human mobile”; normally a CPU is occupying quite a large size when implanted it in the human body, so the implanting position must be a seldom used area, like arms or legs. At the same time, the CPU board should be relatively flexible to resist and absorb hits and shocks from the external environment. The size of it should be as small as possible.

2.2.5   Battery

A battery is needed to provide current to each component. The battery must be able to provide adequate current, and at the same time to generate current as well. A piezoelectric battery is chosen; it can generate current by compression. The battery will be implanted under the foot, so people can generate current by walking.

2.2.6   Coatings

The coating material is used to cover every facility that is implanted in the human body. It must be bio-compatible and non-toxic. Moreover, during the selection of the coating material, a radiation-reduced material is preferred.

3.3.   Design description

When customer using “human mobile”, the CPU will send/receive signals at first, and then transmit these signals into voice/visual form to micro speaker/visual processor. When the user would like to reply at messages, he can easily use his finger tip to type messages through a lighten keyboard provided by the visual processor. Also more entertainment purpose functions can be achieved by these facilities.

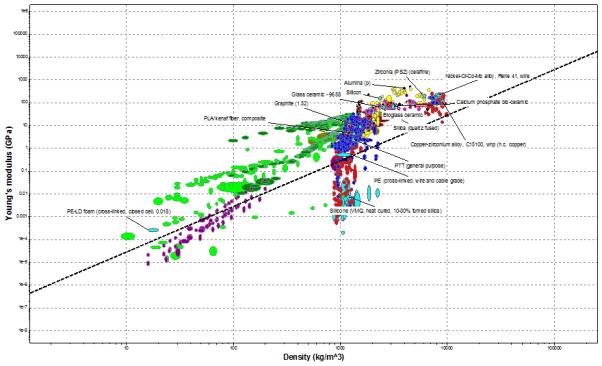

For “human-mobile” design, a combination of cost efficiency, electrical properties, thermal expansion and density are crucial. Biocompatibility for each material is not particularly included because the electrical component will be coated with a biocompatible coating. All of those considerations were put together for an Ashby diagram to be constructed.

To reduce the price for implanted surgery, the price for each material is constraint to be no more than 25₤/kg while the density has its limit below 10g/cm3. Various materials from each group were selected for six major parts of the design based on the diagram in Figure 1.

Figure 1. Ashby Diagram

4.1Microprocessor

Every device has a brain to control its functions. It builds-up from four main parts into one, known as microprocessor. These parts are: transistor, resistor, capacitor, and diode. According to WhatIs.com (2015), transistor is a device that controls the flow of current and voltage, acts as a switch on/off gate for electronic signals. Conductive materials like metal will easily transfer the electrical flow without control, while isolator materials like plastic will transmit neither current nor voltage. Semiconductor is the perfect material that able to transport the electrical flow and control it[1].

Radio-electronic.com (n, d) listed some of semiconductor materials that are widely used in electronic devices. Germanium is on the top list, and placed on the second but is the most used for electronic devices [2]. Even though the charge carrier mobility is less than germanium, it offers a lot easier manufacturing process, exists as the second most abundant elements on earth, hence more efficient cost for production [3].

The second component is the resistor. Resistor has a specific and unchanging resistance that will limit the flow of electrons through the circuit [4]. The different point between a resistor and a transistor is that the fist only consumes the power but cannot generate it like transistor, thence it is a passive component. Materials used for making a resistor can be divided into two parts, the wire and the core. The wire usually made from carbon, metal alloy (nickel-alloy), metal oxide or foil. Meanwhile, the core often made from ceramic, fiberglass, or carbon [5].

To store the electrical charge of electronic devices, capacitor is used. Capacitor is made from conductive and dielectric material. Dielectric material is a non-conductive substance that determines the properties of capacitor. SCHOOT (2014) stated, glass ceramic is a pore free material which able to assist high dielectric strength and provide a high storage density. It is very suitable to be applied as a capacitor, especially if manufactured in nano-sized crystalline structure [6].

Finally, the last component that controls the microprocessor is the diode. It functions as a controller of which direction the current flow, prevents damage to the circuit due to back flow or electromotive force, and consist of cathode and anode [7]. It also provides time lag to stabilize the power within the circuit. Diodes usually are made from semiconductor materials like silicon. Electrons in P-type and N-type of silicon attracted with each other, they tend to build up until it prevents the free movement of any further electron [8]. To increase the conductivity of the circuit, copper or gold are deposited by electroplating process [9].

For this design, the materials chosen for the microprocessor are silicon for both transistor and diode, fibreglass for the substrate of resistor and nickel alloy for its wire and glass ceramic for the capacitor. Properties of selected materials are summarized in table 1.

