Transformation Temperature in SMAs

This report contains four sections. The first section discusses ways to control the transformation temperature in SMAs. The effect of alloy composition on martensitic transformation, the effect of precipitation process on the transformation temperature of SMAs, and the effect of thermo-mechanical treatment on the properties of SMAs are examined in this section. The second section presents the standard thermomechanical training procedures to obtain the shape memory effect in SMAs in various applications. The third section presents the parameters for improving the quality of interface. Finally, the forth section discusses the effect of processing on the physical nature of the SMA elements in order to guide the coating manufacturing process.

1. CONTROLLING THE TRANSFORMATION TEMPERATURE IN SMAs

The transformation temperature in SMAs can be controlled in two ways: by alloy composition and by heat treatment [Otsuka, Ren, 2005]. When changing alloying composition or by thermo-mechanical treatment, which modified the microstructure by introducing precipitates, the transformation temperature is modified.

1.1 Effect of alloy composition on martensitic transformation

Martensitic transformation determines all critical properties of SMAs, including superelasticity and SME. One of the most significant material properties in NiTi SMAs is considered the AF transformation temperature, since it governs the transition between the superelastic and the shape memory properties. Modifying the composition of NiTi phase changes significantly the transformation temperature. Studies aiming in determining the effect of varying the composition of NiTi showed a general trend that an increase in titanium concentration results in raising the transformation temperature [Russell, 2001]. In fact, a change of 1% in the quantity of titanium or nickel will cause a 100°C change in the transformation temperature. Hence, small deviations in composition will considerably change the transformation temperature and the resulting properties. The composition where superelastic NiTi SMA is typically used is about 51(at.%) Ni (Ni-rich SMA) [Russell, 2001].

1.2 Effect of precipitation process on the transformation temperature of SMAs

The transformation temperature of SMAs can be progressively changed by precipitating Ni-rich phases from the surrounding NiTi matrix, starting from a given NiTi alloy composition. The precipitation processes of Ti-52 at.% Ni and Ti-50 at.% Ni, for example, leads to the formation of a series of Ni-rich precipitates for various heat treatment conditions [Wayman, Honma, Nishida, 1986]. Ni-rich phases precipitate from the surrounding NiTi matrix, forming coherent precipitates between heat treatments of 300°C-450°C [Wayman, Honma, Nishida, 1986].

When Ni is depleted from the NiTi phase, the concentration of Ti in the NiTi phase raises. This precipitation process causes the transformation temperature to increase [Wayman, Honma, Nishida, 1986]. A change in AS of 150°C has been observed during aging of Ti-51.5 at.% Ni at 400°C [Melton, 1990].

Studies of the precipitation process of Ti-50.8 (at.%) showed that at a temperature of 450°C ATraises quickly with the heat treatment time [Pelton, 2000]. At about 575°C, the maximum precipitation rate occurs at higher temperature, where annealing dominates and different precipitates are formed. The locations of the highest increase in transformation temperature rate depend on the formation and growth process related to the precipitation of nickel-rich phases[Russell, Pelton, DiCello, 2003].

The NiTi matrix composition is in equilibrium with Ni3Ti precipitates when the temperature increases and has less Ni content. Hence, at elevated temperature (e.g. more than 800oC) the matrix is composed of NiTi with low Ni content. Therefore, a higher MS temperature is achieved compared to the matrix at 700 oC [Paryab et al., 2010].

Microstructures change during aging in terms of precipitation volume fraction, size, and precipitate distribution in the material. When the aging time is increased, the effect on precipitation size is increasing and is greater than the effect of applied stress [Khalil-Allafi et al., 2002]. Also, the effect of various annealing conditions on the martensitic transformation of near-equiatomic NiTi SMA are important for annealing up to 550°C [Kuś, Kłysz, 2012].

1.3 Effect of thermo-mechanical treatment on the properties of SMAs

NiTi components are usually subjected to a series of thermal-mechanical treatments during the fabrication process. By applying heat treatment without any mechanical stress during shape setting of the material, results in uniform properties throughout the specimen [Liu et al., 2006].

