Heating Energy Requirement and Fuel Consumption Estimation

Estimation of heating energy requirement and fuel consumption in residential building by degree-day technique : a case study for Kocaeli province

Cenker Aktemur*

*Department of Mechanical Engineering, Eastern Mediterranean University, via Mersin 10, Famagusta, N.Cyprus

Abstract

Energy analysis plays an important role in the design of heating, ventilation and air conditioning (HVAC) systems at affordable and efficient cost in residential areas. Residences are in need of heating in cold weather. The mean daily outside temperature is an important guide in predicting the amount of fuel needed to heat them. The amount of fuel required to heat an area, a city or a region can be accurately estimated from the outside temperature. One of the accepted methods internationally is heating degree-day (HDD) method, which is employed for energy analysis. This paper considers the city of Kocaeli in Turkey and presents to calculate the amount of natural gas used for the annual heating for the prototype building in the case of single, double or triple-glazing, the air change rate, the number of people living in an apartment, glazing area percentage, and the fuel consumption values in accordance with these variations are obtained.

Keywords : heating degree-day, natural gas, prototype building, fuel consumption

1. Introduction

Energy is fundamental to meet many human needs, including lighting, cooking, heating and traveling. The swiftly growing world population, escalating energy demands and industrialisation of countries have resulted in high energy costs and environmental problems; therefore, studies that focus on cutting unnecessary costs have been gaining prominence. Energy consumption can be generally examined in four major sectors, namely industry, building, transportation and agriculture. In almost all countries, energy consumption in buildings constitutes a substantial part of total energy consumption. Roughly 25 – 30% of the total energy consumption in Turkey occurs in residential buildings. The energy in buildings is mainly employed in heating, domestic water preperation and cooking. Heating is the largest part of energy consumption in the buildings with 40 %. Therefore, the amount of energy required to heat buildings is a very important step and must be focused it on painstankingly.The seasonal energy requirements for the heating of buildings and the associated fuel consumption can be determined depending on the predetermined architectural design, the material characteristics of the buildings and meteorological temperature measurements. Design of conditioning systems, energy analysis in buildings, heating and cooling load calculations are mainly based on climate data. Different climate data are needed for different energy analyzes. Various energy estimation methods have been developed for buildings and climate systems. One of the methods of predicting the energy requirement for heating building in a given time of period is the degree-day (DD) method. The method assumes that the energy requirement of a building is directly proportional to the difference between the outdoor and indoor air temperatures. Heating calculations are performed for periods of time provided that the outdoor temperature is lower than a base temperature.

2. Heating degree-day method

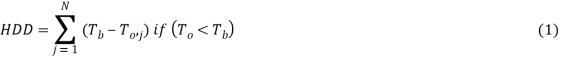

While climate data are presented in different ways for different purposes, the complexity and truthfulness of the methods developed are relied on the detailed climate data used. Accepted methods for estimating energy use of buildings in the early 1970s are developed for the need to forecast the energy usage at the macro level. One of the methods employed for the heating energy calculations is degree-day (DD) calculation method. It is the most common method since it gives very good results in energy consumption calculations for heating purposes. For several provinces it is possible to compile DD values calculated by different researchers at different base temperatures. Degree-days (DDs), the cumulative sum of the differences between the mean outdoor air temperature and base temperature, can be calculated for a specific period of time (e.g., day, week, month, or year), and they are determined only by the positive values of the temperature difference. Countries employ several techniques to calculate DD. To create a comparable and common use, European Community Statistical Office (Eurostat) proposes the following equation (1) in terms of the entire heating season for the calculation of the total number of HDD

where

where  is base temperature,

is base temperature,  is daily mean outside air temperature recorded at a meteorology station, as indicated in the following equation (2),

is daily mean outside air temperature recorded at a meteorology station, as indicated in the following equation (2),  is the number of days provided that

is the number of days provided that  in a heating season. Therefore, HDD values are calculated as

in a heating season. Therefore, HDD values are calculated as  As it can be seen from equation (2), HDD values only take on positive values.

As it can be seen from equation (2), HDD values only take on positive values.

The daily mean outdoor air temperature,  , is determined by taking the average of the measured maximum and minimum temperatures during a day.

