Evaluating Life Cycle of Pavements

Case Study from Nevada Department of Transportation’s Perspective

Â

Nowadays increasing number of agencies and companies have started to shift to the principles of sustainability in conducting business and activities. These principles also make good business sense as we try to improve the environmental, social and economic value of a product. The transportation industry is no different and many Departments of Transportation (DOT’s) have already shifted to this by incorporating “Life Cycle Analysis” of pavements. Life cycle analysis of pavements is a comprehensive approach where economic costs of different alternatives during the life of a pavement are evaluated and the best one is chosen to be implemented. It is a complex process and varies from one DOT to another but usually there are some guidelines laid down by the Federal Highway Administration that are followed.

For our case study, we have selected the Nevada Department of Transportation, also known as NDOT. This report presents a brief overview of the various components and strategies used in pavement analysis, maintenance and rehabilitation are discussed in detail. NDOT has a defined Pavement Management System to collect data and the application of LCA for construction of pavements has already been started. The various parameters considered in LCA as well as the limitations are discussed in this report.

Keywords: Pavement, Life Cycle Analysis, NDOT, Maintenance, Rehabilitation

Pavements, like any other thing, have a definite life cycle. They are constructed by keeping a certain period of utility in mind. The continuous use of roadways often leads to their degradation in their serviceability. The rate of this deterioration is dependent on many factors both environmental and load related. Using appropriate maintenance and rehabilitation techniques at the right time also can impact the life of a pavement drastically. The life cycle of pavements can be very broadly described as

Stage 1: New Pavement

Newly constructed pavements fall into this category. They require almost no repairs while in use.

Stage 2: Minor Repairs

After some initial time, the utility of the roads begins to decrease. Some maintenance work is favored.

Stage 3: Major Repairs

After long time in service the roads become deficient structurally and continuous use of roads in this state is not recommended.

Stage 4: Complete Reconstruction

Roads in this state of disarray are not be used except under extreme circumstances and require a complete overhaul and construction of new pavements.

However, some agencies have been lagging in their effort to properly preserve their roadways. This has led to one third of the roads in United States being in poor or weak condition. Annually an estimated of 70 billion dollars to maintain the highway network in USA. This considerable sum has led people to try and manage pavements more efficiently. Constant evaluation of pavements has been adopted by many state DOT’s to try and limit pavement deterioration once it is in use.

There are two major categories for repairs of pavements in general terms are

- Maintenance

- Rehabilitation

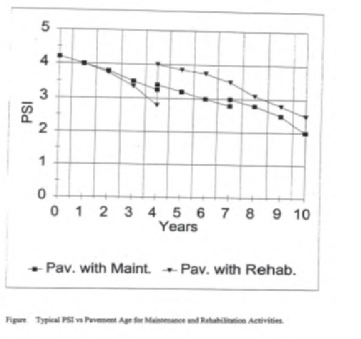

Maintenance is the process of repair of roads is done on a small scale as the pavements contain only minor faults and are fixed relatively easily. Some common maintenance techniques include fog seals and crack sealing and mainly slow down the deterioration rate of the pavements [1].

Rehabilitation is the procedure where existing portions of damaged pavements are completely redone as the damage is of significance. Rehabilitation techniques include in-place recycling and overlays and reset the whole process of deterioration [1].

The cost of either maintenance or rehabilitation of pavement is substantive and continuous to rise even today. This has lead highway agencies to use tools that can help combine economics and operations research to achieve pavements that are both cost effective without compromising their long-term properties. The most common method in use is the Life Cycle Cost Analysis or the LCCA [2]. It is a process where the value of the total project is calculated using the initial cost and discounted future costs over the life of the pavement. The components of LCCA is defined by different DOT’s independently. For this report the case of Nevada DOT is chosen and LCCA used by NDOT will be explained later.