During constrained aging, Ni4Ti3 rich precipitates are formed and are preferentially aligned along the external tensile stress regions [Bidaux, Gotthardt, Bataillard, 1998]. During the precipitation process, coherent Ni4Ti3 precipitates are formed in lenticular shapes [Otsuka, Shimizu, Tadaki, 1998]. During constrained aging, the external stress can affect the formation and shape of the lenticular precipitates [Kainuma, Matsumoto, Honma, 1987; Eggeler, Bojda, Dloughy, 2005; Li, 1999]. An applied stress tends to increase the size of the precipitates with increasing aging time. An applied stress will encourage the formation of elongated Ni4Ti3 precipitates to release internal stresses [Carroll et al., 2004].

As the transformation temperature increases above room temperature due the formation of Ni-rich precipitates influenced by an applied strain, the NiTi specimen is mainly in the martensite phase (martensite has less mechanical properties due to its atomic structure).

The effect of constrained aging on the ultimate tensile stress of NiTi is not largely published in literature. Nevertheless, the effect of cold working and heat treatment on the ultimate tensile stress of Ti-50.8 at.%Ni has been investigated [Masao, Pelton, 2006]. An increase in tensile strength due to precipitation hardening occurs between 350°C and 450°C at 30% original cold work. At elevated temperatures (between 500°C and 600°C) annealing effects are predominant causing tensile strength to decrease.

Even short-time (several minutes) heat treatments at moderate temperature (about 500°C) can influence the mechanical properties and transformation behavior of SMAs [Vojtěch, 2011]. Annealing at 410-450°C can cause strengthening of a SMA specimen due to precipitation. At elevate temperatures of annealing, the precipitates become coarser and recrystallization takes place, which leads to the decrease of strength.

When a SMA is subjected to cold work its yield strength is increased, however, there is a reduction in the heat recoverable strain of the material. On the contrary, when the SMA is subjected to annealing treatment these phenomena are reversed and the MS temperature is increased, however, the mechanical stability is significantly reduced. This is due to the fact that cold working, without annealing, damages the martensitic plateau on the stress-strain curve, therefore, the material exhibits a high yield strength, but the shape memory property is poor [Russel, Hodgson, Basin, 1997]. Annealing restores the SME, but lowers the yield strength. This should be taken into account when choosing a NiTi SMA to be used as actuator, where a high MS is achieved through annealing to alter the effects of initial cold work. For this reason, NiTi SMAs with about 10 % Cu are better suited for actuator applications [Gallardo Fuentes et al., 2002]. However, since cyclic stability is not a parameter for choosing NiTi SMAs for structural applications, such process is not necessary for the development of NiTi SMA coatings on metallic substrates.

2. THERMOMECHANICAL TRAINING PROCEDURES TO OBTAIN THE SHAPE MEMORY EFFECT

Training SMA materials sets the original shape that the material will “remember” after heating. Various training techniques can be applied to obtain the SME in different SMA systems. Training methods that are commonly used include: (a) the one-way SME cycling, which is based on martensite deformation, then recovery either constrained or unconstrained [Lahoz, Gracia-Villa, Puertolas, 2002; Liu, Van Humbeeck, 1998; Wang et al., 2002; Shelyakov et al., 1995; Meng et al. 2006; Meng et al. 2004], (b) superelastic cycling, which is based on stress cycling at a temperature higher than [Perkins, Sponholz, 1984], thermal isobaric cycling [Stalmans, Humbeeck, Delaey, 1992; Stalmans, Humbeeck, Delaey, 1991; Contardo, Guenin, 1990; Hebda, White, 1995], which is based on cycling the temperature during martensitic transformation while keeping the stress level constant [Lahoz, Puertolas, 2004; Liu, McCormick, 1988; Scherngell, Kneissl, 1998; Wanget al., 2001], and combination of the previous two methods [Nagasawa et al., 1974].