, is determined by taking the average of the measured maximum and minimum temperatures during a day.

where  and

and  are, in turn, minimum and maximum temperatures recorded during a day [°C].

are, in turn, minimum and maximum temperatures recorded during a day [°C].

3. Practical calculations and interprations

Thermal conductivities and thicknesses of the construction materials are determined for an insulated building.  -values of outside walls, single, double and triple glazed windows, floor and roof are calculated as 0.54, 5.8, 2.7, 0.85, 032 and 0.51 W/m2K. A brief summary of physical and thermal properties of building construction materials is presented in Table 1 below.

-values of outside walls, single, double and triple glazed windows, floor and roof are calculated as 0.54, 5.8, 2.7, 0.85, 032 and 0.51 W/m2K. A brief summary of physical and thermal properties of building construction materials is presented in Table 1 below.

Table 1. Physical and thermal properties of building construction materials

|

Element |

Area |

Material |

Conductivity |

Thickness |

U-value |

|

|

Ceiling under the roof |

504 |

Insulation (fiberglass) |

0,038 |

0,07 |

0,51 |

|

|

Concrete with sand and gravel aggregate |

2,1 |

0,16 |

||||

|

Cement plaster with sand aggregate |

0,72 |

0,04 |

||||

|

Outside walls |

2208 minus |

Cement plaster with sand aggregate |

0,72 |

0,02 |

0,54 |

|

|

Brickwork |

0,84 |

0,075 |

||||

|

Insulation (Glass wool) |

0,034 |

0,05 |

||||

|

Brickwork |

0,84 |

0,075 |

||||

|

Cement plaster with sand aggregate |

0,72 |

0,02 |

||||

|

Windows |

15,20,25,30,35, |

Single glass |

5,8 |

|||

|

Double glass |

2,7 |

|||||

|

Triple glass |

0,85 |

|||||

|

Basement |

504 |

Laminate |

0,13 |

0,007 |

0,32 |

|

|

Cement mortar |

1,73 |

0,05 |

||||

|

Extrude polystren foam |

0,035 |

0,1 |

||||

|

Unreinforced concrete |

1,65 |

0,2 |

||||

.

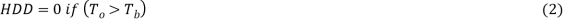

Daily means of external air temperatures over the heating season are indicated in Figure 1. The total number of heating degree-days is forecasted as 1407 at a base temperature of 15 oC for the heating season in Kocaeli by the aid of Figure 1 and equation (1).

According to TS 825 (Thermal Insulation Rules of Buildings), Turkey is divided into four climatic zones depending on DD values determined according to the average temperatures for heating. Kocaeli, the reference province located in the second climate region, was inspected in detail to determine the mean outside air temperatures in 2016. The daily mean outdoor air temperature variation, based on the records of °zmit meteorology station, is exemplified conjunction with a fitted polynomial function of the 4th order in Figure 1 below. It is possible to infer that parabolic DD alterations occur because Kocaeli transitions between Mediterranean and Black Sea climates.

Figure 1. Variation of daily outdoor air temperatures for Kocaeli.

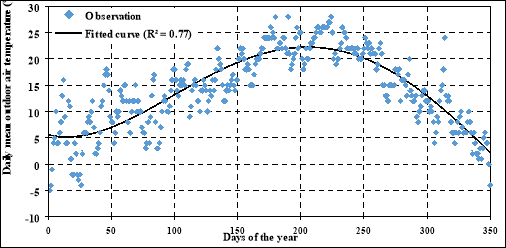

Figure 2 below are employed for determination of the starting and end of the heating season. The 278th day (22 September) and 149th day (28 May) of the year appear as the beginning and end of the heating season if  15°C is considered. It is seen that the heating season lasts 236 days within a year, which means that it encompasses approximately 55% of the heating season and it is clearly understood that there is no requirement for the heating between the 150th and 270th days of the year in Kocaeli.

15°C is considered. It is seen that the heating season lasts 236 days within a year, which means that it encompasses approximately 55% of the heating season and it is clearly understood that there is no requirement for the heating between the 150th and 270th days of the year in Kocaeli.

