Simulation in Logistics and Supply Chain

- Introduction:

The main task of this paper is to exemine how simulation is being used in logistics and supply chain (LSC) in relation to planing and control. In order to understand how simulation is being used to analyse the supply chain performance, a literature review was critically analyse. The main focus of this reserch was to analyse the various methods being used in simulation as regard the supply chain planing and control in order to analyse the benefit and contrain of the various method (   ).

A sample of problem in SC was identify and treated with one of the methods of simulation in order to measure the efficiency and effectivenes within SC. Conclusion was drawn which compares and contras both approch to measure the weakness and streagnth in diffrent circumstancies.

- Problem Identification and Description

- Litrature Review

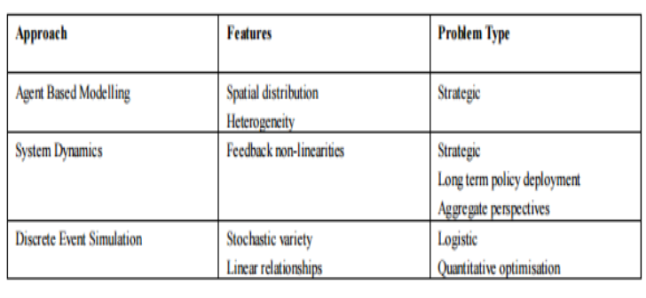

A review recently by Cid Yanez et al., (2009) Identified more comprehensive taxonomy of the different types of simulation wich ara: continuous, discrete, System Dynamics, Gaming, Agent, Artificial Intelligence, Virtual Reality etc. However, thier are quite of number of methods or techniqures used in planing accross supply chain, namely XML, Spreadsheet, Mathematical Modelling, Java, potal Software, Matlab, etc. In contrast Skiadas and Skiadas, (2009) argue that methods or techniqures like Spreadsheet, XML, Java and Genetic Algorithm were not actual simulation techniqure but rather are merely simple analysis tools and programming methods wich is categorised under Discrete Mathematical Model wich are static in nature. In the same vein Small et al., (2013) suggests that Discrete mathematical model is diffrent in nature because it try to find an optimal solution to a problem in the present rather than in the future. In view of DAVIS, EISENHARDT and BINGHAM, (2007) agrees that mathematical modelling techniqures cannot deal with dynamic and complex situiation expecially in gaining competative advantage through the supply chain network. This means that mathematical model or techniques is not considered as the best in dealing with real phenomenon. Example product demand forecasting. Conversely, Dynamic simulation modelling is regarded as poor modelling techniqures as it lacks the ability to handle too detailed LSC micro problems such as job sequencing (Longo, 2011). However as ponted out by Chopra and Mendl (2007) there are three basic supply chain simulation in planinig and control wich are: System Dynamics (SD), Discrete Event Simulation (DES), and Agent Based Modelling (ABM). Accordingly, Lorenz and Jost (2006) have identified these three basic types of simulation in supply chain planing and optimization, each problem has a particular approach being used to find optimal solution. In view of the defination provided by copra and mendl (2011) in relation to supply chain management decision making, identified two main problem namely; strategic and opertational wich can be tackled by these approch (i.e. SD, DES ABM). (    ) suggest that In order to make the right decision it is important to prepare them with appropriate planning and control.

Similarly, Arne Schuldt (2010) state that the primary supply chain function are applied in order to tackle challenges usually, each of the function is not sufficient alone to tackle the challenges instead multiple functions contributed by multiple techniques or model must be combine to supply network in order to make the right decision. For instance, Baril et al. (2016) use both approch to improve health care service delivery by reducing patient delay using DES, SD to improve patient pathways and ABM for quick implementation process. As can be seen both method can be used to achieve SC strategic and planning objectives