All the above training methods have in common the repeated development and reduction of specific martensite variants, which causes the creation of stable dislocation groups [Norfleet et al., 2009; Delville et al., 2011; Simon et al. 2010]. An alternative technique from the previously mentioned is aging under constraint, and can be used to obtain one-way SME in Ni-rich NiTi SMA materials. During aging under applied stress, the formation of coherent precipitates is promoted in preferred orientations, causing formation of specific variant martensite along oriented internal stresses [Nishida, Honma, 1984].

Comparing the above training techniques, it was found that thermal cycling during martensite transformation under constant stresses shows better magnitude and stability of generated SME [Liu, McCormick, 1990].

Training techniques are mainly applied to SMAs in order to obtain two way shape recovery. The above-described training procedures use thermomechanical treatments so that the SMA remembers the shapes at high and low temperatures, repetitively. Upon heating, a SMA specimen “remembers” the shape at elevated temperature (recovering the austenite shape), while “forgets” the deformed shape at low temperatures. Nevertheless, the SMA can be trained in order to “remember” the shape at low temperatures too. The training procedures described above are therefore based on repeating many times back and forth, through the region of phase transformation, of a thermo-mechanical cycle.

For some applications, the SMA material must be cyclically loaded in order to stabilize its response (i.e. the Transformation-Induced Plastic – TRIP strain and hysteresis loop). Similarly, cyclic training is needed in case of applications requiring two-way SME, (i.e. the SMA material “remembers” the high and low temperature shapes without to re-bias the force). Under the InnoSMART project, for which SMA coatings deposited on aluminium substrates are being developed for modular structures made of beams for aeronautical applications, such as the conventional aircraft wing box and the fuselage structures, no SMA training of any kind is required. For the aforementioned application related to InnoSMART, the SMA material is required to contribute to the stiffness and rigidity of the metallic core beam to withstand the expected loading conditions safely and enhance the fatigue properties by inducing compressive stresses to the beam through its activation one single time at a temperature that is lower than temperature regime of the application.

3. PARAMETERS FOR IMPROVING THE QUALITY OF INTERFACE

The adhesion between the coating and the substrate as well as its cohesion among splats are the main features of a thermal spray coating. The quality of a coating is principally defined by the adhesion bond strength while the coating wear behavior is determined by the cohesion bond strength [Vencl et al., 2011; Bull and Rickerby, 2001; Leigh and Berndt, 1994].

In thermal spray coatings, the bond between coating and substrate is essentially mechanical, even if some chemical bonding is also present due to the thermal energy source of the process [Day et al., 2004]: during thermal spray, particles flow and lock into the roughness of the substrate after their solidification [Lufitha, 2001].

These interlocking forces cause the adhesive strength of the coating and provide its quality [Bao et al., 1997]. Therefore, the nature of the substrate surface and the interface between coating and substrate are key aspects for high quality thermally sprayed coatings.

To ensure maximum coating bond strength and an acceptable microstructure, thermally sprayed coatings require a pre-treatment to provide surface cleaning and a surface roughening [Varacalle et al., 1995; Day et al., 2004; Nicholas and Scott, 1985].

Several studies discussed the relationship between adhesion and surface roughness [Fuller and Tabo, 1975; Amada et al., 1992; C¸olak et al., 2012].

In accordance with the standard BS EN 2063 and Surface Preparation for Coating by National Physical Laboratory (2000), surface to be thermally sprayed should be treated by grit blasting process that produces a roughened surface for subsequent coating processes and removes surface contaminants [Varacalle et al., 1995; Day et al., 2004] such as oxide tarnish, rust or mill scale, on metallic [Bishop, 2005], at the same time.

Grit blasting is a relatively simple process: hard grit is propelled by compressed air (Dry Grit Blasting), or occasionally by high-pressure water (Wet Grit Blasting), towards the substrate that needs cleaning or roughening [Ebnesajjad, 2011]. Practical grit size ranges are -10 +30 mesh (coarse), -14+40 mesh (medium), and -30 + 80 mesh (fine). Generally, coarse grit is used for coatings thicker than 250 µm and best adherence; medium grit is used for coatings thinner than 250 µm, fair adherence and smooth surfaces; and fine grit is used for coatings thinner than 250 µm, used in ‘as-sprayed’ conditions without finishing [Roseberry and Boulger, 1977; Varacalle et al., 1995; Pawlowski, 2008]. It is worth highlighting that the optimum size for the work in hand can only be determined by experiments.

