Korean Airlines and Asiana Airlines Comparison

Question 1

Operational shall possess and control the product or service that meets the process of planning and meeting the product or customer needs. Companies should be allowed to produce at reasonable costs. They must fine-tune their production processes to focus on quality, to hold down the costs of materials and labor, and to eliminate all costs that add no value to the finished product. Making the decisions involved in the effort to attain these goals is the job of the operations manager (web-books).The operational manager shall plan the necessary solutions for planning, proceeding, and planning. I am going to discuss compare Korean Airlines (failure) and Asiana Airlines (success).

Asiana Airlines is the nation’s No.1 airline. Looking at the two airlines, I want to see what the difference is. Therefore, one can look at the parts that Korean Air needs to develop.

Corporate philosophy

First, Asiana Airlines (failure) Corporate Philosophy

As a basic philosophy, Asiana Airlines is implementing the management philosophy of “Customer Satisfaction through the Best Safety and Service” , which is “the safest, fastest, and most pleasant way to meet customers ‘ time and place . (PhilosophyCorporate, 2017)

Second, Korean Air will continue to strive to achieve the mission of ‘Excellence in Flight’. In addition, we will strengthen our competitiveness through rapid and flexible response to market changes and customer needs, and we will pursue sustainable growth and become a leader in the aviation industry. (philosophyManagement, 2017)

Various educational programs

Korean Air has organized a separate training center for specialized training in specialized job fields such as navigation, maintenance, and rooms. In addition, we are overcoming the limitations of time and place, and are activating online education to enable selective learning that meets individual needs. We are continuously developing rich contents such as acquiring business knowledge, cultivating service mind, foreign language course for global business execution

(programsVarious, 2017; programsVarious, 2017; programsVarious, 2017)

(VISIONHR, 2017)

(VISIONHR, 2017)

Asiana Airlines (failure) says human personnel is the most precious resource and gives equal opportunities for all members of the company, giving equal rewards and fair compensation. Lastly, they are trying to work as a corporate culture that allows businesses to freely communicate with other families that are free to use. Asiana Airlines is providing a systematic education with a vision of developing a global leader promoting future values and accomplishments. Through three leadership programs, education is strengthening, strengthening professional education, and strengthening service education. In addition, employees are conducting an organization culture education involving employees. Like this same series of companies, but it have slightly different operating programs and educational programs. By comparison, Asiana Airlines has a more specific and diverse variety of programs than Korean Air. Also, Asiana Airlines employees through specialized training programs to educate and train employees through continuous integration, education, and solving problems.

Finally, you can find out the special parts that Asiana Airlines have. In order to manage the performance of staff, the portion of the evaluation is similar to those of the two airlines, but Asiana Airlines performs both the coaching and interim check. It is important to objectively evaluate and assess objectives when setting goals and evaluating performance. However, it is very important to monitor and provide feedback to employees through an interim check review prior to the performance appraisal. Through this time, staff will modify and strengthen their behavior. Such a time will soon produce better results in performance appraisal. Also, Asiana Airlines has customers first through corporate philosophy. However, Korean Air takes priority over corporate culture. Of course, it is also a system for customers, but I think it is right that the customer has the philosophy to go first. I think that if Korean Air thinks about customers first and educates them, they can be better airlines and better airlines. To become an internationally recognized airline, it is a challenge not to stay in position.

Question 2

Production management, and the organization and function of which is controlled collectively. Production activities are limited to manufacturing activities, especially purchasing, manufacturing, finance and labor. The academic system, which effectively and efficiently manages the production of products and services, has long used the term “production management” because production management originated in the original manufacturing industry, or factory. However, while the service sector recently started to grow the share of traditional economic management is the name of the manufacturer as well as production operations management. There are four objectives for production management. The first is Cost. Production must be mass-produced, facilities should be used as long as possible, and maintenance costs should be low. Inventories of finished products and raw materials should be kept to a minimum, and costs for rework and waste should be minimized. The second is Quality. High quality is defined as a quality that is far higher than the competitor’s quality and is good enough to be sold despite the high price. Third is Delivery. It is refers to the ability to deliver products or services to customers at the time and place they want. Lastly is flexibility. Flexibility refers to the ability to quickly adjust production quantities in response to fluctuations in demand, and to rapidly develop new products to meet consumer needs or preferences, or to change product designs in a variety of ways.

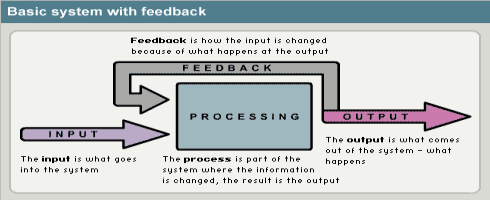

With these goals, can look at the basic system of production. A production system is systems that include all the functions required to design, produce, and services the system. There are four main parts of the system. Input is whatever goes into the system. Process is where various kinds of operation take place. Output is whatever is produced by the system. Feedback is where information about the output is used to change the input, or change the process, or start up another system. Production system is part of a comprehensive production management system that enables the planning process to be carried out according to plan, preparation of raw materials, planning, calendar scheduling, and planning for the project.

