Study of Rail Structure: Risk Analysis and Failure Mode

Â

Study of Rail Structure:Â Risk Analysis and Failure Mode Avoidance

Â

In this case study, a brief overview of railway structure is discussed. Defects related to rail failure are considered essential to frame out the correct maintenance strategy. As it is closely associated with safety of passenger and cargo transportation, hence it retains high risk in terms of human lives and cost of resources. There will always be some risk associated with collisions and derailments but it can be reduced by eradication of the root causes. Exposure and amendment of rail defects are major issues for all rail companies around the world.

There are challenges to the infrastructure maintenance individuals to perform effective inspection and cost effective rectification decisions. If addressed properly these can reduce potential risk of rail breaks and derailments.

Risk assessment and Failure mode avoidance has become a vital constraint for the organisations to decide a cost effective and improved solution that could meet the financial constraints regarding inspection, renewal and replacement of rails and wheels. This study aims to reduce costs and risks related to rail operation by effective approaches. The issues and challenges related to rail maintenance are outlined. The maintenance strategy followed by most railway companies is also defined.

Large Railways infrastructures are the prime manner of transportation in several countries. Improved and better safety measurements are continuously presented but still could not be considered as incidents proof. There will always be some risk related with derailments and other occurrences such as major disruption to services, which can furthered be minimised by detailed examination of the root causes. Some of the causes require improvement in skill and efficiency, for example human error, and some may be improved by optimization of inspection regularity. Therefore, a appropriate thorough study of the defects which develop both on the rolling stock and rail infrastructure is vital to frame out the correct maintenance approach. European Union spends around € 2 billion every year for maintenance and repairing of broken rails (European Commission – Cordis, 2017). It is understood that the consequential cost due to derailment decreases with rise in inspection, lubrication and grinding charges. Risk in railways could be expressed in terms of cost, loss of human lives, infrastructure unavailability, traffic delay and environmental impact which may be caused due to derailment of a train carrying hazardous material.

In this report, different kinds of rail defects and maintenance procedures followed are described. Different risk assessment and failure mode avoidance methods and tools have been discussed briefly in this report. Some of the issues and challenges related to rail maintenance are also addressed with an aim to reduce the total cost and risks associated with rail operations.

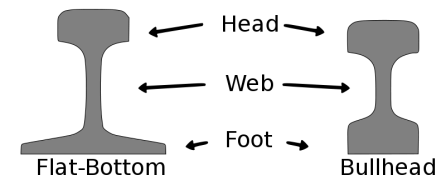

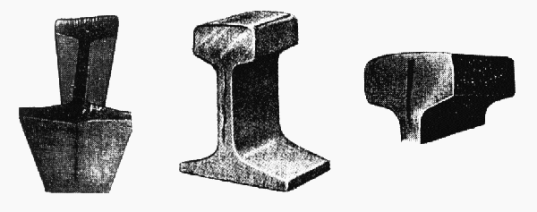

Rails are longitudinal steel members that accommodate wheel loads and distribute these loads over the sleepers or supports, guiding the train wheels evenly and continuously. It is one of the most important components of the track structure. Usually a flat bottom rail is used in conventional railway track, which can be separated into 3 parts: rail head, rail web and rail foot. Many standards are used for rail profiles. (Kumar, 2007) Figure 1 shows the 2 common rail profiles.

Figure 1: Flat bottom and Bullhead rail profiles

The rails must possess sufficient stiffness so that they can act as beams and transfer the concentrated wheel loads to the spaced sleeper supports without excessive deflection between supports. (Ernest and John, 1994)

Due to economic pressure, there is a world-wide trend to increase axle loads, traffic density and speed to reduce the operating cost and increase the efficiency of railways. Axle loads around the world have increased in general from 22.5 to 32.5 Tonnes in last ten years (Allen, 1999). This has led to increased rate of defect formation in rails. Some of the common defects are described in the following sections.

4.1. Shelling

Shelling is a defect caused by loss of material initiated by subsurface fatigue. Shelling normally takes place at the gauge corner of high rails in curves. An elliptical shell like crack propagates in the subsurface parallel to the rail surface. When these cracks emerge on the surface, they cause the metal to come out from the crack area. It is generally eliminated by grinding. (Kumar, 2007)

Figure 2: Shelling caused by Head Checks

4.2. Head Checks

In the crown area, the contact stresses are generally low as it has greater profile radius in

comparison to the gauge side of rail. However, high contact stresses are produced on the high rail’s gauge corner, which usually has curve radius from 1000 to 1500 m. Head

checks are known to occur in tighter (< than 1000 m) curves near the gauge corner of the high rail (IHHA, 2001).