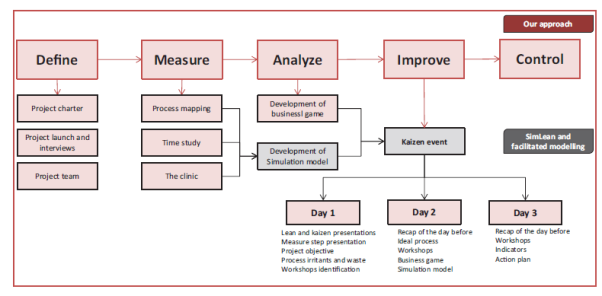

However, Lean thinking simulation and implementation has emerged in various segment of the suppy chain particularly in manufacturing and recently in the healthcare because, recent litrature has shown significant benefit such as increased patient and management throughput(  ). In view of ( ) every oranisation has similar process of simulation implemetation wich must start with define value, measure, analyse, improve and control as indicated in the following figure 1

Figure 1 Organisational Approch of Simulation

Source: (Baril et al. 2015)

- STRENGTHS AND WEAKNESSES OF THE THREE (3) APPROACHES

- System Dynamics

Despite the potential benefit and broad range of applications of SD in supply chain domains, the SD techniques is often regarded as a means suited to handle only macro SC problems and relational policy problems before implemetation (       ). Conversely, SD is regarded as a poor modelling technique but, as agued by (  ) that System Dynamics need to be complemented by micro modelling techniques in many situation, such as credible models which lies in the body domain of Descret event simulation that is strong and beneficial for analysing detailed and complex situaions. However, from its earliest to the recent reserch in SC (  ) has identified that feedback flow of information has been a core central features of SD and the techniques has been used to analyse many SC problems where studies finding suggested that SD is a continuous and syncronose procesess where operations are aggregated together rather than being as seprate or discrete entities. For This reason it has being suggests that the the SD techniques may be less effective to tackle problems where human behaviour or individul are observed. For example shoppers habit in Tesco. In the same vein, (  ) that one of the constraint of SD, is not effective to tracking movement of individual in space and location. In other word, one of the major aim of SC is targeted at individaul customer but, SD being a cyclical process may not model the movement of individual as it tend to varies from one point in time to another. For instance, the Impact of Brexit policy in the uk to Eu may have negative impact on various supply chain networks (Viner, 2016). Therefore, SD is aims only at addressing policy problems that are strategic in nature rather than tactical or operational level particularly dealing with human interaction in SC (      ). In contrast, many scholars in the field of SC claims that ABM can model detailed distinct behaviour where spatial relationships co-exist. And ABM can be used to model the behaviour of distict supply chain or distinct suppy node (       ). For example SD deals with problems like:

- Supply chain redesign

- Quality perception and Quality Control

- E-collaboration

- Impact of demand amplification on transport cost

- Cycle time compression and Performance metrics

- The effect of batching on bullwhip

- Discrete Event Simulation (DES)

Base on litrature reviews, claims that DES is very effective to handle the problem of variation in time intervals (   ) In similar vein, DES in supply chain planing and control can be used to measure relationships between entities in it strategic form. For example……………………………. (   ) argue that DES is not very effective for modelling policy in it generic level. Of course in reality SC problems under critical study ranging from planing, operations, and strategy, a more embodied discription by many leading scholar in the field of SC emphasised the need of of DES in the operational and planing level whereby the DS is more practicable in application to strategic level problems (        )

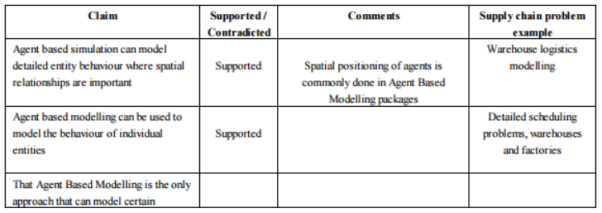

- Agent base Simulation

Agent Based Modelling ABM is an emerging method of simulation capable of application throughout the range from the strategic to operational level in the supply chain Arvitrida, Robinson and Tako, (2015) . As an emerging model, a number of views have been made for ABM. For instance, agent base model of simulation can be use to exemine distinct behaviour where spatial interconnection of relationships core exiest (       ). Similarly, agent based simulation can be used to model the behaviour of individual characteristics and it has being term as the only techniqures that can model certain features such as “agilty” to respond to ever increasing level of volitality of deman, agility in the sense of quick response to what ever situation under study (Critopher, 2011 ). ABM deals with supply chain ploblem in the following:

