New Zealand Steel Sustainability

Allocation of resources is a central theme in economics (which is essentially a study of how resources are allocated) and is associated with economic efficiency and maximization of utility.

New Zealand’s Dairy companies are doing resource allocation and deliver an extensive variety of dairy products. Milk powders are a substantial part of the product mix, mirroring the sharp regularity of New Zealand milk production, distance from market, market access and demand flow, and New Zealand’s skill in milk powder producing.

This report highlights the New Zealand Steel Ltd. – Tangible as well (in) Tangible resources, techniques inside Supply Chain Management (SCM) has fluctuated generously. This is mostly because of new manufacturing technologies and strategies, additionally a consequence of the changing condition of the world economy.

Michael Porter’s theory of five forces, which characterizes the system for figuring techniques through five forces, must be incorporated with mechanical abilities of a firm to keep up upper hand. To make these reconciliations happen, supervisors need to comprehend IT in an all-encompassing way which will incorporate business with IT. This part addresses the part of innovation on the associations’ systems, how these five powers that Porter portrayed are affected by innovation and how directors ought to want to adapt to the changing circumstances with innovation. Keywords Porter’s five compels IT and watchman’s five constrains IT and Porter.

THE BIRTH OF NEW ZEALAND STEEL

New Zealand Steel Limited was incorporated in 1965. The long-term vision of those behind it was to build up a steel industry that would use the inexhaustible nearby raw materials. In 1966, development began on a plant at Glenbrook, 65 kilometres south east of Auckland. Business operations started in 1968, with imported nourish loop being utilized to deliver GALVSTEEL™ steel for local and Pacific Island markets. Interim, the organization had been spearheading the immediate lessening process for decreasing iron oxide (ironsand) into metallic iron. This finished in the charging in 1970 of iron and steelmaking offices to create billets for local and fare markets. Extension proceeded with the authorizing of a pipe plant in 1972 and a COLORSTEEL® prepainting line in 1982. Add up to yield as of now arrived at the midpoint of 300,000 tons a year.

AN INTEGRATED STEELWORKS FOR NEW ZEALAND

Significant investment in the 1980s saw the dispatching of constant slab-casting facilities and both hot and Cold Strip mills. By 1987, New Zealand Steel was working as a completely coordinated steelworks; delivering level steel items made exclusively from New Zealand Steel encourage stock. The current constant electrifying line was altered in 1994 to create ZINCALUME® steel, notwithstanding generally hot plunged excited items. Today, the rich ‘dark sands’ of the North Island keep on underpinning steelmaking at Glenbrook.

ASSETS

Natural Resources and Energy

The steelmaking operation at New Zealand Steel’s site at Glenbrook is a special procedure that utilizations ironsand found on the neighbourhood drift and transforms it into iron and steel – no other steelmaking operation on the planet makes steel similarly.

Ironsand

The key element of the steel making process in New Zealand is ironsand, which is found in wealth on the west bank of the North Island. These “blacksands” were initially noted by Captain James Cook, amid his first voyage of revelation in 1769. He named the range “The Desert Coast”. The capability of the ironsands was perceived by the early European pioneers who were captivated by the sands’ attractive qualities.

Ferrous Scrap

Ferrous piece squander emerging from the Mill’s different procedures is reused by remelting it in the steelmaking procedure.

Different Consumables

In the iron and steelmaking process amendment materials are added to conform the science of the liquid iron and steel. These incorporate dry ironsand, blazed lime, aluminium wire, Ferro-silicon and Ferro-manganese. In the metal covering procedure and pipe process vast volumes of zinc are connected to secure steel items amid their life. Paints are connected to sheet steel to give security and shading. In the completing procedures acids are utilized for cleaning the steel before coatings are connected. Acids and solvents are likewise utilized for different cleaning purposes in the rolling and completing procedures. Huge volumes of oil and oil are utilized all through the different procedures and especially in the moving factories, for plant grease.

