Hard and Soft System Methodology

Introduction

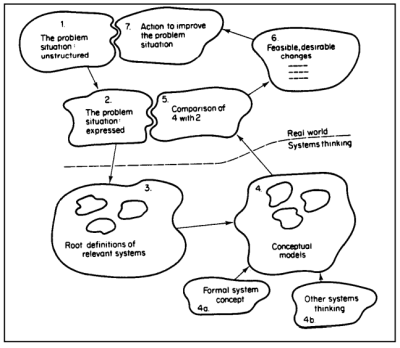

There are two systems thinking namely hard and soft which are used to solve the problems. Peter Checkland (1981) suggested that Hard system thinking which is identified in system engineering and system analysis has the starting point in structured problems and assumes that the objectives of the system are clear and stable. This system thinking has a formulated way to solve the real world problems. On the other hand, Soft system thinking which attempts to structure a debate about actions in problem solving has the start point in ‘unstructured’ problems within social activity systems.

Fixitup Toys limited is a manufacturer of toys which produces outdoor and indoor games, self-assembly models and toy soldiers. There has been some concern about their rising cost of manufacture and consideration has been given to the outsourcing of some or part of the production. The vision of the Fixitup senior management team is to optimize manufacture processing to produce the highest quality and most advanced products by using E-business conforming to the lean manufacturing principles and integrating into their established QAD Application.

In order to achieve these goals, we need to apply the principles of lean manufacturing. There are several key lean manufacturing principles including:

- Understand value in the eyes of the customer.

- Achieve perfect first-time quality.

- Continue improvement.

- Respect for humanity.

- Create pull. (Asefeso, 2011)

After Gathering information from all aspects of the company the following steps will be taken:

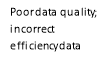

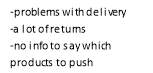

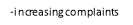

As can be seen, the Rich Picture is an unstructured way of capturing information flows, communication and human activity to represent complex problems and identify possible routes through to their solution (Berg, 2013). Avison and Fitzgerald (2003) stated that the Rich Picture is helpful since:

“1. Lack of space on the paper forces decisions on what is really important.

2. It helps people to visualize and discuss their own role in the organization.

3. It helps defining the aspects of the organization which are intended to be covered by the information system.

4. It helps showing up the worries of individuals, potential conflicts, and political issues.” (Avison & Fitzgerald, 2003)

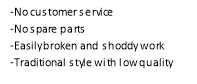

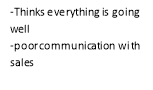

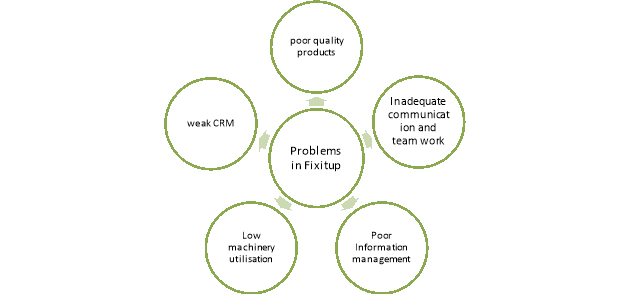

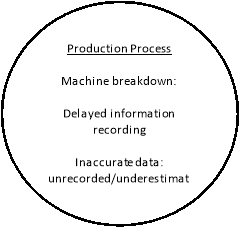

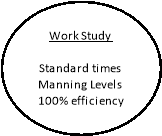

With reference to the Rich Picture, there are following problems in Fixitup.

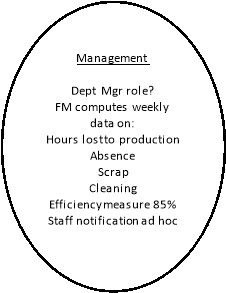

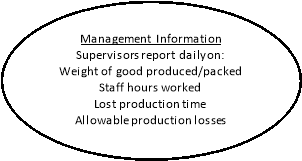

Since about 74% of customers saw the service and quality as moderate or worse, the issue of quality of products must be considered. Further, a powerful information system helps different level managements for planning, decision making, target setting and their implementations (Stephanou, 1982).Therefore, quality control system and information management system are important and they will be discussed.