- Market dynamics

- Modelling control elements

- Human behaviour on bullwhip effect

- Human behaviour and trust

- Collective customer collaboration

Table 1 Agent Base Simulation Source: (    )

Table 2 Approach, Feaures and Problem Source: (    )

- Discussion and Conclusion

The review of the litrature in this paper point out the benefit and constraint. In other word, it differenciate the various method of simulation in sc perspective. It shows that the various method varies and differs in scope both in customs and in practice or reality. In particular, SD is predominantly regarded as static in nature as it involves in continuous process or vertual techniques to tackle macro supply chain problems that are strategic in nauture. On the other hand, both DES and ABM are complementry to model entities in the same supply chain to varioius supply networks.

However, the major challengies to be fully and critcally analyse by researchers remains on the ability to match DS and ABM to work together in order to tackle companies problem internally and externally.

Thus, most supply network constrain related to timing is that, the time intended to find optimal solution mostly exceed the parameter of the time considered for executing the the SC respective function. This is more so for the fact that, static planning cannot be applied externally (I.e. outside the organisation) but rather internally, within the organisational boundaries of control as it involves continues or virtual process. Furthermore, the nature of ABM, in decision-making cannot be achieve using centralised approach because, not all information are centrally available.

Finally, it may be possible in the future to identify maximal self-contained system within lager systems that can be centrally control at the same time re-planning in the continuous process. But most likely that system of computational complexity is likely to exists within the boundaries of one company

Reference:

Arvitrida, N., Robinson, S. and Tako, A. (2015). How do competition and collaboration affect supply chain performance? An agent based modeling approach. 2015 Winter Simulation Conference (WSC). [online] Available at: http://ieeexplore.ieee.org/stamp/stamp.jsp?arnumber=7408166 [Accessed 11 Mar. 2017].

Cid Yáñez, F., Frayret, J., Léger, F. and Rousseau, A. (2009). Agent-based simulation and analysis of demand-driven production strategies in the timber industry. International Journal of Production Research, [online] 47(22), pp.6295-6319. Available at: http://ieeexplore.ieee.org/stamp/stamp.jsp?arnumber=7561609&tag=1 [Accessed 5 Mar. 2017].

DAVIS, J., EISENHARDT, K. and BINGHAM, C. (2007). DEVELOPING THEORY THROUGH SIMULATION METHODS. Academy of Management Review, [online] 32(2), pp.480-499. Available at: http://www.jstor.org/stable/pdf/20159312.pdf [Accessed 10 Mar. 2017].

Longo, F. (2011). Advances of modeling and simulation in supply chain and industry. SIMULATION, [online] 87(8), pp.651-656. Available at: http://journals.sagepub.com/doi/pdf/10.1177/0037549711418033 [Accessed 15 Mar. 2017].

Skiadas, C. and Skiadas, C. (2009). Chaotic modelling and simulation. 1st ed. Boca Raton: CRC Press.

Small, M., Walker, D., Tordesillas, A. and Tse, C. (2013). Characterizing chaotic dynamics from simulations of large strain behavior of a granular material under biaxial compression. Chaos: An Interdisciplinary Journal of Nonlinear Science, [online] 23(1), p.013113. Available at: http://web.b.ebscohost.com/ehost/pdfviewer/pdfviewer?sid=7168b51e-03ff-4255-99ea-1cdd085aa4d0%40sessionmgr120&vid=1&hid=125 [Accessed 4 Mar. 2017].