Figure 2. Alteration of daily HDD at a base temperature of 15 oC.

According to ASHRAE, it is necessary to properly and adequately ventilate the structure in order to meet the oxygen requirements for the maintenance of human life and to remove the air pollution that can occur for various reasons in the structure. Ventilation can be provided by the use of building systems or by natural means. Provision of natural ventilation on the buildings is more favorable than energy conservation, economy and health systems. However, in order to ventilate by means of natural methods, appropriate external air must reach the structure and this air must be absorbed into the structure through the building’s shell and ensuring adequate and proper air circulation within the structure and then the polluted air is needed to be removed from the structure.

Let us assume  (ACH) for hourly average air exchange rate,

(ACH) for hourly average air exchange rate,  = 0.5 ACH, 1.0 ACH, 1.5 ACH, and 2.0 ACH depending on the ventilation spacings. Besides, we take the glazed area percentages as 15% (352.8 m2), 20% (470.4m2), 25% (588 m2), 30% (705.6m2), 35% (823.2 m2), 40% (940.8 m2), 45% (1058.4 m2) and 50% (1176 m2) with respect to the total outside wall area. The prototype, 7-story apartment building, in which it is assumed that 40,45,50,55,60,65,70,75,80,85,90,95 or 100 people may live, is placed in °zmit (capital district of Kocaeli). The outside dimensions, widt

= 0.5 ACH, 1.0 ACH, 1.5 ACH, and 2.0 ACH depending on the ventilation spacings. Besides, we take the glazed area percentages as 15% (352.8 m2), 20% (470.4m2), 25% (588 m2), 30% (705.6m2), 35% (823.2 m2), 40% (940.8 m2), 45% (1058.4 m2) and 50% (1176 m2) with respect to the total outside wall area. The prototype, 7-story apartment building, in which it is assumed that 40,45,50,55,60,65,70,75,80,85,90,95 or 100 people may live, is placed in °zmit (capital district of Kocaeli). The outside dimensions, widt depth

depth height, of this building are considered as 28

height, of this building are considered as 28 18

18 24 m. It is tought to be 36 residences in this building. Area of roof, outside walls, and floor is 504 m2, 2208 m2 and 504 m2, respectively and total building volume is

24 m. It is tought to be 36 residences in this building. Area of roof, outside walls, and floor is 504 m2, 2208 m2 and 504 m2, respectively and total building volume is  = 12096 m3. According to these, the building’s total heat loss coefficient,

= 12096 m3. According to these, the building’s total heat loss coefficient,  (W/K), various glazing area percentage of outside walls, GAP, and

(W/K), various glazing area percentage of outside walls, GAP, and  is calculated through the following equation (4):

is calculated through the following equation (4):

because the volumetric thermal capacity of air is  = 1.2 kJ/m3K . Then, the results are tabulated in Table 2.

= 1.2 kJ/m3K . Then, the results are tabulated in Table 2.