Energy Resources and Recovery

Steelmaking utilizes a considerable measure of vitality and dealing with this proficiently is an essential piece of New Zealand Steel’s operation. New Zealand Steel is focused on industrially and naturally capable vitality administration and the advancement of vitality proficiency in the greater part of its operations. New Zealand Steel has found a way to advance vitality proficiency. It was an establishing individual from the national Energy Wise Companies Campaign and met targets determined in an early deliberate concurrence with the NZ Government to lessen carbon dioxide discharges.

The following are the energy assets New Zealand Steel employments:

COAL

The plant has an ability to utilize 800,000 tons of coal a year. The coal is utilized as a wellspring of carbon in the decrease procedure.

ELECTRICITY AND GAS

At full capacity the Glenbrook operation expends up to 1100 Gigawatt hours of power a year. This is around the sum that Wellington City (barring Hutt Valley) utilizes every year. The main part of this utilization is by the plant’s two iron milters which each expend up to 300 Gigawatt hours every year. Power represents 10 – 15% of the vitality use at the plant. The rest of the vitality needs are met with common gas sourced from the Taranaki gas fields. The common gas is utilized to preheat spoons for holding iron and steel and to warm the steel pieces before they are rolled. Some of the downstream completing procedures additionally utilize gas terminated heaters for warming and drying.

WASTE ENERGY RECOVERY

New Zealand Steel has built up a method for utilizing one of the by-results of the ironmaking procedure, to give an electrical vitality source. This diminishes its dependence on power obtained from the national network. Hot waste gasses are delivered by the multi-hearth heaters in the ironmaking procedure. New Zealand Steel has since the late 1970s exploited this hot waste gas to deliver vitality for the creation procedure, in what is known as a Cogeneration plant.

CO2 EMISSIONS

Steelmaking creates greenhouse gas emissions, mainly carbon dioxide, both straightforwardly when making iron and steel, and in a roundabout way using power and gas. The lion’s share of discharges (around 80 for each penny) originate from the synthetic procedure of making iron. New Zealand Steel has essentially lessened the force of its emanation profile since the 1990s and is constantly taking a gander at financially savvy methods for diminishing its vitality use and C02 outflows.

WATER – An essential Resource

At the Glenbrook Steel Mill every day around 1 million tons of water is available for use all through the steelmaking and finishing operations. Water is fundamental for two operations: the transportation of ironsand from the Waikato North Head mine to Glenbrook Mill and for the steelmaking forms at the Glenbrook Mill.

Transporting the ironsand requires around 7,000 tons of water every day. The Waikato River water is blended with the ironsand to shape slurry which is pumped to Glenbrook 18 km away through an underground pipe.

At the Glenbrook Mill water is utilized for cleaning waste gasses, delivering steam in the boilers, cooling, showering and flushing item, transport of strong squanders and general plant cleaning.

Extracting Water from the Environment

Waterway USERS

Recreational exercises on the lower Waikato River incorporate sculling, water skiing, angling, duck shooting and business angling. It is essential that New Zealand Steel’s water admission does not unfavourably impact these exercises.

Returning Water to the Environment

Without reusing the Glenbrook operation would require a gigantic 1 million tons of crisp water every day, with a comparative volume being released into adjoining conduits. In any case, of the aggregate volume of water in the steel factory’s water circuits, under 1% is released to the Waiuku Estuary every day. To accomplish most extreme water protection, water is cleaned, cooled and recycled ordinarily in each procedure. Some freshwater, be that as it may, must be added to the water circuits to keep up the required water quality.

WATER FROM IRONSAND SLURRY TRANSPORT

Around 7,000 cubic meters of water is utilized to transport the ironsand think from the Waikato North Head mine to the Glenbrook process, through an underground pipeline 18 kilometres in length. Once the slurry touches base at the Glenbrook site the ironsand focus is isolated from the water, which contains earth minerals accordingly of the turbulent transport handle.

