Planning and Maintenance Problems

Plan and Maintenance

Problem 1

-

To calculate to peak operative temperature in this room in August, some assumes are made before calculation:

- The operative temperature in adjoining rooms is equal to that for the module under consideration and hence heat glow occur only through the outside window-wall;

- The window will be open during the day and close at night;

- The thermal transmittance of the window frame is equal to that of the glass;

- There are no internal blinds, therefor the solar gain to the air node is zero (Sa =0)

- According to the equation (5.42), this calculation will be divided into three parts. First, find out the mean operative temperature. Second, find out the swing in operative temperature. And find out the peak temperature in the final.

- Calculation:

Area:

External wall = 3.08m2, Internal wall = 40.88m2, Internal floor = 19.8m2

Ceiling (intermediate floor) = 19.8m2,

Glazing (include. frame) = 7.0m2

Volume of room = 55.44m3

Summed values:

Summed area  = 90.56m2

= 90.56m2

Summed U Value  = 22.1/WK-1

= 22.1/WK-1

Summed U Value  = 321.2/WK-1

= 321.2/WK-1

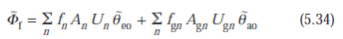

First part – Mean operative temperature:

Solar Gain through glazing (Table 5.7):

= 0.62 x 177 x 6.3

= 691.36W

Internal heat gain:

= (792 + 1280 + 1584) / 24

=152.33W

Fabric heat gain (Table 2.34(h)):

= (3.08 x 0.49 x 26.9) + (7 x 2.94 x 19.8)

= 448.08W

Total gains to environmental node:

= 691.36 + 152.33 + 448.08

= 1291.8W

Total gain to air node:

= 0 + (55.4 x 19.8)

= 1097.7W

Room ventilation conductance (Table 5.2):

=1/3 x 3 x 55.44

=55.44WK-1

Thermal response factor for the room:

= (321.2 + 55.44) / (22.1 + 55.44)

= 4.9

Room conductance correction factor;

= 3 [55.44 + (6 x 90.56)] / 22.1 + (18 X 90.56)

= 1.09

Mean operative temperature at center of room:

= [1097.7 + (1.09 x 1291.8)] / [55.44 + (1.09 x 22.1)]

= 31.51K

Second Part- Swing in operative temperature:

Swing in solar gain (Table 2.30 and Table 5.7):

= 0.44 x 6.3 x (603 – 177)

= 1180.9W

Swing in structural gain (Table 2.34(h), and given time lag factor (9.5h));

= [ (0.18 x 3.08 x 0.49) x (11.7 – 26.9) ] + [ (1 x 7 x 2.94) x (24.8 – 19.8) ]

= 98.77W

Swing in internal gain;

= [ (2 x 80) + ( 10 x 19.8) ] – 152.33

= 205.67W

Swing in ventilation heat gain:

= 55.44 x (24.8 – 19.8)

= 277.2W

Total swing in heat gain to environmental node:

= 1180.9 + 98.77 + 205.67

= 1485.3W

Total swing in heat gain to air node:

= 0 + 227.30

= 227.30W

Mean-to-peak swing in operative temperature

Room admittance factor with respect to operative temperature;

= 3 [ 55.44 + (6 x 90.56) ] / [ 321.2 + (18 x 90.56) ]

= 0.92

The swing in operative temperature at 12:30:

(at 12:30) = [ 277.2 + ( 0.92 x 1485.3) ] / [ 55.44 + (0.92 x 321.2) ]

= 4.68K

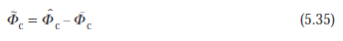

Final Part:

Peak internal operative temperature:

= 31.51 + 4.68

= 36.2°C

As the result, the temperature is too high in the office space, some issues of shading or cooling should be required to reduce the risk of overheat.

Problem 2

2a)

During project handover, the operational risk management cycle starts with the first implementation procedures by creating the risk inventory through risk identification and risk assessment.

Starting with risk identification and assessment, the better the risk assessment and the risk information gathered is structured; the more successful will be the future continuing reassessment process. Good results for risk evaluation are achieved if unit heads and risk or process experts agree on the valuation of the risk.

Then, risk mitigation and control system is carried out in view to adequately assessing the impact of an identified risk on the organization’s business, one has to consider existing controls and mitigating measures that already reduce the likelihood or severity of the risk scenario identified. A risk mitigating measure is usually a one-time measure for which an implantation date and a responsible person are defined. Risk scenario, mitigation measure, control, and loss event help to keep track of the implementation steps. These results in improved transparency, efficiency and data integrity compared to the widespread solutions that typically create problems with regard to user access rights, data integrity and confidentiality.