|

Glass |

ACH |

GAP (%) |

|||||||

|

15 |

20 |

25 |

30 |

35 |

40 |

45 |

50 |

||

|

Single |

0,5 |

5560,1 |

6178,7 |

6797,3 |

7415,9 |

8034,4 |

8653,0 |

9271,6 |

9890,2 |

|

1 |

7576,1 |

8194,7 |

8813,3 |

9431,9 |

10050,4 |

10669,0 |

11287,6 |

11906,2 |

|

|

1,5 |

9592,1 |

10210,7 |

10829,3 |

11447,9 |

12066,4 |

12685,0 |

13303,6 |

13922,2 |

|

|

2 |

11608,1 |

12226,7 |

12845,3 |

13463,9 |

14082,4 |

14701,0 |

15319,6 |

15938,2 |

|

|

Double |

0,5 |

4466,4 |

4720,5 |

4974,5 |

5228,5 |

5482,5 |

5736,5 |

5990,5 |

6244,6 |

|

1 |

6482,4 |

6736,5 |

6990,5 |

7244,5 |

7498,5 |

7752,5 |

8006,5 |

8260,6 |

|

|

1,5 |

8498,4 |

8752,5 |

9006,5 |

9260,5 |

9514,5 |

9768,5 |

10022,5 |

10276,6 |

|

|

2 |

10514,4 |

10768,5 |

11022,5 |

11276,5 |

11530,5 |

11784,5 |

12038,5 |

12292,6 |

|

|

Triple |

0,5 |

3813,8 |

3850,2 |

3886,7 |

3923,1 |

3959,6 |

3996,0 |

4032,5 |

4069,0 |

|

1 |

5829,8 |

5866,2 |

5902,7 |

5939,1 |

5975,6 |

6012,0 |

6048,5 |

6085,0 |

|

|

1,5 |

7845,8 |

7882,2 |

7918,7 |

7955,1 |

7991,6 |

8028,0 |

8064,5 |

8101,0 |

|

|

2 |

9861,8 |

9898,2 |

9934,7 |

9971,1 |

10007,6 |

10044,0 |

10080,5 |

10117,0 |

|

Table 2. Building heat loss coefficient  (W/K) for various glazing type and surface area GAP, and air infiltration rate

(W/K) for various glazing type and surface area GAP, and air infiltration rate  .

.

4. Determination of heating energy requirement and fuel consumption

Seasonal heating energy requirement,  (J), for prototype building, located in Kocaeli is calculated adopting the following equation (5) in respect of HDDs and the total heat loss coefficients (

(J), for prototype building, located in Kocaeli is calculated adopting the following equation (5) in respect of HDDs and the total heat loss coefficients ( ).

).

Equation (5) is simplified as follows:

where  is energy demand (J),

is energy demand (J),  is the total heat loss coefficient of the building (W/oC),

is the total heat loss coefficient of the building (W/oC),  is the total number of DDs in a year for the heating period (°C.day) and

is the total number of DDs in a year for the heating period (°C.day) and  is design indoor and outdoor air temperature difference (°C).

is design indoor and outdoor air temperature difference (°C).

Following the determination of the total heat coefficients, the heating energy requirements are given in GJ in Table 3 below for single, double and triple glass, various GAP and I.

|

Glass |

ACH |

GAP (%) |

|||||||

|

15 |

20 |

25 |

30 |

35 |

40 |

45 |

50 |

||

|

Single |

0,5 |

675,9 |

751,1 |

826,3 |

901,5 |

976,7 |

1051,9 |

1127,1 |

1202,3 |

|

1 |

921,0 |

996,2 |

1071,4 |

1146,6 |

1221,8 |

1297,0 |

1372,2 |

1447,4 |

|

|

1,5 |

1166,1 |

1241,3 |

1316,5 |

1391,7 |

1466,9 |

1542,1 |

1617,2 |

1692,4 |

|

|

2 |

1411,1 |

1486,3 |

1561,5 |

1636,7 |

1711,9 |

1787,1 |

1862,3 |

1937,5 |

|

|

Double |

0,5 |

543,0 |

573,8 |

604,7 |

635,6 |

666,5 |

697,4 |

728,2 |

759,1 |

|

1 |

788,0 |

818,9 |

849,8 |

880,7 |

911,6 |

942,4 |

973,3 |

1004,2 |

|

|

1,5 |

1033,1 |

1064,0 |

1094,9 |

1125,8 |

1156,6 |

1187,5 |

1218,4 |

1249,3 |

|

|

2 |

1278,2 |

1309,1 |

1339,9 |

1370,8 |

1401,7 |

1432,6 |

1463,5 |

1494,3 |

|

|

Triple |

0,5 |

463,6 |

468,1 |

472,5 |

476,9 |

481,3 |

485,8 |

490,2 |

494,6 |

|

1 |

708,7 |

713,1 |

717,6 |

722,0 |

726,4 |

730,9 |

735,3 |

739,7 |

|

|

1,5 |

953,8 |

958,2 |

962,6 |

967,1 |

971,5 |

975,9 |

980,4 |

984,8 |

|

|

2 |

1198,8 |

1203,3 |

1207,7 |

1212,1 |

1216,6 |

1221,0 |

1225,4 |

1229,9 |

|

Table 3. Estimations of the heating energy requirements Q (GJ) of an apartment building