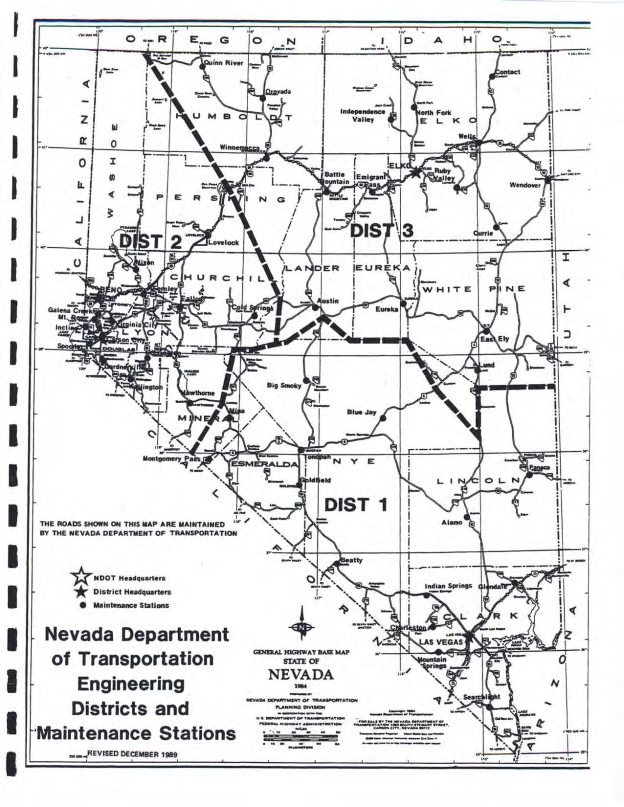

The Nevada DOT was founded in 1917 and has since built and maintained almost 5,400 miles of road. There is an additional of more than 46,000 miles of public road mostly maintained by local agencies. The roads maintained by NDOT account only for 20% of roads in Nevada but these roads account for 52% of all traffic and 82% of heavy truck traffic of the state [3]. In the fiscal years of 2013 and 2014, NDOT spend around 270 million dollars on maintenance rehabilitation repair works. As one can infer from the figures the process of maintaining the roadways is costly and therefore NDOT uses various tools that can help to minimize this cost in the long run. Some of these tools are discussed in this report.

Connecting the empirical data collected from the field and theoretical data calculated by an engineer in the lab has been one of the most difficult task in pavement engineering. Long term pavement performance has gained importance as it is a major component of any cost analyses that is conducted on the pavements. Therefore, predicting long term performance of pavements with good accuracy can provide valuable data for pavement modeling.

Field data collected from various sites can also be used to verify whether the materials possesses required qualities or the design was sufficient. This can in their turn help in altering future pavement designs to better perform in the field. This has led to the creation of a Pavement Management System by pavement engineers. Data collected from various sites in the field is collected in the PMS and stored for further analysis by engineers. This collected data can be utilized to develop and verify pavement performance models

The PMS used by NDOT was established in 1980 and is accordance with ISTEA guidelines. It monitors various pavement characteristics with time on a mile-by-mile basis for the entire NDOT system. The data collected includes cracking, rut depth, patching, surface condition, and ride with data on traffic and accidents are collected for informational purposes only.

Using the data collected from the field seven performance indicators are calculated to classify pavements into four repair categories. The performance indicators calculated are

- Ride

- Rut Depth

- Cracking

- Patching

- Bleeding

- Raveling

- Present Serviceability Index (PSI)

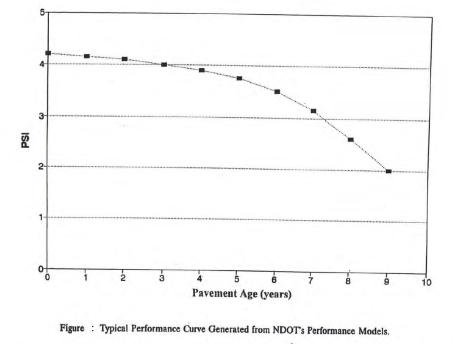

The PSI used by NDOT is calculated by the following formula

PSI = 5*e-0.0041*IRI – 1.38RD2 – 0.01(C+P)0.5

Where IRI = International Roughness Index (in/mile)

RD = Rut Depth (in)

C = Cracking Area (ft2/1000 ft2)

P = Patching Area (ft2/1000 ft2)

For the considered pavement points are assigned for the severity and extent of each of the distress indicators. The total summation of the points is used to assign the pavement into one of four repair categories which are

- Do Nothing

- Maintenance

- Overlay

- Reconstruction

For details refer to “Development of Pavement Performance, Analyses and Procedures” [4].

The PSI of pavements is kept in check by performing routine maintenance and rehabilitation activities. As explained maintenance as a process only slows down the rate of deterioration while on the other hand rehabilitation will show an initial change in PSI and may also change the rate of deterioration of pavement. Generally, one observes that the cost of maintenance of pavement tends to be lower than the cost of rehabilitation. Therefore, if one has to be cost effective there needs to be a balance between the maintenance and rehabilitation of pavements. That is using only one type of repair work will be more economically inefficient. NDOT has chosen specific repair activities to catalog in the state of Nevada based on availability of previous data. If a technique was chosen without sufficient performance data, then the model would be of limited use only.