4.2Battery

To provide electricity for the component to work, efficient battery which provide enough energy needs to be chosen. Considering biocompatibility of the component, green energy were chosen for the design. One of the options is piezoelectric a material. “Piezoelectric” can be defined any material, which converts kinetic energy into electricity. The atoms inside the piezoelectric crystal are arranged in an unsymmetrical way but however their charges are balanced [10]. Applying mechanical force into the crystal will disturb the arrangement and misplace the atoms, creating net electrical charges. Utilizing its feature, a piezoelectric device can supply self-sufficient energy system.

Piezoelectric materials can be found in either natural or synthetic. Natural crystals which exhibits this characteristics are quartz, topaz, and Rochelle salt (potassium sodium tartrate)[10]. Synthetic ceramic materials with a perovskite crystalline structure are materials such as Lead Zirconia Titanate (PZT) or more environmental friendly lead-free piezoceramic. One example of lead-free piezoceramic material that shows big potential is Potasium Sodium Niobate (KNN).

Figure 2. How Piezoelectricity Works[10]

KNN based piezoceramic shows competitive value of dielectric constant (driven charge per unit force applied in the parallel/perpendicular direction) for about 9.01-13.81 F/m (10-9) compared to PZT 15.3-16.59 F/m (10-9)[11]. From medical aspect, bone can be categorized as piezoelectric material because apatite-collagen relationship can be assumed like p-n junctions[12]. Cytotoxities of KNN have also been evaluated and viability of mouse fibroblast cultured for 24 h were respectively 84%, which means the ion dissolution relatively controllable[12]. Alternative material, for example quartz or the synthetic version of it is fused silica, which has high purity silicon. It has been used for many medical instruments due to its inert properties and biocompatible with humans’ body[13]. Comparing between KNN and quartz, it is more costly efficient and superior properties to use quartz than KNN.

Table 1. Properties for electrical material

|

Materials |

Density/ gcm-3 |

Thermal expansion coefficient/

|

Electrical resistivity/

|

Dielectric strength/ MVm-1 |

|

Quartz |

2.20 |

0.48 – 0.52 |

3.16e24 – 1e26 |

25 – 40 |

|

Glass ceramic 9658 |

2.52 |

8.72 – 9.07 |

3.16e19 – 3.16e20 |

38 – 40 |

|

Silicon |

2.33 |

2 – 3.2 |

1e6 – 1e10 |

5 – 12 |

|

Graphite |

2.23 |

7 – 7.59 |

276 – 348 |

|

|

Copper C15100 |

8.94 |

16.8 – 16.9 |

1.91 – 2.04 |

|

|

Germanium |

5.32 |

5.9 |

1e5 – 5e7 |

16 |

|

Gold |

19.3 |

14.2 |

2.44 |

|

|

KNN |

4.1 |

6.5 |

8e6 – 5e8 |

1.3 |

4.3      Speaker & OLED

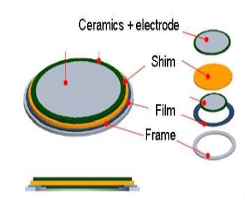

As for a speaker used in the “human mobile”, the ultra-thin speakers were chosen. Piezoelectric speakers are chose for the reason they are much thinner than the speakers normally used in mobile phones [14]-[16]. In the design of human mobile, we used a kind of piezoelectric speakers with a good sound quality and with a thickness of 0.9-mm. This kind of ultra-thin speaker mentioned in this design has already been successfully used in slim mobile phones nowadays.

The ultra-thin piezoelectric speakers are made up of 4 sections, single-layer piezoceramics, shim materials, an elastic polymer and frame, as the picture shown below.

Figure 3. Piezoelectric Speaker  Figure 4. OLED 4 layers

Both sides of the speakers are covered by a silver electrode. Zirconnia and ceramics with an advantage in thickness is used as the piezoceramics layer [17]. Copper is used as the shim material and the surfaces of the copper are covered by the piezoceramics. This kind of section is used to construct a bimorph transducer. PTT film is placed between the 0.9-mm-thick frame and shim, and the bimorph transducer was then attached to the frame. In the selection of materials, the most important aspects we have to consider about are the thickness, density, thermal expansion coefficient, and electrical resistivity.

An adhesive is used in the construction to connect all the materials together, and an ultra-thin speaker is created by arranging in a concentric circle .

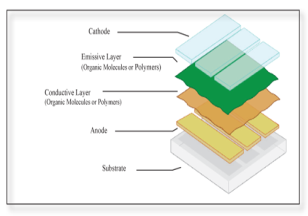

OLED is used in the construction of human mobile. Its principle is that through the smallest details of chemical structure or processing make the devices lighten and display. The construction of OLED is made up of 4 sections, cathode, emissive and conductive layer, anode, and substrate. The following picture shows us the details of an OLED.