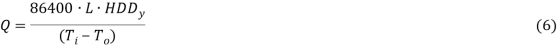

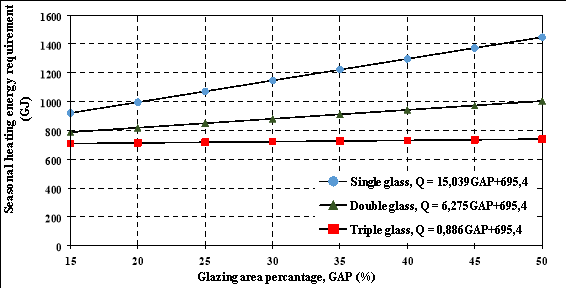

Figure 3 shows the need for seasonal heating energy in the prototype building in Kocaeli, together with the equations for both single, double and triple glasses, vs GAP. In a similar way, Figure 4 displays the seasonal heating energy requirement for the prototype building in Kocaeli for I=1.0 ACH versus different GAP.

Figure 3. Seasonal heating energy requirement for the prototype apartment building in Kocaeli for I=1.0 ACH versus different glazing area percentages.

Figure 4. Seasonal heating energy requirement for the prototype apartment building in Kocaeli for GAP=30% versus various air exchange rates.

A point to be emphasized is the number of people living in an apartment,  , of course, when this value is taken, the number of apartments in the city must be detected. In this case study, necessary calculations were made considering that the population of the city lived utterly in the apartment. Therefore, Table 4 exhibits to forecast natural gas consumption for different GAP and

, of course, when this value is taken, the number of apartments in the city must be detected. In this case study, necessary calculations were made considering that the population of the city lived utterly in the apartment. Therefore, Table 4 exhibits to forecast natural gas consumption for different GAP and  .

.

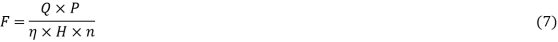

For apartment buildings in the city, the total fuel consumption in a heating season can easily be calculated by aid of the following equation (7).

where  is the total fuel consumption (m3),

is the total fuel consumption (m3), is energy demand (J),

is energy demand (J),  is population of the city,

is population of the city,  is lower heating value of natural gas (J/m3) and

is lower heating value of natural gas (J/m3) and  is the heating-system efficiencies so-called the thermal efficiency of the burning equipments.

is the heating-system efficiencies so-called the thermal efficiency of the burning equipments.

Some assumptions were made in this case study: The average population for Kocaeli city is 1,830,772, the heating value for natural gas is H = 34.526  , and the thermal efficiency is 0.88.

, and the thermal efficiency is 0.88.

Table 4. Estimation for the natural gas consumption (bcm) during the heating season in Kocaeli if all heating energy requirements are provided by natural gas.