WASTEWATER FROM MILL OPERATIONS

Wastewater created at the steel plant will contain either huge amounts of solids – for the most part iron oxides, coal tidy, slag – or chemicals. With fitting treatment 99% of the water is reused or recycled.

RESOURCE – Efficient Transport

Transporting products and individuals productively to reduce waste and emissions.

The productivity of all types of transportation has been a noteworthy thought at each phase of New Zealand Steel’s improvement – from the sourcing of crude materials, and transports for the workforce, to and from work.

Around 1.4 million tons of ironsand focus – the likeness the iron mineral utilized as a part of other steeling making procedure, is pumped 18 kilometres to the Glenbrook site every day. Electric fuelled transport lines and an electric underground slurry pipeline are utilized to transport the ironsand. The cost to introduce the underground transportation was colossal and a far costlier choice than trucking. Trucking was dismisses as a choice due to its high vitality prerequisites, and human and natural effect. A loaded truck would need to go between the Waikato North Head mine site to and from the Glenbrook site at 3 minute interims all day, every day to transport the required ironsand.

Coal is the other real element for steeling making. Furthermore, is stockpiled near the smelter territory to limit dealing with.

New Zealand Steel is a coordinated site where crude steel and completed items, including painted items, are altogether made. This is strange in the worldwide steel industry yet by its exceptionally nature wipes out broad transportation between each steel making process.

New Zealand Steel additionally works transports for driving staff to lessen single driver private transportation.

SUPPLY CHAIN STRATEGY

Historically the concentration of improvement techniques inside Supply Chain Management (SCM) has fluctuated generously. This is mostly because of new manufacturing technologies and strategies, additionally a consequence of the changing condition of the world economy.

The steel industry as a rule has particular characteristics that different it from different enterprises. For case the products have relative long life-cycles, the organizations are highly capital concentrated also, there is a worldwide overcapacity of steel. This implies minimal effort generation is, when all is said in done, an essential to end up distinctly a market winner and organizations can’t depend on expanded costs to guarantee their productivity (Standard and Poor’s 2007). The steel industry, particularly, is very specific and in this way ought not consent to the techniques to utilized all around, where volumes and economies of scale are the focal point of consideration today (Nyquist O. 1998). This makes an examination of SCM-procedures in organizations particularly interesting.

Steel companies have been characterized as organizations producing steel, from steelworks to processed steel. Thus, excluding the mining business (raw materials) and the designing business (modular production). The last stage included here envelops final activities, for example, cutting, bending and so on. This is frequently done by an external part, referred to as Steel Service Centers(SSC), regularly with the duty to likewise distribute the steel locally.

HUMAN RESOURCE

Creating a Safer Work Environment

At New Zealand Steel, focused on giving a safe working environment to representatives as they move towards the objective of Zero Harm. The fundamental standards under which we work are:

- Working safely is a state of business.

- Worker association is essential.

- Management is responsible for wellbeing performance.

- All wounds can be prevented.

- Preparing representatives to work securely is essential.

- Every working presentation can be safeguarded.

Each new worker undertakes thorough security acceptance, and each worker has a month to month wellbeing meeting and access to choose security delegates. They have 45 prepared Health and Safety agents who are a dynamic and enthusiastic resource.

Watching Out For Potential Hazards

Inspecting is a basic piece of our wellbeing administration logic. Its point is to help recognize, limit as well as control or take out potential working environment perils or perilous practices. The whole workforce is included in wellbeing evaluating and 95% of representatives complete no less than one security review each month. Around 400 reviews occur every week, a pledge of thousands of hours to safe work practices and conditions.

Mutual Care and Respect

The excursion towards Health and Safety excellence places commitments on both the organization and our representatives, with a necessity on both sides to show care and regard.

Individuals are required to exhibit tend to themselves and their associates as they approach their work in a sheltered way. The organization gives methods and preparing that, together with safe work conduct, can empower every worker to come back to his or her family, companions and group unharmed toward the day’s end.

