Plant Layouts of Production of Isoamyl Alcohol

PLANT FACILITIES LAYOUT

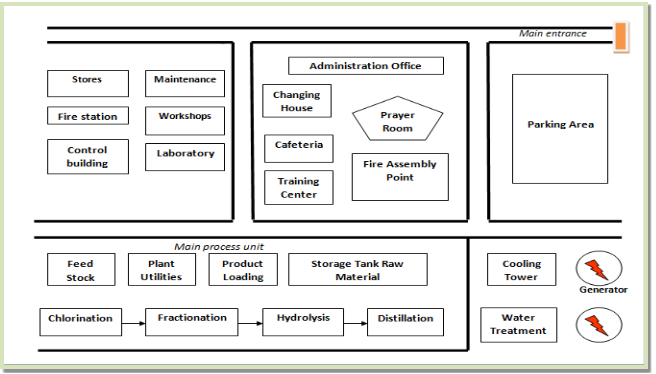

The economic construction and efficient operation of a process unit will depend on how well the plant and equipment specified on the process flow sheet is laid out. A facility is regarded as a building or a precinct. The process units and ancillary buildings should be laid out to give the most economical flow of materials and personnel around the site. Hazardous processes must be located at a safe distance from other buildings. Consideration must also be given to the future expansion of the site. A layout of a building is the map that shows the location of the building around the isoamyl alcohol plant such as car park, cafeteria, mosque, stores, workshop, laboratory and others. The most important place workers need to know is fire assembles point which a designated place where people have been told to wait after evacuating a building in the event of a fire or other emergency. A model facilities layout should be able to provide an ideal relationship between raw materials, equipment, manpower and final product at minimal cost under safe and comfortable environment. According to Riggs, “the overall objective of plant is to design a physical arrangement that most economically meets the requirement output quantity and quality”. Irregular plant layout will disturb the flow production and relationship among management and other staff member. The objective of the plant layout is:

- Provide a systematic process in the plant.

- Reduce material handling cost.

- Reduce hazard to personnel.

- Increase employee morale.

- Reduce accident in the plant.

- To provide optimum space to organize equipment and facilitate movements of goods.

Figure 1: Plant layout of isoamyl alcohol production plant

Figure 1 above shows the plant layouts of production of isoamyl alcohol and the important element in this layout. There is a power station which will be supply power to the whole plant so that there will be enough power to generate the production of plant. If the plant having a sudden loss of power source, the plant can continue to operate normal as there is generator powerful enough to supply electricity as backup source of power source as the main power station is being fix to normal condition. Thus, this will prevent loss in term of time and production rate of company including avoiding from emergency cases such as overheating of equipment as cooling process is being disturbed. There are also facilities for workers such as wide parking area, cafeteria and a room for prayer. Then, maintenance store and workshop facilities provide the spare part and maintenance of the instrument in the plant. The spare part capacity need to be control to avoid any disturb to the process line in case of emergency. The Fire assembly area is to provide the safe location if fire occur in the plant. The fire assembly area is important to check all employees safe from the incident. This location is choose by focus on a safe distance from the building and the space is large enough for all the workers in the plant to gather. Storage store refers to the controls the inflow quantity and quality of the raw material supply which are chlorine, sodium hydroxide and pentane in a high quality. This important to avoid excess amount of raw material in the plant because buying to many raw material will results tremendous space and cost to maintain them. In this section will involve the recording of raw material inflow and outflow in the plant in order to reduce the cost of operation. This storage tanks that containing hazardous materials is sited at least 70m (200 ft) from the site boundary and the main storage areas are placed between the loading and unloading facilities and the main process unit. Laboratories are placed well away from potentially hazardous processes. In order to obtain high quality of the isoamyl alcohol production, the raw material supply needs to achieve the specification level that has been set in this company. This area will running the test for production line and raw material supply. Every raw material that being supply for production area need to be passed a quality test to control the quality of the product. All the analysis equipment will be located in the laboratory. The important part in the plant, this is the production of isoamyl alcohol occur. All the instruments involve in the production of isoamyl acohol will set in this area and systematic arrangement of instrument need to have in order to have efficient production line. The isoamyl alcohol production will undergoes chlorination, fractionation, hydrolysis and distillation process. Cooling towers are sited so that, under the prevailing wind, the plume of condensate spray drifts away from the plant area and adjacent properties.