Followed by risk mitigation and control system is risk controlling and reporting. The goal of the risk management process is to keep identified risks in line with the risk policy and risk strategy approved by the Board of Directors and the executive team. This process could assure existing controls are actually performed and newly approved risk mitigating measures are implemented as planned.

Lastly, followed by the above steps of operational risk management processes, simple risk aggregation and consolidation methods can be introduced.

Grouping risks by categories to look for worst-case risk scenarios, consolidating risks across business units and evaluating dependencies, correlation or diversification potential between risks can be introduced already with relatively simple methods and are an important step towards an integrated risk perspective.

Based on the structured risk information gathered and the integrated perspective on all relevant risks, mitigation measures and implemented controls, the risk manager is able to produce risk reports according to the need of any type of management level.

2b)

There are a number of elements involved in the development and implantation of operational risks. They could be divided into Pre-handover activities and post-handover activities. The following responsibilities should be worked among the project sponsor, building owners, contractors and maintenance providers.

Regarding Pre-handover activities:

First, developing commissioning program which including the calibrating, testing and running of building systems, services and equipment to ensure the building is ready for use. Sometimes, the manufacturer’s representatives may be present on site to authorize the operation of services and equipment. To make sure the services and equipment have been correctly installed and functioning. Calibrating the control instruments and systems to ensure energy conservation and environment conditions are maintained.

Second, transferring of documentation to the client is involved in the development and implementation of operational risks. For example, in terms of building service, the building documentation may include: statutory authority permits and approvals, including progressive building certifier approvals. Providing plant, equipment, services and system information and schedules, including recommendations regarding lifecycle costing, “as-built†building plans and commissioning data, service maintenance requirements, operation and maintenance manuals covering design and operating parameters, service maintenance schedules, maintenance and cleaning products, tools and spare parts.

Third, the project contractors should assist the building owner or maintenance providers to determine the building maintenance requirements.

Forth, develop handover training program to familiarize the building owner and maintenance provider personnel with building equipment and systems. It is a good practice as training sessions coordination could utilize the expertise of the design and construction teams such as subcontractors. Effective training will let the building users and owners obtaining knowledge to manage the building and its fixtures, fit-outs, equipment, services and systems. The training contents may include occupational instructions and coincide with the handover of building documentation.

Regarding Post- handover activities:

First, identify outstanding defects and rectify all outstanding defects prior to final completion. If defects or omissions are identified by the building owner after final completion.

Second, monitoring maintenance and update building asset records is involved in the implantation of operational risks. Most building contracts have a defects liability period, typically for twelve months from the practical completion. Therefore, maintenance activity should be monitored and maintenance records should be continually updated to reflect any new defects and rectification works. And these records should be added into a defects report, including the details of maintenance activities undertaken.

The certificate of final completion confirms that all contractual requirements have been met, including the rectification or acceptance of all outstanding defects and attendance to all omissions.

Forth, project files and accounts are to be closed which allow easy auditing in the future. Substantial records created or received by the design and construction team must be sorted, indexed and recorded to create an auditable project trail. Care must be taken to store all financial records securely. Undertake final completion inspection to ensure satisfactory rectification of all outstanding defects.

Last but not least, update and maintain asset register and other relevant asset management systems.

Problem 3

3a)

Operating temperatures

The electrical energy produced by biomass gasification CHP plants can be consumed directly or injected into the network. The production of thermal energy can be specified at below:

High-temperature heat (steam or thermal oil, up to 200° C) applies for industries which consume heat.

Low-temperature heat (hot water at 90-95° C) applies for industries which consume heat, urban heating networks by hospitals, schools, government bodies, swimming pools, and industries linked to the wood sector that have co-products and thermal energy requirements.

Cost

The capital costs of the biomass CHP processes are much higher than fossil fuel fired CHP systems. Small-scale biomass CHP is undergoing trials in the UK. Biomass CHP offers a carbon saving potential for large sites (e.g. over 20 MWe). At these scales, biomass CHP will typically use steam turbines linked to district heating.

Environmental regulation / considerations

To apply biomass CHP, several matters should be considered. Provide a suitable supply chain for biomass fuel. The site access for large lorries delivering the fuel and storage space for the fuel. The route and mechanism to transport fuel from the store to the boiler and the plant room space around the boiler for cleaning.