Dangers will dependably exist in the working environment and individuals need to regard the earth they are in. This implies setting aside opportunity to arrange work, keeping up a mindful readiness to what is happening, and being sufficiently unassuming to recognize not having all the data (and along these lines being mindful to employment wellbeing directions).

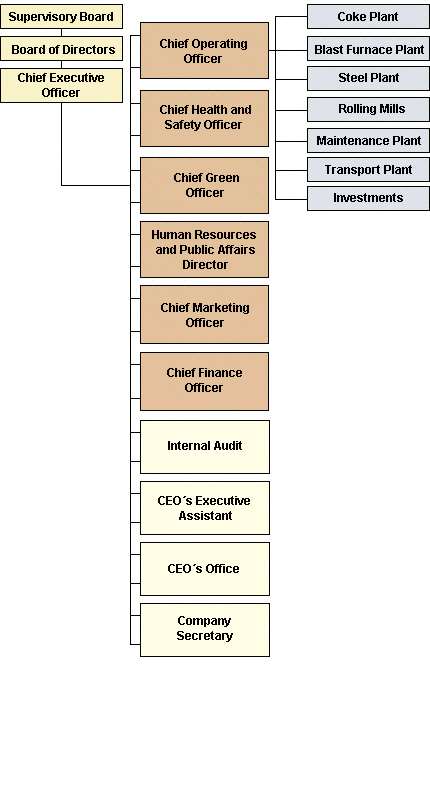

ORGANISATIONAL STRUCTURE

The whole structure of the association of Steel can be extensively divided into 3 levels, each level having separate roles and responsibilities. These 3 levels are top management, senior management and the middle management. Each of these lower levels is responsible to play out its capacities and accordingly answer to the following larger amount in the organization on an occasional basis. Overall we can state that the organization has a flat structure, starting from the top management to the lowest level of management. The Upper Management of the organization has assignment like the Managing Director of the whole organization and the Group Executive officer. The Senior Management has the various Vice Presidents of the distinctive offices which come straightforwardly under the Managing Director. Under the Vice Presidents we have the Chiefs of the various functions who organize the exercises of its capacity alongside the other departments. There can be more than one boss in an office relying on the quantity of line of the items. This is found in the Long Products Departments. The Chiefs are also accompanied by the Heads in a portion of the divisions. Under these Chiefs and Heads, we have the different Sectional Heads who are the Unit Leaders, the Managers or the Officers. This structure is common in the whole association on a national scale. In the Finance and Accounts Department, the capacities are handled by the Head of Marketing and Finance. At that point, there are the different Manager Accounts who handle the distinctive parts of the office. Under these Managers are the officers who complete the genuine bookkeeping work of the division.

SPECIAL STRATEGY OF COMPANY

The organization would likewise take an alternative of raw material, basically coal that would deliver funds. It would likewise hope to renegotiate freight contracts as a major aspect of the arrangement to shave $50m from its expenses. New Zealand management need to work through the usage of that arrangement which they will throughout the following three months or somewhere in the vicinity, so we will see a few changes in work rehearses and in expenses on the site. The current acquisition of Pacific Steel would give some “noteworthy change in the financial matters of our New Zealand operation. While the cost of coal and iron metal, used to make steel, have additionally fallen, the more quick decrease in steel costs had made utilizing iron metal and coal from somewhere else more focused than proceeding with its Australian and New Zealand mining operations. BlueScope Steel’s New Zealand Steel operations incorporate the Waikato North Head press sand mine, where 1.2 million tons are mined every year from a 150m ton ironsand store. The ironsand is sent by means of 18 kilometre underground pipe to the Glenbrook Mill site, only south of Auckland. BlueScope Steel said it expected to make $50 million in investment funds from its New Zealand operations and an aggregate of $219m from its business by 2017. The consequences of the audit are expected to be declared at its AGM in November.

The organization additionally said it has consented to offer its 28 for each penny partake in New Zealand’s McDonald’s Lime Ltd to Graymont Ltd for $41m “and perceive a $36m pre-impose benefit”. The arrangement is relied upon to be finished in October once the statutory survey time period ends.