Resource Resource & Investment Requirement:

Resource Resource & Investment Requirement:

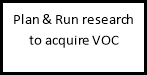

Comments: VOC was not heard because there was no effective communication between the company and its customers.

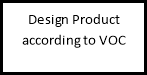

Remarks: By establishing a design department and integrating this department with the marketing department the customer feedback can be incorporated into the design.

Remarks: By establishing a design department and integrating this department with the marketing department the customer feedback can be incorporated into the design.

Comments: Lack of checklists caused the absence of the systematic process of QC hence, the chances of defects being ignored is considerably high.

Actions: The design department and the quality team will be integrated to prepare checklists according to the quality required.

Comments: Since there was no analysis of the defective products, the defects were being ignored therefore they were persistent.

Actions: Train a quality control team who will be responsible for doing analysis, recording data and providing feedback.

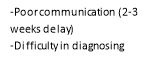

Comments: There was no coherence between the departments to respond to the quality issues.

Actions: Develop communication channels between the supervisors and the technical, procurement and design departments in order to create coherence towards quality improvement.

Comments: There was no system for controlling and monitoring the Quality Control Process.

Actions: Train the factory manager on the QC process and how he should intervene in terms of analysing quality data and controlling the system. He will seek technical advice from technical, procurement and design department for a better monitoring of the system.

Comments: Monitoring and evaluation of the information system are missing.

Actions: Helen who is responsible for Internal Affairs and George can be trained for the information system and perform monitoring the system.

Conclusion

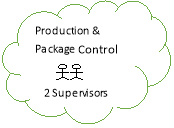

There are different problems in Fixitup which resulted in dissatisfaction of the customers. Due to having permanently relevance and also being expected to map on to an organizational boundary, the transformation from inefficient manufacturing to efficient manufacturing which has marketable products is assumed as the primary task process (Wilson and Van Haperen, 2015). Although discrimination between primary task- based and issue-based is often debatable, it seems quality control and information management systems are issue-based which help the primary task to be carried out (Waring, 1996).

The current strategy of Fixitup is to optimize manufacture processing to produce the highest quality and most advanced products by using E-business conforming to the lean manufacturing principles and integrating into their established QAD Application. After drawing the rich picture the main problems of the organization were revealed. The strategic construct which was used was ‘classification schemes’ of issues which helped to identify the differentiating characteristics necessary to improve quality control and information management systems (Verma and Boyer, 2000). Further, the system construct used for quality control was input and output; modelling of such system involves modelling of each process separately considering the connection between them (Apolloni, Howlett and Jain, 2007). In addition, the system construct used for information management system was integrated elements; in which different elements including communication, information and resources were integrated for the success of the system (Khan and Burn, 2013).

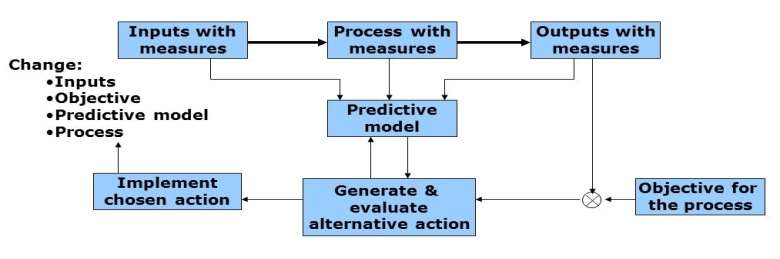

Otley and Berry (1980) argued that four conditions must be satisfied before any process can be said to be controlled. Â Â Â Â Â Â Â Â Â Â

In the existing situation there was no one responsible for monitoring the systems and consequently, there was no capacity to take corrective actions (Emmanuel, Otley and Merchant, 2013).However, in the proposed systems, George and Helen were nominated to monitor the systems. To sum up, the details of the two systems will be discussed in the following tables.