|

No. of people living in an |

GAP |

Single glass |

Double glass |

Triple glass |

|||||||||

|

0.5 |

1.0 |

1.5 |

2.0 |

0.5 |

1.0 |

1.5 |

2.0 |

0.5 |

1.0 |

1.5 |

2.0 |

||

|

40 |

15 |

1.0 |

1,36 |

1,72 |

2,08 |

0,80 |

1,16 |

1,52 |

1,88 |

0,68 |

1,04 |

1,40 |

1,77 |

|

20 |

1,11 |

1,47 |

1,83 |

2,19 |

0,85 |

1,21 |

1,57 |

1,93 |

0,69 |

1,05 |

1,41 |

1,77 |

|

|

25 |

1,22 |

1,58 |

1,94 |

2,30 |

0,89 |

1,25 |

1,61 |

1,97 |

0,70 |

1,06 |

1,42 |

1,78 |

|

|

30 |

1,32 |

1,69 |

2,05 |

2,41 |

0,94 |

1,30 |

1,66 |

2,02 |

0,70 |

1,06 |

1,42 |

1,79 |

|

|

35 |

1,44 |

1,80 |

2,16 |

2,52 |

0,98 |

1,34 |

1,70 |

2,06 |

0,71 |

1,07 |

1,43 |

1,79 |

|

|

40 |

1,55 |

1,91 |

2,27 |

2,63 |

1,03 |

1,39 |

1,75 |

2,11 |

0,72 |

1,08 |

1,44 |

1,80 |

|

|

45 |

1,66 |

2,02 |

2,38 |

2,74 |

1,07 |

1,43 |

1,79 |

2,16 |

0,72 |

1,08 |

1,44 |

1,80 |

|

|

50 |

1,77 |

2,13 |

2,49 |

2,85 |

1,12 |

1,48 |

1,84 |

2,20 |

0,73 |

1,09 |

1,45 |

1,81 |

|

|

45 |

15 |

0,89 |

1,21 |

1,53 |

1,85 |

0,71 |

1,03 |

1,35 |

1,67 |

0,61 |

0,93 |

1,25 |

1,57 |

|

20 |

0,98 |

1,30 |

1,63 |

1,95 |

0,75 |

1,07 |

1,39 |

1,71 |

0,61 |

0,93 |

1,25 |

1,58 |

|

|

25 |

1,08 |

1,40 |

1,72 |

2,04 |

0,79 |

1,11 |

1,43 |

1,75 |

0,62 |

0,94 |

1,26 |

1,58 |

|

|

30 |

1,18 |

1,50 |

1,82 |

2,14 |

0,83 |

1,15 |

1,47 |

1,79 |

0,62 |

0,95 |

1,27 |

1,59 |

|

|

35 |

1,28 |

1,60 |

1,92 |

2,24 |

0,87 |

1,19 |

1,51 |

1,84 |

0,63 |

0,95 |

1,27 |

1,59 |

|

|

40 |

1,38 |

1,70 |

2,02 |

2,34 |

0,91 |

1,23 |

1,55 |

1,88 |

0,64 |

0,96 |

1,28 |

1,60 |

|

|

45 |

1,46 |

1,80 |

2,12 |

2,44 |

0,95 |

1,27 |

1,60 |

1,92 |

0,64 |

0,96 |

1,28 |

1,60 |

|

|

50 |

1,57 |

1,90 |

2,22 |

2,54 |

0,99 |

1,31 |

1,64 |

1,96 |

0,65 |

0,97 |

1,29 |

1,61 |

|

|

50 |

15 |

0,8 |

1,09 |

1,37 |

1,66 |

0,64 |

0,93 |

1,22 |

1,51 |

0,55 |

0,84 |

1,12 |

1,41 |

|

20 |

0,89 |

1,17 |

1,46 |

1,75 |

0,68 |

0,96 |

1,25 |

1,54 |

0,55 |

0,84 |

1,13 |

1,42 |

|

|

25 |

0,97 |

1,26 |

1,55 |

1,84 |

0,71 |

1,00 |

1,29 |

1,58 |

0,56 |

0,85 |

1,13 |

1,42 |

|

|

30 |

1,06 |

1,35 |

1,64 |

1,93 |

0,75 |

1,04 |

1,33 |

1,62 |

0,56 |

0,85 |

1,14 |

1,43 |

|

|

35 |

1,15 |

1,44 |

1,73 |

2,02 |

0,79 |

1,07 |

1,36 |

1,65 |

0,57 |

0,86 |

1,14 |

1,43 |

|

|

40 |

1,24 |

1,53 |

1,82 |

2,11 |

0,82 |

1,11 |

1,40 |

1,69 |

0,57 |

0,86 |

1,15 |

1,44 |

|

|

45 |

1,32 |

1,62 |

1,91 |

2,19 |

0,86 |

1,15 |

1,44 |

1,72 |

0,58 |

0,87 |

1,16 |

1,44 |

|

|

50 |

1,42 |

1,71 |

1,99 |

2,28 |

0,89 |

1,18 |

1,47 |

1,76 |

0,58 |

0,87 |

1,16 |

1,45 |

|

|

55 |

15 |

0,72 |

0,99 |

1,25 |

1,51 |

0,58 |

0,84 |

1,11 |

1,37 |

0,50 |

0,76 |

1,02 |

1,28 |

|

20 |

0,81 |

1,07 |

1,33 |

1,59 |

0,61 |

0,88 |

1,14 |

1,40 |

0,50 |

0,76 |

1,03 |

1,29 |

|

|

25 |

0,89 |

1,15 |

1,41 |

1,67 |

0,65 |

0,91 |

1,17 |

||||||