INFORMATION SOURCE

New Zealand Steel perceives that any individual data is essential to you, and that you ought to have a privilege to control the utilization and scattering of that data. Data gathered by New Zealand Steel might be revealed as per the terms of this Privacy Policy.

Utilize and Disclosure

New Zealand Steel won’t utilize , and will utilize sensible attempts to keep the utilization or disclosure of, data gave by a client to the Site for a reason other than the main role of gathering (an ‘auxiliary reason’), but to the degree:

- that the auxiliary object is identified with the basic role of gathering and that you could sensibly anticipate that New Zealand Steel will utilize or unveil the data for the optional reason (for instance, the arrangement of your data to a provider of New Zealand Steel items where you have asked for such an item to be provided, or to our innovation suppliers for reasons of client administration, database upkeep and other comparable purposes);

- that you have agreed to the utilization of the data for the optional reason;

- that data gave by you, including data identifying with exchanges, may show up in total frame with the end goal of giving factual data inside New Zealand Steel or to outsiders. This data won’t distinguish you;

Fundamental with a specific end goal to authorize any of the terms of an assertion amongst you and New Zealand Steel;

- that New Zealand Steel has motivation to speculate that unlawful movement has been, is being or might be occupied with, and utilizes or reveals the individual data as a vital piece of its examination of the matter or in announcing its worries to significant people or specialists

- required or particularly approved by law;

- given in co-operation any administrative specialist

Access and Correction

Where New Zealand Steel gathers data from you, give you access to your data to the degree that can sensibly do as such but to the degree that:

- the demand for get to is pointless or vexatious;

- giving access would unreasonably affect the protection of others or would disregard this Privacy Policy as it identifies with others;

- the data identifies with existing lawful debate determination procedures amongst you and New Zealand Steel, and the data would not be available by the procedure of disclosure in those procedures; or

- Giving access would uncover the goals of New Zealand Steel in connection to arrangements with you so as to partiality those transactions.

New Products

ZINCALUME®

In New Zealand, where the overall winds convey destructive salt-loaded air numerous kilometres inland, ZINCALUME® offers the main line of defence.

As its name proposes it is a zinc/aluminium combination covered steel that gives fundamentally longer administration life than an aroused covering. The materials demonstration in agreement with each other, consolidating the consumption security of aluminium with the conciliatory insurance of zinc.

Flexibility is another motivation behind why the item reverberates with such a large number of. It is perfect for material, wall claddings, canals and downpipes, fences and even garden sheds.

COLORSTEEL®

COLORSTEEL® has been New Zealand’s material and cladding material of decision for quite a long time. Made extreme in light of our one of a kind condition, it’s the aftereffect of broad research and a thorough, continuous testing program.

Accessible in a scope of colours that compensation tribute to our dazzling normal environment, COLORSTEEL® is a flexible product that can be seen on homes, rural buildings and business properties appropriate around the nation.

Shifts in Market

New Zealand’s structural steel industry has been set up for over a century. Taking after years of interest in research, innovation and individuals, the industry has both the limit and the frameworks to convey huge volumes of top-quality created structural steel to building and foundation extends all through New Zealand.

Since 2007, the New Zealand industry has put significantly in new plant and innovation with development of six cutting edge workshops the nation over. This dedication by New Zealand fabricators has helped the business’ ability, effectiveness and quality. For sure, the industry is very much set to fulfil the appeal for pre-assembled auxiliary steel, which is currently like the 2007 pinnacle.

Today, basic steel’s piece of the overall industry is about half across the nation; in Christchurch, because of the material’s demonstrated seismic execution, steel has developed its share of the multi-level development market to very nearly 80%, up from for all intents and purposes nil before the Canterbury tremors.

Driven by the remaking of Christchurch and a quickly developing Auckland, New Zealand’s development industry is set to experience its busiest period in over 40 years. Neighbourhood industry – described by development, esteem, sureness and quality – has kept pace.