|

System name and type |

Quality Control Process; The input and output system construct. |

|

Role of information |

Due to lack of information about the requirements of customers and standard criteria set by the management, the products were just inspected for the appearance by the operators. Therefore, the application of information which was vital to improve the quality of products was missing and consequently the reputation of the factory was being worsening. |

|

Information needed to develop |

In order to use the information to improve the quality of products we need to know:

|

|

Intervention |

In order to solve the problem of quality of products the following actions are suggested:

|

|

Risks |

Even after the intervention, the following risk associated with quality of products exist:

|

|

Cost Benefit Analysis |

In order to assign a monetary value to the benefits, we need more information to predict the revenue accurately as well as intangible benefits (Mindtools.com, 2016). Having good quality products will result in increasing the loyalty of existing customers and acquisition of new customers and consequently, it will increase the revenue. In contrast, the firm may incur some costs to apply the changes. In this case, we do not have enough information about the existing departments and the expertise of employees. Assuming that none of the employees is a specialist in designing the products, we need to employ two creative designers. The rest of changes in the process can be obtained by re-engineering the departments and benefit from existing employees. In this case, there should be an increase in the employees’ wages. It seems that in long-run the total revenue will be more than total cost and the firm will have a positive profit. |

|

Resources needed, timing |

|

|

Monitoring the system |

To monitor the process we need criteria to assess the performance of the quality control process by taking information from the process (Beynon-Davies, 2013). With reference to Ouchi model (1979), the scope of controlling will be wider if sufficient knowledge of the process exists and the relevant measures of output are identified (Lind, 2014). To achieve this, George (the factory manager) who apparently has a good knowledge of the process is nominated to control the process. Further, through training and interaction with different technical departments, he must be equipped with proper checklists outlining the criteria for quality control. The role of information and communication here is undeniable. |

|

System name and type |

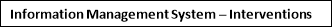

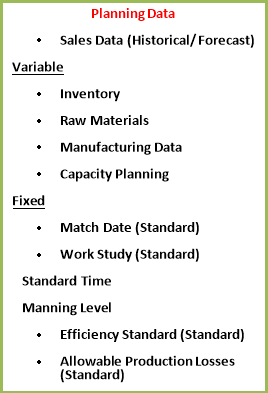

Information management system; The integrated elements system construct |

|

Role of information |

|

|

Information needed to develop |

To improve the information management system we need to know:

|

|

Intervention |

In order to solve the problem of quality of products the following actions are suggested:

|

|

Risks |

There are some risks associated with the information system (Steve, 2006) including:

|

|

Cost Benefit Analysis |

Cost benefit analysis is a process which is used to evaluate the existing system and to justify the worth of proposed information system (Issa, 2016). To measure the costs we need more information regarding database preparation, any software required, training and personal-related costs of development, and potential disruptions to operations of the business. However, the benefits of having a robust information system are: improved storage and retrieval techniques, improved resource utilization, reduced error rates and risk of incorrect processing, improved information handling which ultimately will result in improving the products and services and increasing the revenue. Since many of these aspects are intangible, we need more information to assign a monetary value to them. |

|

Resources needed, timing, |

|

|

Monitoring the system |

As it was discussed before, the process monitoring enables a firm to measure and analyze the process performance and to use data to make decisions that will improve the quality and efficiency of the process (Gasmelseid, 2011). To achieve this, Helen and George can be trained for the information system and perform monitoring the system. |

In order to improve the outcome of a consultancy project the consultancy team should obtain information as much as they can via different techniques from the organization to achieve a rich picture. With reference to Checkland’s CATWOE, the consultancy team should:

1. Know who is the victim or beneficiary of the system and how the system affects them.

2. Know the stakeholders who are involved in the situation and are responsible to implement the changes.

3. Know what are the inputs and how they are combined to provide the outputs.

4. Know the justification for the system and the relevance of the system to the world.

5. Know who has the authority to direct the system and their role in implementing the changes.

6. Know about the external environmental constraints which may restrict the changes to the system. (Belton and Stewart, 2002)

