Flip Flops Havaianas Company Analysis

Introduction

The famous flip flops Havaianas produced by Alpargatas – a Brazilian company – had its birth in the early 60’s inspired by the Japanese sandals known as Zori[1] which are made of rice straws and stripes of fabric tissue. The rice straws were substituted by a rubber toe that is consistent and soft at the same time and brings small rice grain-inspired figures in the texture, also the fabric stripes were substituted by rubber and the initial model in white and light blue. The brand was named under the trends of Hollywood in those days, that painted Hawaii as the paradise on Earth through the movie screens, and was initially adopted by the Brazilian masses by its durability and accessible selling price. By the end of the decade, influenced by the Cold War and conflicts happening around the globe such as the Vietnam War, the youth around the world started to adopt a less materialistic lifestyle causing Havaianas to become a big trend in Brazil both by its usefulness and then by its political message.

In the 70’s due to the huge success of the brand, knock off Havaianas started to appear in the market and the response from the company came as a slogan that claimed “Protect yourself, run from the ‘bogus’, legit is only Havaianas”. The word bogus translated the Brazilian-Portuguese slang “fajuta”, which ended up being added to the dictionary as something fake in consequence of the enormous success of the propaganda (Havaianas, 2017). In the 80’s the Brazilian Federal Government issued a report including Havaianas as an utensil of basic need to be included in the basket of food staple, which is considered the crucial items for a family to survive for the period of a month including food, cleaning and hygienic products. Through the next decade, the company made several marketing efforts in order to reposition the product in the market, releasing the Floral line, the first customized series, in 1994 and 15 different colours by 1996 as a reaction from the customer’s demands, pushing the company to open new variations of the same model, now entirely in a single colour in contrast to the classic bicolor model. The turning point for Havaianas came in 1998 when they released the model Copa in celebration of the World Soccer Cup, bringing a small Brazilian Flag attached to the stripes just beside the brand’s name. The model became a symbol of Brazil and was renamed “Havaianas Brazil” being one of the most sold flip flop models in the world.

The Brazilian soccer team lost the 1998 World Cup championship but Havaianas conquered the world. In 1999 it started being officially distributed in some countries of Europe, as well as Japan and the United States and the company started to develop new models of Flip Flops for specific market niches. In 2004 it made a partnership with the Brazilian Institute of Ecological Researches to focus on solutions for the conservation of Brazilian animal species threatened of extinction. According to Havaianas’ web-site, the partnership has given so far the amount of CA$ 1.5 million to the institute. In 2010 the company started to assign new products with the brand and install branch stores in several big cities in Brazil as well as a Concept Store in an effort to bring the brand to a new level through the variety of products, a franchising model of business and new model of Supply Chain Management where inventory data are constantly updated by the store managers.

Bill-of-Materials Analysis

After understanding the history behind the company and how it became a global brand, it’s possible to choose one specific product to separate the components in a Bill-of-Material Analysis. As today the Havaianas portfolio include a large number of flip flops, sandals, espadrilles and even accessories as keyrings and beach bags; the group selected the product that represents the core of the company, the most famous globally: Havaianas Brasil.

Below there are a picture of the good and a description, both from an official website (Havaianas Store, 2015):

As it is possible to check in the description, the product is made basically of rubber. However, by studying an analysis of the production system realized by the XXXI National Meeting of Industrial Engineering in Brazil (Enegep, 2011), more details can be understood: in the manufacturing process, 40% of the materials are from waste of their own sandals, and 60% from new chemical products.

There is a video, available on YouTube, which shows a “Factory Girl” following the production process in the factory of Campina Grande, city of the state of Paraiba, Brazil (World News Network, 2008). In the beginning of the video it is possible to confirm the use of the wastes, in several colors from previous processes, to recycle and create the new collection.

In the video, the woman shows the use of the waste and the rubber, but at some point, says “secret Havaianas ingredients” to mention other components of the product, and does not provide specific information about it. Therefore, the previous analysis of the production system mentioned can help to understand what these materials can be, because is about the same factory: Alpargatas F22 – Campina Grande Unit.