Recent Trends

Steel Industry Trends are not in any manner static in this industry and is an extremely alterable. The nation that is creating the greatest measure of steel may not be in the primary position in the coming years. Investigation of the Steel Industry Trends demonstrate that from the period beginning from 1910 till the year 1960, the main position as far as creating the biggest measure of steel in the entire world was caught by United States Of America. Amid this period it was watched that half of the aggregate steel creation around the world was delivered by USA. Be that as it may, the situation began to change after the nations like Japan and China went to the fore. Once more, in the current years, India and also Brazil has indicated colossal execution in the steel generation side. As per the current Steel Industry Trends, China is the biggest steel delivering country. Be that as it may, it has additionally been seen that the creation of value steel in China is low. In this way, they need to import substantial amounts of the same from the remote nations, particularly Brazil. The ascending of India as a key player on the planet steel industry situation is likewise apparent from Steel Industry Trends. Recently, the Indian Steel organization called TATA Steel has obtained the fifth biggest steel organization of the world called Corus and therefore came up from 65th to fifth position.

Steel Industry Trends likewise show that a cutting back in the steel business is a typical wonder all around the world. This wonder has emerged because of the way that this industry has moved from it’s before position of being a work serious one to a capital escalated one. The current pattern of M&A has upgraded its pace.

Steel Industry Trends if there should be an occurrence of costs have likewise demonstrated high rate of development and the principle calculate acting behind it is overabundance interest for steel produced by the development, vehicle and framework ventures. This expansion in the cost of steel can be seen along every one of the classes. The distinctive classifications of steel are Hot and also Cold Rolled Coil of steel, Hot moved plate of steel and pole made up of steel wire. The cost of medium steel sort has expanded from US $ 666 to US $ 815 between May 2006 and May 2007.

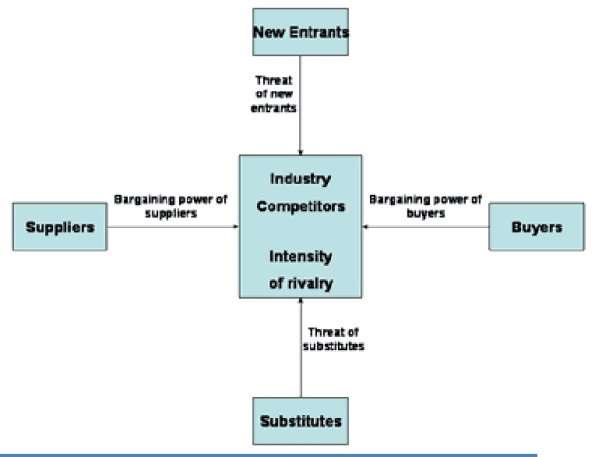

PORTER’S FIVE FORCES

An industry is a group of firms that market products which are close substitutes for each other (e.g. the auto business, the travel business). A few enterprises are more beneficial than others. Why? The appropriate response lies in understanding the elements of focused structure in an industry. The most compelling systematic model for evaluating the way of rivalry in an industry is Michael Porter’s Five Forces Model, which is depicted below:

Barriers to Entry: This force inspects how extreme the competition presently is in the marketplace, which is controlled by the quantity of existing competitors and what each can do. Rivalry competition is high when there are only a couple of organizations similarly offering an product or service, when the business is developing and when consumers can without much of a stretch change to a contenders offering for little cost. At the point when contention rivalry is high, promoting and price wars can result, which can hurt a business’ primary concern.

- Capital Requirement: Steel industry is a capital intensive business. It is estimated that to set up 1 mtpa limit of coordinated steel plant, it requires between Rs 25 bn to Rs 30 bn relying on the area of the plant and innovation utilized.

- Economies of scale: As far as the segment powers go, size of operation does make a difference. Advantages of economies of scale are inferred as lower expenses, R& D costs and better bartering power while sourcing crude materials. It might be noticed that those steel organizations, which are incorporated, have their own mines for key crude materials, for example, press mineral and coal and this ensures them for the potential risk for new participants to a huge degree.