(systemsProduction, 2017)

(systemsProduction, 2017)

New service development involves everything involving product or service design, business model design and marketing. The service system develops new services by investigating markets, types, profits, and period. Test the new business model for customers, testing profitability and potential. Through this process, they can create a finished product. Another important part of the service is competitiveness. Competitiveness means that a product or service offered by a company sells better than its competitors in the market. As long as you have the competitiveness, the company can secure profits by increasing sales. Competition in the market is made by price, quality, product differentiation, elasticity (ability to cope with change) and procurement period. To compete effectively, companies need to understand the market and have enough time to explore and respond to competitors’ strategy. I am going to discuss what is wrong with the production and service systems of Tesla. I want to find a solution.

Specially, Tesla is a company that produces automobiles. Production car is a typical industries that rely on large factory and modern production equipment, granular division of labor, a large-scale homogenization of the labor force. Therefore, it is necessary to cooperate and harmonize with each other in the processes, and smooth flow of production activities and organic combination are absolutely important.

When I read this article, I thought it was the biggest problem of Tesla. “Tesla has the capacity to build 500,000 vehicles a year at its Fremont, CA plant. But last year it barely managed to build 50,000. This year, it will probably struggle to build 80-90,000. Meanwhile, it has reservations of 375,000 for its forthcoming Model 3 mass-market car, which was unveiled earlier this year and should arrive by 2017”. (file:///C:/Users/park/Downloads/Assignment%201-Operations%20management%20.pdf, 2017) The biggest problem with Tesla, why is it not natural for the company to create cars? Tesla is built a new factory to improve manufacturing capacity, but the production of existing plants is not functioning properly. The bigger problem here is that there is no system to properly manage this.Through this article, Tesla knows that the production is not working properly.This is a major drawback to growing up. To succeed in the success of new factory, must overcome factory problems.

In my opinion, the problem is the production management system that can be carried out according to plan. The problem seems to have failed and the feedback has not been answered. I think this problem arises because all the resources (manpower, equipment, materials) in the production process are inoperable. As a result, Tesla is showing this result because it is inconsistent with the input, process, output, and feedback of the production systems. Tesla has invested a huge amount of its budget on creating more industries and infrastructures. However, it is not right to start a new thing without solving the existing problems. In the end, many more losses are left behind.

Secondly, Tesla should pay attention to the service. Because they were lack sufficient services to products. The service system shall be configured so that customers can easily understand the various processes through various processes. In order to increase competitiveness, Tesla should keep the service and the process in its highest state. Must develop and develop continuously in production and service system. These developments should be accompanied by staff and customers. In conclusion, we will develop products that are practical and competitive by developing products and operating systems through various studies. This operation is helpful to the development of the company. And it will be a high satisfaction company.

In closing, through this project, I am learned more about production and service.

A production system is not simply a system of designing and generating systems, but a system that manages and manages planning, service projects, feedback and everything according to plan. And I also felt the importance of the service system.

By researching and designing products, they can create a business model, show employees and customers, and make sure that they are able to produce high-quality, profitable products through their feedback. Competitive advantage in global competition depends on the ability to provide high quality products or services at reasonable prices. In addition, faster delivery, faster introduction of new products and new services are becoming important factors in securing competitive advantage over competing companies. Technological changes also enable the production of new products or services and affect production processes. As computer and information technology evolve, new opportunities arise. If I continue to study business and become a manager or manager of a company, I think this information will surely help.

Question 3

To connect all the efficiency and profitability in order to maximize the leverage of the organization and shall operate coherently. If there’s a problem with the company, there’s some sort of operational leverage. Operating leverage operates in a system that complements systems in various enterprises.

These businesses have well-defined strategies for the future. Operating strategy ensures that business units compete with competitive advantage over time to support the desired operational structure, infrastructure, and specific set of features it consists of a decision pattern that allows you to achieve it.

And also, depending on the changing needs of the business, it can be reflected. These operations should be higher stability and potential. Also, in harmony with all other elements it must work efficiently. Operational strategies have to choose the best way to achieve the objectives and operation. The change in the operating profits is in the reasonable leverage of the company. I am going to discuss what Ryanair’s operating lever problems are and write about solutions.

The problem with Ryanair, which can be seen through this article, is that it does not care about customers. Because the company offers to already cheap price on airline tickets, they do not have to care customers. But they are missing this part. As a result, the production capacity of the company is gradually lowered affect the profit of the enterprise. The problem of constant customer management leads to companies that customers do not seek despite cheap price. Therefore, Ryanair should be first improved customer satisfaction. If so, the profit of the enterprise comes naturally. As a result, the company’s production capacity is gradually lowered, affecting the profit of the enterprise. What does they need any solution for customer care improvement? First, by default there are four key elements.