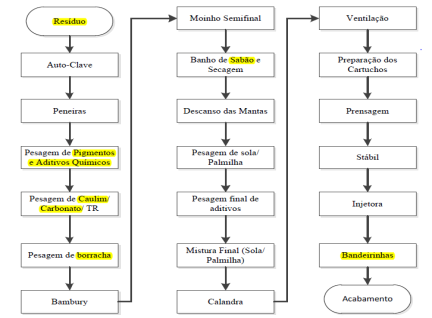

In the image below (Marinho Soares, Fernandes Barbosa, Padre de Macedo, & Lincoln Quirino Duarte, 2011) shows all the steps of the production cycle:

All the underlined words are products that serves as components, while the other boxes only contain processes, as weighing, mixture, and pressing. As the goal of the BOM is to find the components, they will be translated in the sequence as appears in the arrows, with the name in Portuguese between brackets. The first box, in the top left of the image is the Waste (Resíduo). In the fourth box there are Pigments and Chemical Additives (Pigmentos e Aditivos Químicos). Next, there are Kaolin/Carbonate (Caulim/Carbonato) and in the sixth box Rubber (Borracha). Finally, the last word underlined are Little Flags (Bandeirinhas), from Brazil, used to decorate the strap.

This way, all these products are components that are used to manufacture the flip-flops. It is interesting and important to highlight that only the Little Flags, attached to the product in the end of the cycle, are outsourced by the company. These parts are provided by one unique supplier, unfortunately undisclosed, and this fact create a dependence in the supply chain (Enegep, 2011).

The Reason for the Country of Origin for Each Component

The rubber tree is genuinely Brazilian, Serveiraira (Hevea Brasiliensis) also called Syringa and Cauchu, the tree was already known to the Native Indians long before the discovery of Brazil; In the Amazon, there are at least 11 different species of rubber tree.

Rubber was one of the main exports of the national economy in the late 1800`s and early 1900`s. It is from the rubber tree that the latex (a white liquid) is extracted and natural rubber is produced. Natural rubber is no longer an exclusive Brazilian product, when smuggled seeds have allowed other countries to explore the species. It seems only natural that one of the most popular product in Brazil is made of rubber. Inspired by the Japanese, the Havaianas became a symbol of Brazilian culture.

It represents not only the country’s lifestyle, it is also way ahead of its time, regarding the increasingly growing wave of locally produced products. Its main component is Brazilian rubber that is recycled repeatedly, creating very little waste, and is designed not only to last, but to be very comfortable. The simplicity of the Brazilian people and their laid-back attitude towards fashion, made the brand hugely popular in every demographic.

What differs Havaianas from its competitors is not only the naturally resourced recycled rubber, it`s mainly its design and marketing, that is mostly focused on the Brazilian exotic appeal. The official Havaianas design team is made of mostly Brazilian names but the brand associates itself with other designers to differentiate its product. In 2011 Havaianas partneredwith the Italian Maison Missoni, that is famous for its original prints, to create exclusive models, whose market was not only Europeans but rich Brazilians. It also partnered with the originally Brazilian jewelry company H. Stern to create a pair of golden Havaianas, the products are proving very popular with people of all ages and backgrounds. Many other fun design collabs were made that the Brazilian consumer not always knows about, like the one with the American company Dylan`s candy shop, and the hip high-end brand Charlotte Olympia.

The reason Havaianas kept its production and its natural resources sourced in Brazil is because it not only is easier to keep the whole production line in the same place, but is also good for the brand, that advertises it`s “Brazilian-ness” not only locally, but heavily oversees. It would be a diversion for the brand, that built its name on being a Brazilian company to outsource its main ingredient from anywhere else.

Current PESTLE Issues Affecting the Bill of Materials

The PESTLE analysis will allow a summary and comprehensive assessment of the set of areas that directly influence the performance of the organization and its supply chain, within the industry. For the macro environment, it is primordial analyzing trends related to variables such as macroeconomic, social, cultural, demographic, political, technological, legal, ecologists, and other factors. Understanding the scenario not only to avoid disruptions, but also to be prepared to deal with possible issues, can make the difference in the company’s pathway to the success.

Through the analysis of the Brazilian’s political context, can be observed a period of instability due to the events that happened in the last 2 years – president’s impeachment and the corruption involved – which led to the increasingly demanding laws and policies. As a result of this instability, it has made it difficult for companies to keep investing and interfering with consumer purchasing power. On the other hand, the growing liberalization of international trade and the consequent opening of trade barriers allowed the development of new economic groups.

The economic sector should consider the population growth and its product`s demand to ensure that the production will be enough to attend all the markets. Also, can be highlighted in this scenario the Brazilian currency fluctuation which makes the exchange unfavorable and increases the entry of Chinese products and leads to the decrease in exports.

Regarding social-cultural aspects, there is a growing concern with the image/aspect today. In contemporary society, people tend to be judged by their appearance, and may even be the deciding factor of choice in a job interview. This phenomenon causes people to worry about footwear more often in order to follow the fashion trends.