Available grit types are: fused alumina, silica, quartz, chill-cast iron shot or silicon carbide [Bishop, 2005].

The kind of the substrate to be abraded and the chemical compatibility in the finished coating system must be taken into account for the selection of the proper grit types to use [Bishop, 2005; Varacalle et al., 1995]: softer metals such as aluminum, copper, and their alloys may be abraded by using alumina, sand, and silicon carbide especially, with lower air pressures [Varacalle et al., 1995].

Grit blasting air pressure ranges between 210 and 620 kPa (30 to 90 psi), with typical blasting distances in the range of 50-150 mm (2 to 6 in.); diameter openings of grit blast nozzle are generally from 6 to 10 mm (0.25 to 0.375 in.); the blasting angle to the substrate should be about or slightly less than 90° [Varacalle et al., 1995].

The effect of the process parameters of grit blasting on roughness of blasted surface was investigated highlighting that the surface roughness, defined in terms of parameter average roughness Ra, generally increases with an increase of grit size [Mellali et al., 1997; Maruyama and Kobayashi, 2004; Mohammadi et al., 2007; Day et al., 2004] while the effect of blasting distance, blast pressure on the surface roughness and blasting angle was uclear [Mellali et al., 1997; Amada et al., 1999; Bahbou et al., 2006; Sen et al, 2010]. Several studies showed that an increase in surface roughness occurred increasing grit blasting pressure and decreasing blasting distance [Poorna Chander et al., 2009; Varacalle et al., 2006; Day et al., 2004]. However, below a critical blasting distance the surface roughness was low and the surface roughness increased with blasting angle till the angle is around 75° [Poorna Chander et al., 2009].

Also the effect of the time blasting was studied: the maximum Ra was reached after relatively short blasting times and no influence on the surface roughness for longer processing was found [Mellali et al., 1997].

The influence of grit-blasting parameters on the bond strength was studied in several works: for air plasma spraying, Bahbou et al. (2006) examined the influence of blasting angle on bond strength of Triballoy 800 on Ti-6Al-4V substrate and reported that an increase of the blasting angle from 45° to 90° caused an increase of both the surface roughness (Ra) and the adhesion strength; on other hands no correlation between bond strength and surface roughness for Co-based alloy and Al2O3 were observed by Day et al. (2004) and Amada et al. (1999), respectively.

Regarding HVOF sprayed coatings, the limited data available reported that a higher surface roughness was obtained by increasing blast pressure [Staia et al., 2000] or by increasing grit size [Osawa et al., 2004], resulting in an increase in bond strength.

Other investigators observed that the interface between coating and substrate can be activated also by heating the substrate surface, providing a higher adhesion of the coating [Pershin et al., 2002; Tian et al., 2016]. Pershin et al. (2002) observed that a plasma-sprayed nickel coatings revealed an increase of adhesion strength when substrate temperature was kept in the range 25-650°C during the spray, because coating porosity decreased with increasing substrate temperature above 300°C. A lower value of adhesion strength was obtained when the substrate was heated and gradually cooled before the deposition; in this way, oxide films were formed on their surface, which acted as a thermal barrier and reduced the cooling rates of impinging droplets, preventing the mechanism of locking between droplets and substrate [Pershin et al., 2002; Tian et al., 2016]

4. EFFECT OF PROCESSING ON THE PHYSICAL NATURE OF THE SMA ELEMENTS

This section aims to determine the processing conditions needed as well as the geometry of the substrate for the SMA coating on aluminium beam element to obtain a SME.

In particular, this section discusses the:

- Effects of transformation-induced plasticity (TRIP) and microstructure in order to enable selection of optimal composition/microstructure for the SMA coating deposition.

- Substrate geometry required for deposition of NiTi coating.