While businesses are used to identifying areas of high cost, it is equally important to examine the structure of the cost base (balance between fixed and variable, labour vs IT, operations vs corporate overhead, etc.) and trends in this structure over time. The focus on operations functions tends to be because it is easier to measure their productivity or value. Support and corporate functions are harder to measure precisely because they are essentially knowledge based functions. The key is to develop an appropriate metric for the value that they bring and the investment that is required.

Organisational restructuring is an important tool to realign the business with a new strategic direction or to improve productivity. Further analysis is necessary to determine the optimum configuration of teams (skills and responsibilities) and allocation of work (steps in a process). For example, a team may work more efficiently and provide better customer service if they complete the entire process for a particular customer. Alternatively, developing expertise in a particular part of the process may result in greater productivity and better service to customers. Your teams are the experts in what works and doesn’t work. Encourage them through a formal process and rewards to maintain a focus on this aspect of business productivity.

This lever continues to be used effectively by businesses and more rigorous approaches such as Six Sigma have gained new currency in recent years. However, with the increased availability of off the shelf technology solutions and enabling technology such as middleware and workflow, the challenge for business is how to maximise the value-add from knowledge based activities as distinct from automation of more standardised, repeatable activities. This requires new ways of thinking regarding process, skills development and training of staff in order to achieve productivity improvement across the business.

4. Knowledge management

We have referred to knowledge management several times. This is a discipline and a process which is much talked about but often relegated to the realms of information management which in some businesses is viewed as a step above records management. Every business now operates in a global, knowledge based economy. The lever to manipulate for improved performance is the ability to make knowledge an active ingredient in day to day operations. A current example is product life cycle management software. This software not only captures knowledge at every stage of a process for reuse but brings diverse functions together, e.g. Marketing and Engineering, to share information in a common format. Not only does this result in a better product but it also delivers productivity improvement in the process. (Doman Vaughan, 2017)

Ryanair’s operations manager must first understand the basic elements above. Then we need to educate our employees and develop the system. Efficient and accurate operating system causes an ongoing relationship with customers. In order to improve the productivity of the company it requires the efforts of many officers and staff. They are constantly getting new education must work to improve the operating system. Particularly the operating manager must develop better program based on the knowledge to improve production. However, this requires a rational business after identifying the organization and cost-based structure of the enterprise.

In order to improve customer satisfaction, it is essential to provide employees with products that can meet customer expectations, effectively handle customer complaints, and improve employees’ welfare and sense of unity. Finally customer satisfaction is just the quality of the products but also products with inherent to the product throughout the entire process, including planning, design, design, production, after-sales service of the product corporate culture image, providing a corporate philosophy to customers and consumers satisfaction to We must meet customer expectations more than ever, so customers should be able to increase their repurchase rates and maintain their preference.

If Ryanair understands and operates this lever, naturally, customer satisfaction is ensured up a fixed hierarchy.

In other words, customer satisfaction management is a management method that seeks to secure long-term and continuous stable profit base that is unaffected by market changes by taking customer satisfaction as the ultimate management goal, deviating from the previous management goal of increasing market share and cost reduction. (Knowledge Encyclopedia, 2017)

Doman Vaughan. (2017, 03 14). Five key levers to productivity improvement . Retrieved from Doman Vaughan: http://domanvaughan.com/productivity-improvement.html

file:///C:/Users/park/Downloads/Assignment%201-Operations%20management%20.pdf. (2017, 03 12). Case: The Hubris Effect? p. 4/7.

Knowledge Encyclopedia. (2017, 03 14). Customer Satisfaction Management. Retrieved from Knowledge Encyclopedia: http://terms.naver.com/entry.nhn?docId=463902&cid=42109&categoryId=42109

Philosophy, C. (2017, 03 06). Retrieved from Corporate Philosophy: http://flyasiana.com/CW/ko/common/pageContent.do?pageId=PC_0590

philosophy, M. (2017, 03 05). Management philosophy. Retrieved from KOREANAIR: https://kr.koreanair.com/korea/ko/about/who-we-are2.html

programs, V. e. (2017, 03 06). Various educational programs. Retrieved from https://kr.koreanair.com/korea/ko/about/who-we-are2.html

System, C. o. (2017, 03 06). Classification of Manufacturing (Production) System. Retrieved from http://www.mbanetbook.co.in/2010/05/pom-types-or-classification-of.html

systems, P. (2017, 03 06). Production systems. Retrieved from Production systems: http://www.bbc.co.uk/schools/gcsebitesize/design/resistantmaterials/processystemsrev1.shtml

VISION, H. (2017, 03 11). HR VISION. Retrieved from Aisana Airlines: https://recruit.flyasiana.com/

web-books. (n.d.). 11.1. Operations Management in Manufacturing. Retrieved 2 27, 2017, from web-books: http://www.web-books.com/eLibrary/NC/B0/B66/091MB66.htm