If head checks are not controlled, they can cause a rail break. Grinding is the most common practice to remove head checks. Severe head checks need rail section replacement.

4.3. Squats

Unlike shelling, squats appear in crown area of straight rail sections. They are surface

initiated defects formed by RCF. A squat is formed by two cracks, a leading crack and a

trailing crack. Both these cracks propagate in opposite direction. These defects could be prevented by grinding. (Kumar, 2007)

4.4. Spalling

Spalling occurs, when the surface initiated crack development path is intersected by other similar shallow cracks on the rail head area, a shallow chip of rail material falls out. Spalling is more common in cold climates as rail stiffness increases.

Figure 3: Gauge Corner Spalling in rails

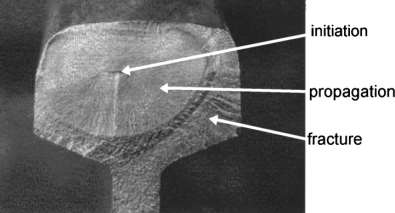

4.5. Tache Ovale

Tache Ovale is a subsurface defect formed around 10-15 mm below the rail head surface (see Figure 4). This is caused by hydrogen accumulation during manufacturing of rail or when poor welding is done in rails. Thermal and residual stresses also contribute to form this defect.

Figure 4: Tache Ovale

4.6. Plastic Flow and Tongue Lipping

Plastic flow occurs in rail head area, the depth of which may be up to 15 mm. Plastic flow

occurs on the field side of the low rail due to overloading. Tongue lipping is also a form of plastic deformation, but it is initiated by surface cracks. These cracks partially separate a layer of material from the bulk of rail. (IHHA, 2001)

4.7. Bolt Hole Crack

Bolt holes appear in the rail web often starting from the fastening point of fishplates. But

these become weak points to resist crack initiation. These cracks have a very high potential to cause rail break and needs urgent replacement.

4.8. Longitudinal Vertical Crack

This is a manufacturing defect, which usually appears in the rail web and may extend in rail

head also. If this crack is intersected by some other crack, it may lead to an early rail

fracture. Odds of sudden fracture due to this become predominant in cold climate.

Figure 5: Longitudinal vertical crack

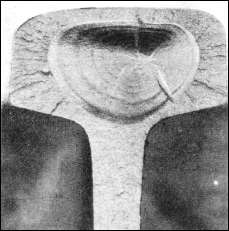

4.9. Transverse Crack

Transverse crack is mostly developed in the cross-sectional area of defective weld joints. A

welding defect may be due to variation in weld material or rail manufacturing defect. Figure 6 shows a Transverse crack develops from the centre of the rail head or the rail foot. Use of clean steel and deeper hardening of rail head may avoid its formation. (Kumar, 2007)

Figure 6: Transverse crack

4.10. Buckling

Lateral buckling in rails is a very common defect in which the rail bulges out on its either side

due to expansion. As the temperature rises, longitudinal expansion in rail takes place.

4.11. Corrugation

Corrugation is a rail flaw consisting of the wave-like wearing of the rail tread visualized as

peaks and valleys, in other words, it is a periodic irregularity of the rail surface (IHHA, 2001),

see Figure 7.

Figure 7: Corrugation in rails

Rail corrugations are the result of a damage mechanism, such as wear etc. Rail corrugations do not pose risk of immediate derailment, but they may be responsible for loosening of rail fastenings, ballast deterioration, increase in noise and vibration level leading to passenger discomfort, etc.

Two main types of corrugations which generally occur in rails are:

- Short pitch corrugations

- Long pitch corrugation

Tables below show the percentage and type of defect detection by different rail infrastructure

companies.

|

Railway |

First |

Second |

Third |

Fourth |

|

Rail track (1999/2000) |

Squats 21.7% |

Vertical/transverse 20.1% |

Horizontal/longitudinal 12.5% |

Bolt holes 9.6% |

|

SNCF (1999) |

Squats 23.4% |

Internal fatigue 11.5% |

Shells 8.4% |

Thermite welds 4.7% |

|

HSPC (1999) |

Thermite welds 31.5% |

Wheel burns 17.2% |

Horizontal split webs 13.3% |

Bolt holes 11.3% |

|

NS (1997) |

Insulated Joints 59.4% |

Transverse defects 18% |

Thermite welds 15% |

Fatigue Failure 5.2% |

|

DB (1996) |

Thermite welds 29% |

Sudden fracture 18% |

Fatigue Failure 16% |

Electric bonds 4.0 % |

|

Banverket (1998) |

Transverse fracture 55.1% |

Welded joint 32.7% |

Horizontal defect 6.1% |

Vertical split 2.0% |

|

HH1 (1999) |

Vertical split heads 34.7% |

Thermite welds 20.3% |

Detail fractures 13.1% |

Bolt holes 12.2% |

|

HH2 (1999) |

Transverse defects 23.6% |

Thermite welds 15.5% |

Wheel burns 13.2% |

Shells 9.6% |

Table 1: Causes of defective rails (Source: Kumar, 2007)