The techniques thus used by NDOT include

Â

Maintenance Techniques: -                                                       Rehabilitation Techniques: –

Sand Seals, Chips Seals.                                                        Flexible Overlays, Roadbed                                            Modification, Mill and Overlays

Â

Sand Seals

Sand seal is the application of an asphalt emulsion being sprayed on with a layer of clean sand or fine aggregate being embedded in the emulsion either by spreading immediately or using a pneumatic tire roller. After application of the tire-roller excess particles are removed from the pavement. The sand seals are useful for improving the surface properties of pavements and can also help in filling up any fine cracks of pavement surface. In addition, the sand can also improve the skid resistant properties of the road while reducing the chances of raveling. [5].

Chip Seals

Chip seals have become one of the most used surface treatment technique for roads with less traffic. Similar to a sand seal, a chip seal is the process of spraying asphalt and applying a layer of aggregate over it. The asphalt applied could be in form of hot asphalt cement, cutback or emulsified asphalt. After the application of any of the listed types of asphalt aggregate layer is administers onto the surface, before the asphalt either cools down or the emulsion breaks so as to maximize adhesion. The aggregates in the asphalt matrix are further seated and reoriented using a pneumatic roller. Afterwards the excess aggregates are removed from the surface by use of brooming. Chip seals are used as a protection from further raveling as well as seal any small cracks that are in the pavement. Sometimes use of lightweight aggregates is justified in chip seals in cases where heavier aggregates might become a cause for windshield cracking. LWA are manufactured mainly from light minerals like shale, slate or clay and are usually more expensive and less durable than normal aggregates but these are much lighter in weight. This light weight prevents these aggregates from being able to crack windshields in the case they become projectiles. The cracking of windshields can also be prevented by use of polymer modified emulsion [5].

Flexible Overlays

Flexible overlay is a method of rehabilitation wherein on top of the old structure a new intermediate layer is constructed. The major purpose of this new layer is to both add an additional structure to the pavement and to prevent the proliferation of reflective cracks from the structure underneath. The old structure can still provide a uniform support. The design and planning of the overlay should be done keeping into consideration the expected traffic loading that the pavement will be under. As such this technique usually causes an increase in the highway profile. Care also has to be taken to prevent moisture from getting between the overlay and old structure. To prevent this the materials uses in the overlay should be tested for both moisture susceptibility and durability [6].

Roadbed Modification

Asphalt roads are also reclaimed using roadbed modification. This technique is usually applied to pavements where the PSI has fallen way below desired level. Pulverization of existing pavement is done to a depth depending upon the structure of the old pavement. The pulverization process sometimes also includes base materials sometimes if the depth of pulverization is greater than the bituminous layer. On the other hand, if the depth is lower than that of existing structure then use of cold milling can be beneficial as this will lead to minimal disturbance to the materials underneath. The materials pulverized is then mixed with cement and water, where it acts basically as aggregates. This concrete is spread out and compacted according to the design intended. Pavements with very weak or uneven foundations can benefit from this technique [7].

Mill and Overlays

The mill and overlay method is a method of rehabilitation where the top surface of the damaged pavement is removed, usually up to 2 inches. This removal is done by the use of a milling machine capable to perform the task. The removal of the top layer comprises of the milling portion of the method and usually takes around a couple of days. Afterwards a new layer of bituminous layer is constructed on top of the structure, in place of the removed surface. The surface of the milled pavement is coated with liquid asphalt that acts as a tack coat between the old structure and the new bituminous layer. The construction of the overlay can take around one to two days depending upon the width of pavement and the traffic. The asphalt overlay to be placed on pavement is usually embedded to a depth of 1½” using a paver [8].

When developing NDOT’s pavement performance model three categories of data were considered – Structural, Environmental and PMS. A list of factors from these categories was created that could possibly affect pavement performance was compiled into standard data collection form. Analyzing all the standardized data the following data sets were finally used when developing the model-

- Materials data of activity being modeled: These data include the types and percentages of asphalt binder and aggregates used in the maintenance or rehabilitation activity for which the performance model is being developed.

- Materials data of existing pavement layers: These data include the types and percentages of asphalt binder and aggregates used in the layers underlaying the maintenance or rehabilitation activity for which the performance model is being developed.