According to the application, though there are many options for each layer, we choose the materials with better properties and lower price. We choose high density porous polyethylene (HDPE) as anode [18], for the reason of its high density, and for the material selection of cathode, often calcium which satisfies the conditions under the construction of OLED. The anode, of course, must be transparent so that the emitted photons can exit the device. As consider the human mobile is a flexible device [19] so we choose Polyethylene as the materials of emissive and conductive layer. When we talk about materials selection, we talk about how does this product works, what is this product’s function, what requirements we need to meet, what materials we choose.

Table 2. Properties of the materials used in speakers

|

Materials |

Density/ Kgm-3 |

Thermal expansion coefficient/ strainoC-1 |

Electrical resistivity/ ohm.cm |

Dielectric strength/ MVm-1 |

|

Zirconia |

5.99e3-6.11e3 |

7.8-8.1 |

1e17-3.16e18 |

4-6 |

|

Copper |

8.94e3-8.95e3 |

16.8-16.9 |

1.91-2.04 |

— |

|

PTT |

1.3e3-1.33e3 |

138-142 |

1.43e22-8.4e22 |

31.4-32.6 |

|

Aluminum |

3.94e3-3.96e3 |

7.7-8.5 |

1e19-3.16e20 |

10-21 |

Table 3. Properties of the materials used in OLED

|

Materials |

Density/ Kgm-3 |

Thermal expansion coefficient/ strainoC-1 |

Electrical resistivity/ ohm.cm |

Dielectric strength/ MVm-1 |

|

HDPE |

920-1.24e3 |

176-184 |

2.37e23-2.13e24 |

24.4-29.9 |

|

Calcium |

3.05e3-3.15e3 |

11.4-14 |

— |

— |

|

Polyethylene |

134-160 |

111-123 |

6.31e21-4.26e22 |

— |

|

LDPE |

16-20 |

190-220 |

1e21-1e23 |

4-6 |

4.5. Pressure sensor system

The pressure sensor system is used to measure the pressure parameters which are being tested, which have been divided into two parts.

The first part is the main part, pressure sensor, which is made of silicon (a traditional material for sensor) aim for receiving force signal. The second part is a small microchip which process signal and send it to the CPU. The material of the second part is same as the main microchips.

The whole pressure sensor system acts as a “mouse” to achieve the “anywhere touch-screen” function through visual processing lens signal.

4.6. Coating materials

A coating material is used for protection. Because our products need to be implant into human the body, we need an absolutely safe coating to prevent harmful accident happening.

The coating must meet the standards which are: bio-compatibility, very slow or no degradation, and good surface properties.

So, a choice of three kinds of materials has been made for the customer. First of all is bio glass 8625. Secondly, a hydrophilic coating suitable for vascular implants and finally silicone. These three materials both have a long-life, comfort surface and minimized radiation, and both of them are bio-compatible.

When we decide to market a product, several critical factors should be considered:

- The competition from other peers

- Define the ideal customer

- The unique selling proposition

- Testing

- Media campaigns

- Our aim is to design a “human mobile”, according to research. No one has invented this human mobile. Once we designed “human mobile”, there is no direct competition from other peers, but we should inform the customer what are the differences between our product and a conventional mobile phone, and what kinds of benefits can a customer get from this product. The cell phone in nowadays has many different functions, it is difficult to let customer accept our product. People may think we already have iPhone, why should we implant a mobile in our body.

- That’s why we need to define our customer, we cannot assume that all customers will accept the idea behind our product, but we can focus to a specific customer. Our product is based on convey message, GPS, WIFI and personal ID verification. Nowadays, young people are interested in new technology, and they text each other every day anytime, and are permanently connected to WIFI. So they may be curious and would like to try this new product. Moreover, they may think it is cool to implant a mobile phone into their body. The cost of the product is 689£, which is not cheap, but nowadays, the young people would like to pay for that even they cannot afford it. The iPhone is the example.

- There are two main factors in unique selling proposition:

- Benefit commitment. We need to tell the customer to know what the specific functions of our product are, and what actual benefit they can get.

- Unique. We need to emphasise our special function that our peers don’t have. This will be achieved through the advertising and news conference. Only new and unique can attract customers “eye”.

- The product must be carefully tested due to fact that it is implanted in the human body for several years. Lab test can be done to simulate the human body conditions. Also to have more prompt results and not to wait years to observe a change, more aggressive conditions can be applied during the testing. This will help define the limits of the materials and map eventual regions of the components that are more susceptible to damage than others and therefore require more frequent inspection and monitoring.

5.    As a new product, the marketing questionnaire is necessary. Is it the fastest and easiest way to know the customer would accept our product or not, and which kind of people would like to buy our product. Furthermore, we can adjust and improve our product according to the feedback from the questionnaire.