It is through the technological context that one can perceive the impact that technological evolution has on society and the new business opportunities that underlie it, allowing the creation of new products capable of generating new paradigms. The development of new technologies associated with the production chain aimed at minimizing production costs and maximizing the quality of the final product such as new technologies of impact absorption, raw materials processing, seams, bonding, testing, etc.

The legal scenario around Havaianas should regard the protection of Intellectual Property rights, mainly because the Havaianas is high imitated around the world (Fashion Network, 2013). Another issue that can affect Havaianas` supply chain is related to the technical standards such as IBTEC[2] and INMETRO[3], which means that the company and its suppliers need to adapt to the norms that are in constant process of change. Also, the increasingly demanding consumer protection laws can be seen by companies as opportunities to exploit, thereby enhancing their competitiveness and ensuring differentiation.

The practice of responsibility also extends to the environmental area, where Havaianas created a policy that includes all levels of the organization, allowing the implementation of various activities that seek sustainable development such as selective collection, control of waste generated, adequate transportation, actions to reduce energy and water consumption, conscientious development of materials to be used in the products, launch of ecological product lines, recycling of PVC waste in the production process itself, environmental education of all our employees and the supply chain, as well as other activities. According to Havaianas` Annual Report (Editora Contadinho, 2009), in order to support the brand’s growth cycle and increase its sustainability reputation, the environmental project was initiated and it involves their entire supply chain, sales planning, production, and logistics. Thereby, add up value to the Havaianas brand, so that the expression of embedded social and environmental responsibility in the collection of sandals, can retain and attract new customers.

The success of the company in a given business depends on its ability to perform a set of activities effectively. This set of activities, however, can change over time, either by changing competition, by the characteristics of the production process, environmental factors, among others.

Trends in Production Location

As aforementioned, 83% of the components that go into the production of a rubber slipper for Havaianas is locally and proudly sourced from where the company itself originated, Brazil. This whole production process proves to be very beneficial for the company as it allows for them to minimize a lot of costs first, by reusing wastes that result from the production of other slippers which could otherwise just be plain waste that would incur them costs without earning sales or even profit. Second, lead-time is kept at bay for the whole production process since most of the important components to produce the end-product is proximately and strategically located. Third, behavioral and cultural factors are a minimal risk to the whole supply chain as they mostly deal with people from the same country and culture. It is important to reiterate that the little flag embellishments which are outsourced directly from only one supplier is crucial to the whole supply chain as there are dangers in entrusting one important component to just one supplier.

However, although rubber which is their main raw material and its main source can be naturally found in Brazil, it has been noted that Brazil only produces 35% of the total global need. (Tereza Raquel Bastos, Globo Rural, June 2014). They would eventually have to consider creating a globalized and competitive supply chain based in Asia as the remaining 65% is now coming from that part of the world. Partnered with the fact that labor costs are exponentially cheaper in this part of the world, this is something that the company should just easily overlook. This could be a better strategy for the company as studies show that Brazilian per capita consumption of footwear is at a low 0.6 pairs while foreign markets are at 6.7 pairs. This should drive their efforts to becoming an ever more globalized brand by adopting a globalized supply chain. In the growing competitive market, companies have been pushed to become equally as competitive which in turn allows for them to assess their overall processes to ensure reduction in costs with the end goal of more revenue, this is something Havaianas should consider in their production location strategy.

Predictions for the Future

Today the demand is much greater than the Brazilian production, it only supplies 35% of the total global need. “The other 65% imported come from Indonesia, Thailand, Malaysia and Vietnam, countries that jointly seize 70% of world production. The tire industry is the main buyer, destination of about 80% of Brazilian natural rubber.” (Bastos, 2014).

Asia dominated the world supply of natural rubber, with 90% of production in the late 20`s. Major changes, however, have redistributed the production among the main competitors. Malaysia, which in 1985 accounted for 1/3 of the world production, has reduced its share due to the change in it`s production profile, which started to emphasize non-agricultural investments, so Thailand then became ranked as the world’s largest producer of natural rubber. Indonesia, has the advantages of available area and cheap labor – has maintained a relevant participation in the market since the 1980s. Other countries that have been successfully using the potential of cheap labor and availability of land for growth in this sector are India and China. The consumption of natural rubber in 2001 accounted for around 40% of the total of rubber consumed in the world.