Integration into the building engineering system

Building systems are usually connected to the network via a heat exchanger. Whilst there is some amount of thermal loss from the heat distribution infrastructure, the aggregation of small heat loads from individual buildings into a single large load allows the use of large scale heat technologies.

3b)

A district heating scheme comprises a network of insulated pipes used to deliver heat, in the form of hot water or steam, from the point of generation to an end user. District heating networks provide the means to transport heat efficiently. They can currently be built up to around 30km from generating plant and distribution networks can be hundreds of kilometers long. The development of the district heating scheme is benefit to the community include avoided costs of energy, through the use of surplus and wasted heat energy, and reduced investment in individual household or building heating equipment.

Problem 4

4a)

CBM is a short form Condition Based Maintenance. It is a maintenance strategy that adopted the actual condition of the asset to decide what maintenance needs to be done. It acts as a condition monitoring since it provides an instantaneous indication of a machine’s condition, ensuring critical systems maintained in top condition and spot the upcoming of plant failure. More, it helps improve the conventional maintenance regime by evaluating indicative parameters of plant condition such as temperature, vibration, oil condition, power quality.

CBM is a highly effective maintenance strategy which benefits to safety and reliability nature industries such as aircraft industry, semiconductor manufacturing, nuclear, oil and power etc. The advantages examples are stated as following:

First, it enhances fault detection in many plant items. Second, it reduces failure rates, labour time and repair budgets. Third, by carrying out the CBM, it gains the greater understanding of plant performance, and thus improves the energy efficiency and worker safety.

4b)

As mentioned in 4a), there are a lot of benefits by adopting CBM. Below are the five different CBM methods examples which would help enhance fault detection in plant items and reduce their failure rates.

First, acoustic emission monitoring which monitoring defect the naturally occurring high frequency structure borne elastic waves which are produced in materials under some form of stress. Acoustic emissions are the stress waves measuring in dB at high frequency 20kHz to 1 MHz. The instrument is commonly used to listen and measure the acoustic signals emanating from items such as pump’s bearing to define the condition with the plant during it operation. It has a good signal to noise ratio and is not affected by background noise.

Second, Vibration analysis which forecast the condition for most machines with moving parts and all rotating machinery has a degree of vibration due to difficulties in balancing the moving parts. For example, bearing degradation and misalignment, to assess plant condition to enhance fault detection and reduce failure rates.

It measured in dB at lower frequency range of 100Hz to 10KHz. When faults begin to appear in plant items, the normal vibrations begin to show signs of change. When these vibration measurements are “trended†over a period of time, the change in the plant conditions can be seen as a graphical representation. It can indicate when lubrication is required, whether the lubrication has been successful and the condition of bearings. Moreover, any misalignment, loose components and other problems that cause the machine to vibrate can be detected, giving maintenance staff the chance to intercept faults and maximise the effectiveness of these tasks and their time.

Third, application of Ultrasonic thickness testing uses complex electronic equipment to generate and detect reflections of ultrasonic vibrations from interfaces between materials. Any material that transmits mechanical vibrations can be tested.

It is the best method in terms of cost-effectiveness and the ability to detect irregularities in a metallic system. For example, it can read its thickness by simply touching the steel with the measurement head. Contact is usually assured by first removing visible corrosion scale and then applying petroleum jelly or another couplant before pressing the probe against metal. It could detect the occurrence of pitting and cracks both internally and externally resulting from corrosion, microbial and chemical contamination and general wear and tear. Therefore, it avoids the possibilities of leaking and potential failure of critical systems. More importantly, the testing is used to inspect metal to determine quality and safety without destroying or compromising its integrity.

Forth, Thermography could be used to evaluate plant condition by obtaining temperature observations of building service pant. The deviation in temperature at which particular pieces of plant operate is often indicative of plant condition. The radiation emitted from the surface of an object is a function of the object temperature with the infrared element of the radiation being measured and converted into an equivalent temperature. The thermal image is constructed from a multitude of point measurements. And the point temperature values are represented on a grey or colour scale.

Last, Lubricant and fluid analysis. Microbes can induce corrosion of steel and non-ferrous metals or they can accelerate normal electro-chemical corrosion processes. This mechanism can be occurred directly or indirectly. The analysis will reveal things like oil contamination, incorrect fill levels, as well as a breakdown or degradation of the lubricant’s composition. The procedure is performed by taking a small sample of the lubricant from the machine in question and sending it to laboratory for aassessment of the presence of the organism.

1

Order Now