Rail breaks and derailments can cost the rail players in terms of loss of revenue, property, environmental damage or even loss of life. Estimation of these costs and analysis of risks are important in deciding effective maintenance strategies. In simple terms, risk can be defined as the chance or probability of loss, damage or injury. (Reddy, 2004)

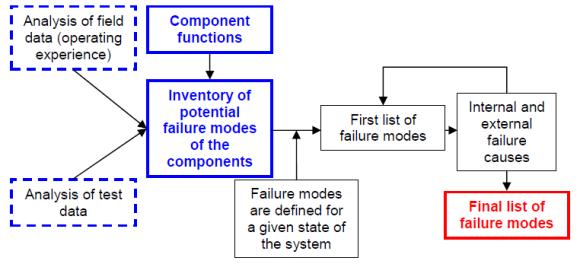

5.1. Failure Mode and Effects Analysis (FMEA)

FMEA is a step-by-step procedure for systematic evaluation of the severity of potential failure modes in a system. This process was originally developed in the 1960s, to analyse the safety of aircrafts, but has been since applied to several other fields, including nuclear power plants and the military. (Villemeur, 1992-A)

Figure 8: Schematic representation of the FMEA. (Source: Villemeur, 1992-A).

5.2. Risk Priority Number (RPN)

Risk priority number (RPN) is a methodology for analysing the risk associated with potential

problems identified during (FMEA) (for details refer Reliasoft, 2005).

Assigning RPN requires the analysis team to rate each potential problem per three rating scales:

- Severity

- Occurrence

- Detection

After the ratings, have been assigned the RPN for each issue is calculated as mentioned below,

RPN = Severity x Occurrence x Detection

Rail maintenance issues can be broadly classified into:

- Inspection issues

- Issues related to rail wear, RCF and rail welding

- Rectification and replacement issues

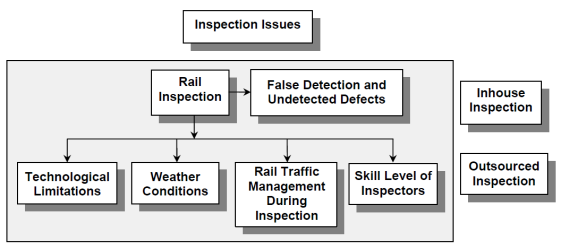

6.1. Rail Inspection Issues

The effectiveness of rail inspection depends on the efficiency and accuracy of the inspecting

equipment. It also depends on the skill and experience of inspectors. Error in inspection is an important issue and its reduction is a big challenge. This mainly depends on the technological limitations of the inspection equipment and the skill level of the rail inspectors.

Figure 9: Rail inspection issues (Source: Kumar, 2007)

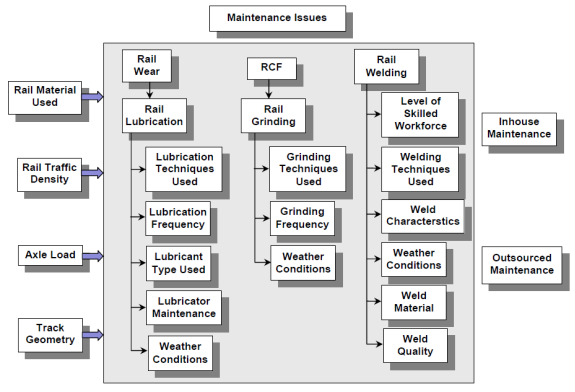

6.2. Issues related to Rail Wear, RCF and Rail Welding

Figure 11 outlines the rail maintenance issues. The following sections briefly describe some

of these issues.

Figure 10: Rail maintenance issues (Source: Kumar, 2007)

6.2.1. Rail Wear Issues

Wear occurs due to interaction of rail and wheel. It includes mild and severe wear. Mild wear takes place slowly but severe wear is often much faster. Severe wear is predominant in curves and occurs dry conditions. Lubrication techniques are used to prevent such wears.