- Government Policy: The legislature has a positive arrangement for steel producers. Be that as it may, there are sure errors required in distribution of iron mineral mines and land acquisitions. Moreover, the administrative clearances and different issues are a portion of the significant issues for the new participants.

- Product Differentiation: Steel has low barriers regarding product differentiation as it doesn’t fall into the luxury or specialty products and hence does not have any significant value distinction. Bargaining power of buyers: Unlike the FMCG or retail parts, the purchasers have a low dealing power. However, the government may control or put a roof on costs in the event that it wants to do as such. The steel organizations either offer the steel straightforwardly to the client enterprises or through their own dissemination systems. A few organizations additionally do exports.

Bargaining force of Suppliers: This force examines how much power a business’s supplier has and how much control it has over the possibility to raise its costs, which, in turn, would bring down a business’ profitability. Furthermore, it takes a gander at the quantity of providers accessible: The less there are, the more power they have. Organizations are in a superior position when there are a huge number of providers. Sources of supplier power additionally incorporate the exchanging expenses of firms in the business, the nearness of accessible substitutes, and the supply buy cost in respect to substitutes.

The bargaining power of suppliers is low for the completely coordinated steel plants as they have their own particular mines of key raw material like iron metal coal. In any case, the individuals who are non-coordinated or semi incorporated needs to rely on upon suppliers.

Bargaining power of Customers: This force looks at the force of the consumer to influence pricing and quality. Buyers have control when there aren’t a large portion of them, however lots of sellers, and also when it is anything but difficult to change starting with one business’s products or services then onto the next. Purchasing force is low when buyers buy products in little sums and the merchant’s item is altogether different from any of its rivals.

Threat of new entrants: This force looks at how simple or difficult it is for competitors to join the marketplace in the business being inspected. The simpler it is for a competitor to join the marketplace, the more prominent the danger of a business’ piece of the overall industry being exhausted. Barriers to entry incorporate total cost points of interest, access to sources of info, economies of scale and well recognized brands.

It is medium in the domestic steel industry as request still exceeds the supply. India is a net importer of steel. However, a risk from dumping of less expensive products does exist.

Threat of substitute products or services: This force concentrates how simple it is for buyer to change from a business’s product or service to that of a competitor. It takes a gander at what number of competitors there are, the means by which their costs and quality contrast with the business being inspected and the amount of a benefit those contenders are acquiring, which would figure out whether they can bring down their expenses much more. The risk of substitutes is educated by exchanging costs, both prompt and long-term, and in addition a consumer’s viewpoint to change.

It is medium to low. Despite the fact that utilization of aluminium has been raising persistently in the car and customer durable sectors, regardless it doesn’t represent any noteworthy risk to steel as the last can’t be supplanted totally and the cost differential is likewise high.

CONCLUSION

To conclude, in understanding the all the above view focuses and the current worldwide situation, we trust that the local steel industry will prone to keep up its force in the long-term. Be that as it may, the development may get influenced in short run. Investors need to concentrate on organizations that are coordinated, have economies of scale and offer premium quality products.

Be that as it may, the development may get influenced in short run. Financial specialists need to concentrate on organizations that are incorporated, have economies of scale and offer premium quality products achievement of this approach is to perceive the remarkable properties of steel as a recyclable material and to guarantee that estimations of sustainability are assumed control over the whole life cycle of an item, not only the utilization stage.

REFERENCES

http://www.nzsteel.co.nz/new-zealand-steel/the-story-of-steel/the-history-of-ironsand/

http://www.nzsteel.co.nz/sustainability/water-an-essential-resource/

http://www.nzsteel.co.nz/products/colorsteelandproducts/

http://www.businessnewsdaily.com/5446-porters-five-forces.html

https://www.equitymaster.com/detail.asp?date=12/29/2008&story=4&title=Steel-Five-force-analysis