Media campaigns are necessary part of marketing; advertisement and news conferences are the best way to promote our product. But it requires a significant budget. However, the profit will excess what we paid for the marketing campaign.

As regarding the cost, according to materials we selected, and profits that a company is required to make, the cost of our product is 689£. The price includes the price of materials (the price of the materials are based on RS component website [20]), manufacturing and labour cost. Surgery fees are included. Also, as a new product, we don’t want the price of our product excess the existing successful product, like iPhones and Samsung Galaxy series. The average price of the iPhone and Samsung is £700. So the price we are offering it makes the customer think about what kind of features he can get with same amount of money.

[1] WhatIs.com, (2015). What is transistor? – Definition from WhatIs.com. [online] Available at: http://whatis.techtarget.com/definition/transistor [accessed 7 March 2017]

[2] Radio-electronics.com, (n,d). Semiconductor Materials | Types Groups Classifications | List. [online] Available at: http://www.radio-electronics.com/info/ data/semicond/semiconductor/semiconductor-materials-types-list.php [Accessed 7 March 2017]

[3] Reference, (2017). Why is silicon used to make computer chips?. [online] Available at: https://www.reference.com/history/silicon-used-make-computer-chips-d8e1def4a26f18e6 [Accessed 7 March 2017]

[4] Learn.sparkfun.com, (2009). Resistors. [online] Available at : https://learn. sparkfun.com/tutorials/resistors [Accessed 7 March 2017]

[5] Resistorguide.com, (2012). Resistor materials » Resistor Guide. [online] Available at: http://www.resistorguide.com/materials/ [Accessed 7 March 2017]

[6] Us.schott.com, (2014). SCHOTT POWERAMICâ„¢ Glass-Ceramics: A New Class of Dielectrics for High Voltage Capacitors | SCHOTT North America. [online] Available at: http://www.us.schott.com/english/news/press.html?NID=us548 [Accessed 7 March 2017]

[7] Bbc.co.uk, (2014). BBC – GCSE Bitesize: Diodes. [online] Available at: http://www.bbc.co.uk/schools/gcsebitesize/design/electronics/componentsrev6.shtml [Accessed 7 March 2017]

[8] Learnabout-electronics.org, (2017). Introduction to Diodes. [online] Available at:http://www.learnabout-electronics.org/Semiconductors/diodes_20.php[Acces-sed 7 March 2017]

[9] Hodgin, Rick. (2009). From sand to hand: How a CPU is made. [online] Geek.com. Available at: http://www.geek.com/chips/from-sand-to-hand-how-a-cpu-is-made-832492/ [Accessed 7 March 2017]

[10] Woodford, Chris. (2016). Piezoelectricity. [online] Explainthatstuff.com. Available at: http://www.explainthatstuff.com/piezoelectricity.html [Accessed 8 March 2017]

[11] Sharma, Anshul ; Kumar, Rajeev ; Vaish, Rahul ; Chauhan, Vishal S. Ferroelectrics, 04 April 2015, Vol.478(1), p.140-156

[12] Rajabi, Amir Hossein ; Jaffe, Michael ; Arinzeh, Treena Livingston. Acta Biomaterialia, 15 September 2015, Vol.24, pp.12-23

[13] Davis, S. D. ; Gibbons, D. F. ; Martin, R. L. ; Levitt, S. R. ; Smith, J. ; Harrington, R. V. Journal of Biomedical Materials Research, September 1972, Vol.6(5), pp.425-449

[14] G. Arlt, H. Dederichs and R. Herbiet, “90°-domain wall relaxation in tetragonally distorted ferroelectric ceramics,” Ferroelectrics, vol. 74, pp. 37-53, 1987.

[15] L. E. Cross, Ferroelectric Ceramics. eds. N. Setter and E. Colla, Basel, Switzerland: Birkhauser, 1993, pp. 1-85

[16] A. G. Luchaninov, A. V. Shil’nikov, L. A. Shuvalov, and I. JU. Shipkova, “The domain processes and piezoeffect in polycrystalline ferroelectrics,” Ferroelectrics, vol. 98, pp. 123-126, 1989.

[17] H. Kawai, Y. Sasaki, T. Inoue, T. Inoi, and S. Takahashi, “High-power transformer employing piezoelectric ceramics,” Jpn. J. Appl. Phys, vol. 35, pp. 5015-5017, Sept. 1996.

[18] Yang, Y. et al.”Efficient blue polymer light-emitting diodes from a series of soluble poly(paraphenylene)s.”J. Appl. Phys. 79, No. 2 (1996) pp. 934-939

[19] Gustaffson, G. at al, Nature, 357 (1992) pp. 477-479

[20] http://uk.rs-online.com/web/ [Accessed 9 March 2017]

strainoC-1

strainoC-1