Transmission of Wireless Message based on Embedded System

Transmission of Wireless Message based on Embedded System with Robotic Arm

INTRODUCTION:

2.1) This career episode describes the project “Transmission of Wireless Message based on Embedded System with Robotic Arm”. I started off this project under the guidance of my assistant professor and with a team of two engineers including myself, during the last three months (October 2012-December 2012) of 7th semester while pursuing Bachelors of Engineering (Electronics and Communication) from Gujarat Technological University, India. The assigned duration for the project was three months and with the help of my professor, we were able to complete each task of the project on time. This project was implemented as a part of my academic curriculum “Wireless Communication“. For this project, I was working as an Electronic Engineer.

BACKGROUND:

2.2) In this universe of learning and understanding all the things that are nearby, is controlled through machines, having the ability to compute. This specialized excellence and integration in various departments can prompt an exceptional alteration in everyone’s lives particularly interchanges department. Because of different alterations in innovations, numerous frameworks are made with stunning advancements. The most innovative one is the Embedded Systems. Embedded system is the advancement or further improvement of computer science framework. Its application give colossal chances to innovative utilization of PC innovation. Verging on each new framework presented in the business sector is a case of Embedded System.

2.3) The framework which we have created is a utilization of an Embedded System. At first, we began off with the manner of thinking of building up a wireless message roundabout model which could help both establishments and in addition enterprises. A further research into the framework prompted the possibility that equivalent framework can act like a concentrated framework for ambitions, for example, managing, observing plus correspondence keeping aside human intercession.

2.4) Project Objective

To describe in few sentences, my project’s main deliverable was to send the data from one place to another place through transmitter and receiver using RF technology. The microcontroller works as brain of the unit. Microcontroller controls the functions of the LCD, conveyor belt motors, and vertical/horizontal motor track motor in order to perform desired action/task using robotic arm (mechanical hand).

2.5) My roles and responsibilities included:

- Selection of electric components

- Simulation of Motors, LED and LCD using Proteus

- Programming of ATMEGA16 microcontroller using BASCOM software.

- Assist in constructing mechanical hand and conveyor belt

- Schedule weekly meetings to discuss goals and achievements

- Assist in maintaining documentation.

2.6) Project mechanism

PERSONAL ENGINEERING ACTIVITY

2.7) Training

We decided to go for training first since it really helped us to move forward without a hurdle in my work. It is required for the beginners to undergo a training session in order to acquire knowledge and develop skills at an industry level. This also helped me to understand the difference of work culture between industry and college level. In the practice session under the guidance of my professor, initially we discussed the design process of the project and different components to be used on the transmitter and receiver side such as microcontroller, USB to UART convertor, encoder, and sensors. I also learnt the software Proteus and BASCOM for the simulation of motors, LED, LCD and programming the microcontroller. Furthermore, safety training sessions were also given to build mechanical hand and designing circuit in the safest way possible. Before the implementation of any task, we were given proper safety measures.

2.8) Software

Before starting the hardware implementation, I decided to learn the software Proteus. Proteus is an open source software used for simulation of electric circuit and has the ability co- simulate and interact with software running in the microcontroller. I learnt this software by referring tutorial videos and simulating sample electric circuits. In this project, I used Proteus for the simulation of motors, UART, LED and LCD. Furthermore, I also used the software named BASCOM. BASCOM AVR is an intense and simple to-use compiler for the AVR arrangement of smaller scale controllers created by Atmel. It took me hardly any time to master this software since it was very easy. The system accompanies an extremely easy to use interface and an arrangement of straightforward summons, and gives more adaptability than different projects in this classification. Anyone with some fundamental learning of C or C++ can compose a fruitful system utilizing BASCOM, as the majority of its capacities and its announcement structure is like those in C.

2.9) Hardware implementation

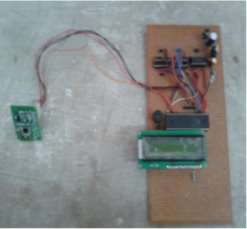

After training, I started my research to select the most appropriate components for hardware implementation refereeing and comparing datasheets of each component. Keeping in mind the guidelines of designing a circuit, on the transmitter side included computer, usb to serial converter, microcontroller, encoder and transmitting module. Whereas on the receiver side, I used receiving module, microcontroller, LCD display, IR and metal sensors. For the conveyor belt, we used two DC motors to pass an object on the belt. In this project, we also introduced a robotic arm (mechanical hand) as an application which can reduce the human efforts and controlling can be done effectively. There were some difficulties which we faced while constructing the mechanical hand i.e. we built the arm using two DC motors but while using it, we realized that it delivers low torque. Therefore, we discussed this issue with our professor and we came up the solution to build the arm using a combination of BO and DC motor. We designed this mechanical hand at very low cost which is very efficient and can be used in many production industries for packaging or assembling goods which mitigates physical labor, consumes less time and reduces risks as well. The mechanical hand in this project was used to pick an object from the conveyor belt and put it to a required place as per the application.

Â

Conveyor BeltRobotic Arm

Â

Transmitter SectionReceiver Section

2.10) Pseudo flow of the system:

- Input is provided via Computer which is converted in to serial using UART.

- The serial data is sent to the microcontroller which is then encoded using encoder and transmitted via RF through transmitting antenna.

- Receiving module receives the message and passes it to the microcontroller.

- Microcontroller starts processing the program implemented on it.

- This leads the motor drive to provide high signal current to the motors which drives the conveyor belt and mechanical hand motors.

- If there is a metal/object detected on the receiver side of the conveyer belt using metal/IR sensor.

- The conveyor belt stops and the robotic arm performs its action depending upon the programming implemented on the microcontroller i.e. picks up the object and puts it at a required place as per the coding implemented in the ATMEGA16 microcontroller.

SUMMARY:

2.11) This project was to give the ways for providing bigger effective mechanical hand for industrial applications. The achievement of this hand is to demonstrate that reliable grasping can be achieved with inexpensive mechanism and IR sensors. This hand can grasp variety of objects with different surface properties and sizes, having no need to rebuild a surface description of the object. Overall, the journey of the project was very productive, learnt new skills and enhanced acquired skills. We submitted our project with final documentation and a presentation with the prototype to our head of department and tutor. Although we faced many difficulties during this project but we never gave up. The toughest part was to build the mechanical hand and time constraint but working with a team made this project successful.