Speaking more specifically of Brazil, according to the Rubber Tree Growers Association website the planting of rubber trees in the country “grows at an annual rate of 4.5% while domestic rubber consumption grows at a rate of 6% per year” (Durão, 2017). The same text states that Brazil’s current consumption of natural rubber “is at 340,000 tonnes (65% imported) annually”. The main concern is the prediction of doubling of the consumption of rubber in the next 10 to 15 years, not only in Brazil but throughout the world.

The rubber tree no longer gets a lot of economic support from the Brazilian government through funding for planting, which makes it hard to keep up with demand, so if this poor scenario doesn’t change in the next years the world will experience a natural rubber deficit in the house of 1,100,000 Tonnes per the IRSG (International Rubber Study Group), and Brazil will fall even further behind on the natural rubber race.

As for the future of Havaianas, it keeps looking strong. In 2013 it was announced the expansion of the product line in 40% as a new factory in Montes Carlos, Brazil was opened generating 2.500 direct jobs and 3.000 indirect jobs, the factory was set to produce 102 million pairs per year. On the official press release Mario Utah, the CEO of the company says “Alpargatas evaluated the possibility of building a factory in China, but decided to (begin) construction in Brazil (because of) the fact that Havaianas have the country in its DNA. It is extremely important for our consumers to have ‘Made in Brazil’ Stamped on the sole of our sandals. ” (Alpargatas, 2013).

Since the company uses so much of its own recycled products, is hard to see a future where the production or the gathering of the Brazilian natural rubber, becomes a problem, even if the Brazilian rubber industry slows down. And despite the rubber industry`s somber predictions, we feel positive that the expanding markets in China and the Brazilian market will work to meet the growing demand for rubber.

Bibliography

A história da seringueira: árvore que produz a borracha natural. (2014). Retrieved from http://www.pensamentoverde.com.br/meio-ambiente/historia-da-seringueira-arvore-que-produz-borracha-natural/

Alpargatas (2013). Nova fábrica da Alpargatas amplia produção de Havaianas em 40%. Retrieved from http://ri.alpargatas.com.br/arquivos/informacoes_investidores/atas_comunicados/Avisos_Comunicados/2013/Press_Release_Inauguracao_Montes_Claros.pdf

Durão, E. (n.d.). Grupo Hevea Brasil – Seringueira . Retrieved March 02, 2017, from http://www.heveabrasil.com/?page=futuro_da_seringueira.asp

Editora Contadinho. (2009). Relatório Anual 2009. Retrieved from http://ri.alpargatas.com.br/arquivos/informacoes_financeiras/relatorios_Anuais/2009/16_03_2010_Rel_Anual_2009.pdf

Factory Girl Havaianas. (2017). World News. Retrieved from https://wn.com/factory_girl_havaianas

Fashion Network. (2013). Brazilian shoes want to conquer the world. Retrievedfrom http://se.fashionnetwork.com/news/Brazilian-shoes-want-to-conquer-the-world,365833.html#.WLeyOfnyvIU

Havaianas Brasil (2017). História Havaianas | As Legítimas Desde 1962. Havaianas.com. Retrieved from http://www.havaianas.com/pt-br/historia

Havaianas Store. (2017). Flip Flops Havaianas Brasil for men | Official Havaianas® shop. Havaianas Online Store. Retrieved from http://www.havaianas-store.com/en/men/flip-flops/havaianas-brasil?options=20383%2C3755

Marinho Soares, M., Fernandes Barbosa, R., Padre de Macedo, P., & Lincoln Quirino Duarte, L. (2011). Análise do Sistema de Produção em uma Empresa Calçadista: o Caso da Alpargatas S.A (1st ed.) (pp. 7). Belo Horizonte: ENEGEP. Retrieved from http://www.abepro.org.br/biblioteca/enegep2011_tn_sto_135_855_18733.pdf

Raquel Bastos, T. (2017). Brasil produz apenas 35% da demanda nacional por borracha natural. http://revistagloborural.globo.com/. Retrieved from http://revistagloborural.globo.com/Noticias/Agricultura/noticia/2014/06/brasil-produz-apenas-35-da-demanda-nacional-por-borracha-natural.html

Wafuku. (n.d.). Traditional Japanese Footwear [Web log post]. Retrieved from https://wafuku.wordpress.com/about/

[1] Traditional Japanese footwear tends to have thong toes, like modern day flip-flops (Wafuku, n.d).

[2] IBTEC stands for Brazilian Institute of Leather, Footwear and Artifacts Technology.

[3] INMETRO stands for National Institute of Metrology, Quality and Technology.