- Heating temperature of the SMA material, which is a critical parameter for the SMA coating to obtain a shape memory effect.

- Relation between the heating temperature and the Ni-Ti microstructure.

Finally, the influence of porosity in a SMA on the superelasticity of the material is briefly discussed at the end of this section, since during deposition of SMA coating on a metallic substrate the densification of the coating may become an issue.

Since the SMA material of choice is binary Ni-Ti (as determined in D1.1), there is no need to mix the SMA elements with other compounds. This would happen in the case of corrosion-prone alloys (e.g. ferrous alloys) where other compounds (e.g. copper) would offer corrosion resistance. However, mixing of SMA elements with precipitate compounds in the microstructure (obtained after appropriate heat treatment) enables tailoring of the phase transformation temperatures of the Ni-Ti SMA. The precipitates are non-transforming compounds, which shift the phase transformation temperatures, decrease the phase transformation strain, and suppress the TRIP.

In order to enable Ni-Ti material to be used as SMA coating, the nature of SMA elements (i.e. Ti-Ni alloys of different composition) were studied, as well as the effect of different microstructures producing precipitates of different size. The influence of the composition and precipitates on the thermomechanical properties are examined.

Ni-Ti material was considered in two different compositions that offer both advantages and disadvantages for using them in our application of choice:

(a) Equiatomic composition, which is prone to large amount of TRIP since there are no precipitates to stabilize the response, it has a fixed transformation metrics and high transformation strain [Lagoudas, 2008; Lagoudas et al., 2012].

(b) Ni-rich Ni50.8Ti (at.%) composition, in which precipitates can be formed by appropriate heat treatment, thereby stabilizing the response of the material against TRIP. Therefore, the Ni-rich composition offers tuneable transformation metrics, adequate resistance to TRIP, but lower transformation strain [Lagoudas, 2008; Lagoudas et al., 2012].

The role of precipitates in the Transformation Induced Plasticity is explained below. During phase transformation there is deformation misfit between the martensitic and austenitic phases present in the material. At this instance, the stress can locally exceed the material’s yield strength producing local plasticity. By inducing obstacles (i.e. precipitates) to the movement of dislocations we can obtain less amount of TRIP. The precipitates, therefore, cause transformation strains to decrease (by the rule of mixtures), since they are non-transforming particles [Baxevanis, Parrinello, Lagoudas, 2016]

In the case of Ni-Ti SMA with equiatomic composition, where there is absence of precipitates, there is more plasticity in the material, but also more transformation strains. However, in the case of Ni-rich material, the presence of precipitates causes the plastic deformation to be suppressed [Baxevanis, Lagoudas, 2015]. This means that in the case of an application that requires that the SMA material is used in a large number of cycles (e.g. in an actuating device) the composition of choice is Ni-rich. However, in an application requiring the SMA material to be used in a few cycles (e.g. the SMA coating structural application of the InnoSMART project) Ni-Ti SMA with equiatomic composition can also be used, as well as Ni-rich material.

For the above reasons, it has been decided that the first material of choice for coating application in the InnoSMART would be the Ni-rich Ni50.8Ti, while equiatomic Ni-Ti remains an alternative material to reduce the project’s risk, in case that the Ni-rich material fails to achieve its objectives.

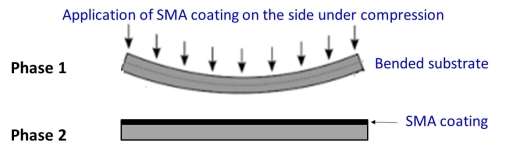

In addition to Ni-Ti composition, the geometry of the aluminium substrate necessary for deposition of the coating plays an important role in an effort that the SMA coating obtains a shape memory effect (Figure 1). To this regard, a two-phase coating deposition process is being proposed. During Phase 1, the SMA coating will be firstly deposited on the compressive side of the bended aluminium substrate. After coating deposition, the SMA coating/substrate structure will be left to reach ambient temperature, while the structure remains bended, so that the Ni-Ti coating will be at the martensitic state. Since, at this stage, no stress is applied on the coating, the SMA coating material is self-accommodated matrensite – twin structure. This completes Phase 1. During Phase 2, the SMA coating/substrate structure will be unloaded, regaining its original shape. The SMA coating, however, will be found under tension (detwinning state). By heating of the structure, the SMA coating will transform to austenite, therefore, compressive stresses will be induced in the structure as the SMA coating is trying to change its shape by shrinking.

