Interlaminar Fracture Major Failure in Polymer Composites

Composites considered new class of materials produced that are strong, not easily corroded, and have low densities. Polymer matrix composites can further be developed to get better mechanical strength and other necessary properties. Polymer Composite materials are heterogeneous in content and an-isotropic in their mechanical behavior. If compared to metallic material, fracture toughness characterization of polymer composite are new and in the process of development.

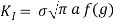

Fracture may be describe as the mechanical split of a solid owing to the function of stress. Fractures of engineering material are classify as brittle or ductile fractures [18]. Brittle fractures absorb small amount of energy, while ductile fractures absorb high amount of energy, and are generally categorized by fracture which the surface is flat. Fracture toughness is associated with the sum of the energy needed to create fracture on the surfaces. For material which is brittle, such as glass the energy needed for fracture is commonly the elemental surface energy of the material [18]. For structural alloys materials at room temperature more energy is needed for fracture because plastic deformation exist in the fracture process. The function of fracture mechanics concepts has classify and quantified the main parameters that influence structural integrity [18]. These parameters comprise the range and magnitude of the stresses applied, the shape, size, and crack orientation, fracture toughness of the material and the propagation rate of the existing cracks [18]. The fracture resistance is expressed in terms of the stress intensity factor, K and strain energy release rate is expressed in term of, G. The energy released during speedy crack propagation is an elemental material properties which not influenced by size of the part [18]. According to ASTM standard, stress intensity factor, K can be expressed as:

Â Â Â Â Â Â Â Â Â Â Â Â Â Â Â Â Â Â Â Â Â Â Â Â Â Â Â Â Â Â Â Â Â Â Â Â Â Â Â Â Â Â Â Â Â Â Â Â Â Â Â Â Â Â Â Â Â Â Â Â Â Â Â Â Â Â Â Â Â Â Â Â Â (1)

(1)

Where KI, the Mode I crucial stress intensity factor, ‘f (g)’ is the dimensionless specimen geometry and loading condition factor, and the ‘a’ is the preliminary crack length. The chosen size of the specimen must have small scale plasticity around the tip of the crack. One of the basic principles of fracture mechanics, the unstable fracture exist when the stress intensity factor, K at the crack tip achieve a critical value, KC [18]. The Higher the amount of fracture toughness, the greater the intensity of stress needed to develop crack propagation and the resistance of material also become greater to brittle fracture. Critical stress intensity factor can be determined by using a laboratory experiment, the limiting value being KIC / KIIC / KIIIC[18].

Fracture not only applied in metallic materials it can also applied brittle materials such as ceramics, glass and polymers. Polymer composite materials usually indicate a mixture of brittle and ductile failure processes. There a few fracture modes in polymer composites failure such as fiber breaking, intralaminar fracture or matrix cracking, matrix-fiber debonding, fiber pullout, interlaminar fracture or delamination, and etc [19]. In the polymer composite system, the matrix or resin absorbs energy in tearing, on the other hand the fibers break or damaged by brittle cleavage [20]. Factors that control the toughness in fiber reinforced composites are, the cracks deflection due to twisting or tilting movement near the fiber and debonding between fibers and matrix.

Interlaminar fracture major failure in polymer composites. Its development hugely weaken the stiffness of a composite structure, which can lead to the failure during service [21] and also it hugely affected the performance of laminated composite. The interlaminar performance is determined by weakness under both shear and tensile stresses. If discontinuities exist in the material the effect of the interlaminar stress to the overall performance become more significant. This delamination and their growth can be classified by the way load is applied and the strain energy release rate, G. Delamination can be categorized in Mode I “tensile”, Mode II “shear”, Mode III “tearing and shear”, or it also can be loaded in combination of between these modes. Critical strain energy release rate, GC at which the delamination started to begins to extend vary significantly depending on the mode of loading [22]. Classification of delamination resistance has attract the interest researchers, hence, it result in the development of many different test methods. According to ASTM D 5528 standard which equivalent to ISO 15024 recommends using Double Cantilever Beam (DCB) method for measuring the Mode I fracture toughness GIC of polymer composites. Next, the usage of End Notch Flexure (ENF) test for Mode II fracture toughness GIIC common method used among researchers. For Mode III fracture toughness GIIIC, Ratcliffe J [23], suggested using the Edge Crack Torsion Test (ECT). However, for Mixed-Mode bending (MMB) will follow the ASTM D6671 standard which can measure fracture toughness across a wide range of combinations of Mode I and Mode II loading.