As a final point, I will give my opinion about the system approach to consulting work. Due to my previous education both for undergraduate in engineering and postgraduate in law as well as my career in shipping industry my mind-set was to approach the affairs systematically. But, it was difficult for me to know how to apply my knowledge and experience to evaluate these affairs. Now, not only for consulting work but for my personal life I know that first, we need to gather information to draw a rich picture to visualize and define different aspects of a given scenario considering that human organizations are teleological in nature. Then divide the scenario into different processes considering different system constructs. Each system should work to help achieving the strategic goals and its performance should be continuously monitored via information obtained internally or externally. To apply the factor of innovation we should carefully study each system, its boundary and environment. Then, based on nature of the projects, plan the actions while considering ethical requirements for actions. The plans then should be implemented and there should be an evaluation of the undertaken actions. To sum up, the system approach facilitates finding of problems, plan to solve the problems by innovation to achieve the strategic goals, implement the plans, and control the change process.

Bibliography

Apolloni, B., Howlett, R. and Jain, L. (2007). Knowledge-based intelligent information and engineering systems. 1st ed. Berlin: Springer, p.279.

Asefeso, A. (2011). 5s lean manufacturing (key to improving net profit). 1st ed. Lulu Com.

Avison, & Fitzgerald. (2003). Information Systems Development:Methodologies Techniques and Tools (3rd Edition ed., Vol. 3). London: McGraw-Hill.

Belton, V. and Stewart, T. (2002). Multiple criteria decision analysis. 1st ed. Boston: Kluwer Academic Publishers, p.45.

Berg, T. (2013). Understanding Iconography: A Method to Allow Rich Picture Interpretation to Improve. Doctor of Philosophy. Heriot Watt University.

Beynon-Davies, P. (2013). Business information systems. 2nd ed. London: Palgrave Macmillan, p.62.

Checkland, P. (1981). Systems thinking, systems practice. 1st ed. Chichester, Eng.: Wiley.

Davoren, J. (2016). The Three Fundamental Roles of Information Systems in Business. [online] Smallbusiness.chron.com. Available at: http://smallbusiness.chron.com/three-fundamental-roles-information-systems-business-23681.html [Accessed 7 Jan. 2017].

Emmanuel, C., Otley, D. and Merchant, K. (2013). Accounting for management control. 2nd ed. London: Springer, pp.8-9.

Gasmelseid, T. (2011). Handbook of research on hydroinformatics. 1st ed. Hershey, PA: Information Science Reference, pp.158-160.

Issa, G. (2016). The Challenges of Applying Cost Benefit Analysis to IT in Developing Countries. [online] Available at: http://citeseerx.ist.psu.edu/viewdoc/download?doi=10.1.1.378.1038&rep=rep1&type=pdf [Accessed 7 Jan. 2017].

Khan, A. and Burn, S. (2013). Project Portfolio Management in Construction Industry. 1st ed. Bloomington: Booktango.

Lind, P. (2014). Monitoring business performance. 1st ed. New York: Routledge, Taylor and Francis, p.145.

Mindtools.com. (2016). Cost-Benefit Analysis: Deciding, Quantitatively, Whether to go Ahead. [online] Available at: https://www.mindtools.com/pages/article/newTED_08.htm [Accessed 6 Jan. 2017].

Stephanou, S. (1982). The systems approach to societal problems. 1st ed. Malibu, Calif.: D. Spencer.

Steve, E. (2006). An Introduction to Information System Risk Management. 1st ed. SANS Institute, pp.2-4.

Verma, R., & Boyer, K. K. (2000). Service classification and management challenges [Electronic version]. Journal of Business Strategies, 17(1), 5-24. Retrieved [insert date], from Cornell University, School of Hospitality Administration site: http://scholarship.sha.cornell.edu/articles/59/

Waring, A. (1996). Practical systems thinking. 1st ed. London: International Thomson Business Press, p.90.

Wilson, B. and Van Haperen, K. (2015). Soft Systems Thinking, Methodology and the Management of Change. 1st ed. London: Palgrave Macmillan, p.39.