Figure 1 SMA coating deposition process on an aluminum substrate in order to for the coating to obtain the SME

One of the most important parameters for the coating to obtain a shape memory effect is the appropriate aging heat treatment.

Ni-Ti coating in equiatomic composition requires a high phase transformation temperature in order to obtain a shape memory effect, while the phase transformation temperature of Ni-Ti coating in Ni-rich composition can be tailored depending on its microstructure (i.e. on the presence of precipitates). Such tailoring of the phase transformation temperature of Ni-rich coatings can be achieved through heating during the Phase 2 of the above described fabrication process.

This heating temperature depends on the SMA material composition and microstructure. In equiatomic Ni-Ti material, the austenite appears at a phase transformation temperature of about 107οC. However, for the as-received SMA material with Ni-rich composition, where there is no presence of precipitates, the austenitic temperature is at 35oC. The presence of precipitates in the material’s microstructure influences the austenitic temperature. For instance, in Ni-rich composition, with incoherent precipitates with the austenite matrix of heterogeneous distribution (with average size of particles about one micrometer), the austenitic temperature is above 35oC, while in Ni-rich composition, where coherent nano-precipitates of homogeneous distribution are formed, the austenitic temperature is below 35oC.

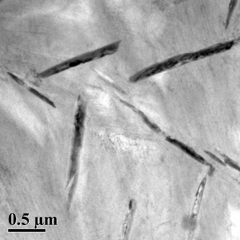

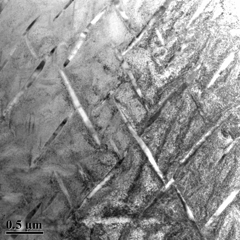

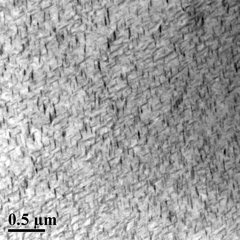

During processing, Ni-rich Ni-Ti SMA material was subjected to aging [Saburi, 1998], where Ni4Ti3 precipitates were formed [Tadaki et al., 1986]. Figure 2 presents TEM (transmission electron microscopy) images of Ni-rich Ni50.8Ti (at.%) SMA after stress-free aging at 500oC for 24 hours. The Ni4Ti3 precipitates are incoherent and have rhombohedral atomic structure and lenticular shape [Saburi, 1998], as it is observed in Figure 2.

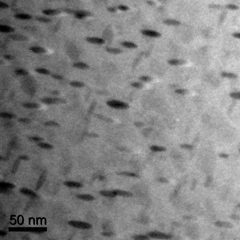

Figure 3 shows TEM images of Ni-rich Ni50.8Ti (at.%) SMA after stress-free aging at 300oC for 100 hours. During processing, the Ni-rich Ni-Ti SMA material was subjected to the aforementioned aging heat treatment where Ni4Ti3 coherent nano-precipitates were formed.

(a)(b)

Figure 2 TEM images of Ni-rich Ni-Ti matrix with Ni4Ti3 incoherent precipitates after aging at zero stress at 500oC for 24 hours. The images show formation of diverse crystallographic Ni4Ti3 precipitate variants (a) close to and (b) distant from a grain boundary

(a)(b)

Figure 3 TEM images at different scales of Ni-rich Ni-Ti matrix with Ni4Ti3 coherent nano-precipitates after aging at zero stress at 300oC for 100 hours

During the deposition of SMA coating on a metallic substrate the densification of the coating may become an issue. However, experimental results demonstrated that the porous Ni-Ti SMA exhibits pseudoelastic behaviour [Lagoudas, Entchev, Vandygriff, 2002]. The study was based on mechanical tests under compressive loading of porous Ni-Ti SMAs with various levels of porosity. These tests have clearly shown that porous SMA materials develop transformation and plastic strains during the martensitic phase transformation [Lagoudas, Entchev, Vandygriff, 2002].