Four commonly used techniques which are followed for rail-wheel lubrication are:

- Top of rail lubricators

- Wheel flange lubricators

- Wayside lubricators

- On board lubricators

6.2.2. Rolling Contact Fatigue (RCF) Issues

In the late 1990s RCF accounted for about 60% of defects found by East Japan Railways, while in France (SNCF) and UK (Railtrack) the figures were about 25% and 15%,

respectively. RCF is a major future concern as business demands for higher speed; higher axle loads, higher traffic density and higher tractive forces increase (see Cannon et al, 2003).

Rail grinding removes surface metal from the rail head. It is done mainly with intensions to control RCF defects and rail wear. Rail grinding became increasingly recognized for controlling RCF defects from 1980 onwards, prior to that it was mainly focused on corrugation removal.

6.2.3. Rail Welding Issues

Small imperfection in welds can cause cracks to initiate. A defect free weld requires skilled

workforce, better weld material along with improved welding techniques and equipment.

6.3. Other Issues affecting Rail Wear, RCF and Rail Welding

Risk and cost are analysed by rail infrastructure operators in maintenance decisions. It covers rail lubrication, rail grinding and rail weld.

Other important issues are:

- Rail material

- Rail traffic density and axle load

- Track geometry

In Conclusion, first a brief overview of rail structure is discussed. Then, diverse range of rail defects and degradation processes have been studied. From the literature analyses done, it is interpreted that there is a need for better ways to monitor and predict rail defects over a period based on operational conditions and maintenance tactics. A good knowledge of risk along with an idea of the methods used for risk analysis is also required. Hence, before improvement of any model or any empirical relationship associated with risk and failure, there should first be a familiarity with risk management tools and failure mode avoidance. This study focuses on some such tools.

Also, the issues and challenges related to rail maintenance are discoursed. The aim is to reduce risks related to rail operation that leads to failure mode, by effective decisions associated to rail inspection, grinding, rectifications lubrications, and rail replacements. Some of the challenges in this area include development of cost effective maintenance decisions, reliability and availability of logistics support, which include availability of capable equipment, skilled personnel and availability of rail track.

8.1. References

Allen, R., (1999) Finding best practice at the wheel/rail interface, International Railway

Journal, Volume 6, pp. 48-50.

European Commission – Cordis (2017) AutoScan – Rail inspection. Available from: sighted: [February 2017]

Cannon, D. F., Edel, K.O., Grassie, S. L. and Sawley, K. (2003) Rail defects: an overview,

Fatigue & Fracture of Engineering Materials & Structures, Volume 26, October 2003, pp.

865-886.

Ernest, T. S. and John, M. W. (1994) Track Geometry and Substructure Management,

Thomas Telfold.

IHHA (2001) Guidelines to best practices for heavy haul railway operations: wheel and rail

interface issues, International Heavy Haul Association, May 2001, Virginia, USA.

KUMAR, S. (2007). Study of Rail Breaks: Associated Risks and Maintenance Strategies. Lulea Railway Research Center (JVTC)

MIL-STD-1629A, (1980) Military Standard Procedures for Performing a Failure Mode,

Effects and Criticality Analysis, Department of Defence, USA. Available from: http://www.uscg.mil/hq/g-m/risk/e-guidelines/RBDM/html/vol4/Volume4/Toolspec_

Rec/FMEA/MIL-STD-1629A.pdf sighted: [February 2017]

Reddy, V. (2004) Modelling and Analysis of Rail Grinding & Lubrication Strategies for

Controlling Rolling Contact Fatigue (RCF) and Rail Wear, Master Thesis, Queensland

University of Technology, Brisbane, Australia.

Reliasoft (2005) Examining risk priority numbers in FEMA, Reliability Edge, volume 4,

issue1. Available from: sighted: [February 2017]

VILLEMEUR, Alain (1992-A, 1992-B). Reliability, Availability, Maintainability and Safety Assessment, A: Vol. 1: Methods and Technique. B Vol.2: Assessment, Hardware, Software and Human Factors: John Wiley & Sons.

8.2. Figures:

Figure 1:

Figure 2:

Figure 3:

Figure 4:

Figure 5:

Figure 6:

Figure 7:

Figure 8:

VILLEMEUR, Alain (1992-A, 1992-B). Reliability, Availability, Maintainability and Safety Assessment, A: Vol. 1: Methods and Technique. B Vol.2: Assessment, Hardware, Software and Human Factors: John Wiley & Sons.

Figure 9 and 10:

KUMAR, S. (2007). Study of Rail Breaks: Associated Risks and Maintenance Strategies. Lulea Railway Research Center (JVTC)