- Structural data: These data include the thickness of the various layers in the pavement structure including the thickness of the maintenance or rehabilitation activity that is being modeled. The structural number (SN) as defined by the AASHTO design guide was used to normalize the structural data among all of the pavement section. Reference 3 describes the method used to convert the layer thicknesses into SN values.

- Pavement performance data: These data include the PSI, percent cracking, and average rut depth values as obtained from the NDOT PMS data base.

- Traffic data: The equivalent single axle load (ESAL) was used as the traffic element. The average daily ESAL figures were obtained from the PMS data base and used to obtain the cumulative ESALs over the life of the maintenance or rehabilitation activity.

- Environmental data: These data include maximum and minimum temperatures, number of freeze/thaw cycles, number of wet days, and annual precipitation.

LCCA is a tool that is used by NDOT to evaluate the economic assessment of pavements when considering the entirety of its useful life. It takes into consideration the initial costs as well as maintenance and repair cost that the pavement is likely to undergo in its life. This tool can be used by pavement engineers to optimize their budget to improve the overall useful life of the pavement. Different alternatives for repairs are considered and the one with the most utility or least cost is chosen to be put forward for consideration. LCCA is made from the following steps-

- All initial treatment alternatives must be identified

- For each alternative, their analysis period as well as treatment scheme should be determined

- The price of annual and each alternatives maintenance should be computed

- The economic assessment calculated for each alternative should be compared

- The alternative with the best economic assessment should be selected based on LCCA

When performing LCCA, NDOT uses the AASHTO prescribed Present Worth method. This method is highly recommended and frequently used by state highway agencies. In this method, any future expense is converted to present value of the dollar. The present value of future expenses is the amount of money which will need to be invested at a particular compound interest rate for the total sum to be equal to the value of the future expense. The formula used in calculation is

PW = F(1/(1+i) n)

Where F = The future expense after n years

i = Discount rate

n = Number of years

Since the costs of production keeps on changing with time due to inflation and other economic factors, a discount rate is chosen to compare the cost across all time periods.

LCCA is performed on the pavement for a specific analyses period. The length of this analyses period has been calculated for various types of roads keeping important factors into consideration.

Highway Class                        Analysis Period (Years)

High Volume Urban                                          30 – 50

High Volume Rural                                           20 – 50

Low Volume Paved                                           15 – 25

Low Volume Aggregate Surface                       10 – 20

For newly constructed flexible pavements NDOT recommends an analysis period of 25-40 years while for rehabilitation they recommended a period of 20 years. This data is derived from two major conditions, (a) It represents a realistic life of asphalt mixtures and (b) one or two rehabilitation periods are included in the period.

Pavements have a defined life cycle. Regular repair work must be done during the useful life of a pavement to maintain it to a serviceable level. NDOT uses PSI as an indicator to determine the serviceability level of pavement. PSI can range from 0 to 5.0 and repair is done on a pavement when the PSI drops below an unacceptable level. NDOT uses 2.5 as the terminal level of PSI with roads having average daily traffic of more than 750.

NDOT also has placed some reality checks in place for calculating the pavement performance period. They are not considered in when in performance models because they can act as an empirical check to the values obtained from theoretical models. These checks include data such as traffic accidents, high maintenance costs, specific site failures, etc.

LCAA also include cost factors that encompass all the expenditure that is incurred by the pavement from the design phase till the end of its useful life cycle. These costs have to be properly compared for different alternatives in LCCA to arrive at the most economic pavement. These costs can include

- First Costs: These include both the expenditure for the initial construction of the pavement and the cost for the operations that occurred to facilitate the construction like surveys, designs and analyses.

- Annual Maintenance Costs: These include the expenditure that is use to maintain an optimum PSI level of the pavement so as to provide a smooth ride to the drivers.

- Road User Costs: These are the costs that are associated with driving on the road and include things like increase in travel time, accidents, change in fuel consumption by vehicle etc.

- Salvage Value: This is the value of the road at the end of its life cycle. These casts can be either positive or negative depending on the condition of the road.

1. Pavement Interactive

2. Evaluation of pavement life cycle cost analysis: Review and analysis

3. State Highway Preservation Report

4. Development of Pavement Performance, Analyses and Procedures

5.

6.http://onlinemanuals.txdot.gov/txdotmanuals/pdm/flexible_base_overlay_and_flexible_base_thickening.htm

7.

8.

9.