Martensitic transformation determines all critical properties of SMAs, including superelasticity and SME. The final transformation temperature is considered as one of the most significant material properties in Ni-Ti SMAs, since it governs the transition between superelastic and shape memory behaviour. The transformation temperature in SMAs can be controlled by choosing proper alloy composition and appropriate aging heat treatment, which modifies the microstructure by introducing precipitates. Even short-time heat treatments at moderate temperatures can influence the mechanical properties and transformation behaviour of SMAs.

For specific SMA applications, such as actuators, cyclic training is required in order for the material to stabilize its response and memorize high and low temperature shapes without any applied force. For structural applications, however, such as SMA coating deposited on metallic substrates, no SMA training is required. This is because the SMA has to contribute to the stiffness and rigidity of the structure to safely withstand the expected loads, as well as to possess improved fatigue behaviour by inducing to the beam compressive stresses through its single-time activation at an appropriate temperature.

Ni-Ti coatings were considered in two different compositions: (a) equiatomic, which is prone to TRIP, since there are no precipitates, and has a fixed transformation metrics and high transformation strain, and (b) Ni-rich Ni50.8Ti (at.%), where precipitates can be formed by appropriate heat treatment, thereby stabilizing the material’s response against TRIP. Hence, Ni-rich composition is preferable since it offers tuneable transformation metrics, adequate resistance to TRIP, but lower transformation strain.

For an application, such as an actuator, requiring the SMA to be used in a large number of cycles, the material composition of choice would be Ni-rich. However, in an application, such as SMA coating for structural components, requiring the SMA to be used in a few cycles, both Ni-rich and equiatomic Ni-Ti can be utilized. It was, therefore, decided that while Ni-rich would be the material of choice for coating application, equiatomic Ni-Ti remains an option as an alternative material, in case that the Ni-rich material fails to achieve its objectives.

The SMA coating, in order to have a SME, should to be subjected to appropriate processing conditions and be deposited on a metallic substrate with proper geometry according to a specific process.

To this regard, a two-phase coating deposition process is being proposed. The process is based on depositing the SMA coating on the compressive side of a bended aluminium substrate beam. At the final stage, heating the structure will lead the SMA coating to transform to austenite, inducing compressive stresses as the SMA coating is trying to change its shape by shrinking.

In addition, appropriate aging heat treatment is of paramount importance for the coating to obtain a shape memory effect. Ni-rich Ni50.8Ti (at.%) SMAs, after stress-free aging at 500oC for 24 hours, lead to the formation of Ni4Ti3 incoherent precipitates, while by subjecting the material to aging at 300oC for 100 hours, there is formation of Ni4Ti3 coherent nano-precipitates. This fact directly influences the SMA coating transformation temperature, where in the first case it is above 35oC, while at the latter case the austenitic temperature is lowered below 35oC.

The quality of a coating is mainly determined by the quality of coating/substrate interface. In thermal spray coatings, the bond between coating and substrate is essentially mechanical. To ensure maximum coating bond strength, thermally sprayed coatings require a pre-treatment, such as grit blasting, to provide surface cleaning and a surface roughening. The nature of the substrate to be abraded and the chemical compatibility with the coating have to be considered for the selection of proper grit type.

In addition, grit blasting air pressure, blasting distance and blasting angle to the substrate are important parameters affecting the quality of the SMA coating/substrate interface. Softer metals, such as aluminium alloys, may be abraded using alumina, sand, and silicon carbide with lower air pressure. Moreover, heating the substrate followed by gradual cooling before coating deposition should be avoided since it would decrease the interface adhesion strength due to formation of oxide films on the substrate.

Finally, it is recognized that during the deposition of SMA coatings on metallic substrates the densification of the coating may become an issue. However, there is evidence that porous Ni-Ti SMA still exhibit adequate pseudoelastic behaviour.