Chloride Permeability Performance: Aggregate Concrete

|

FIGURES |

|

|

FIG.1 |

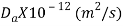

Relationship between replacement ratio of fine NA by fine RCA and chloride migration coefficient (Evangelista and de Brito 2010) |

|

FIG.2 |

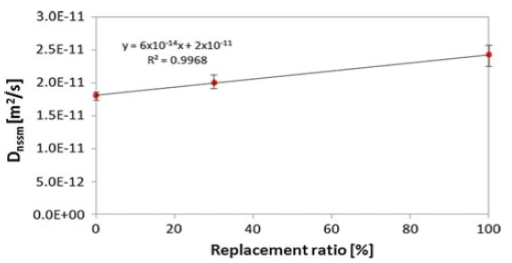

Chloride ion resistivity of RCAC (DR Concrete with RCA as fine and coarse aggregate; DN Concrete with coarse RCA and fine NA) (Tu et al.2006). |

|

FIG.3 |

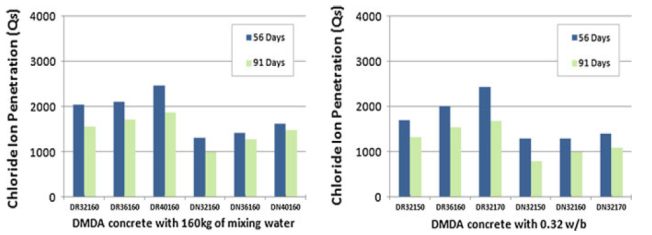

Effect of the mixing method on the resistance to chloride penetration of conventional concrete and RCAC (Kong et al. 2010) |

ABSTRACT

With the increasing concern about the environment and to build more sustainable and economical buildings, a great amount of researches are being done on the use of recycled aggregate (construction demolished aggregates) as a replacement of natural aggregates in concrete. As the concrete production becomes economical several properties are affected using RA. Major research have been done on both the mechanical and physical properties of RAC. Variation of result trend between the studies of different researchers have been seen throughout the years related to chloride permeability of RAC. The major reason behind the variation in chloride permeability of RAC is the residual mortar content of the recycled aggregates. The effect of different residual mortar content on chloride permeability is simulated and modelling is done in the research paper.

- INTRODUCTION

Concrete is the most used artificial construction material in the world since its invention. Over the world, three tons of concrete is used per year per person approximately. It is almost double the amount of all other construction materials used over the world. The massive use of concrete as construction material is due to availability of raw materials and its significant properties such strength, durability etc. Concrete comprises three major fractions of engineering materials, aggregate: binder and water. The aggregate proportion in concrete is about 3/4 of its total volume and therefore significantly effects in the overall performance of concrete.

Continuous development of the society in construction poses serious problem of disposal of construction and demolition waste. Environmental effects such as rapid change in climate and associated with global warming, depletion of natural resources and biodiversity water, air and soil pollutions, generation of large amounts of waste materials and their disposal which are major challenges suffered by present-day civilization. The release of emissions in large amounts of particulate materials and noxious gases including CO2, the major greenhouse gas, into the atmosphere, due to rapid industrialization and population civilization, is a major environmental concern and exigent measure is necessary to minimize it. Each of these issues generate serious concern to the future development of mankind if they are not tackled urgently. The evaluation of the impact of the current developments on the environment is therefore an important concern for present-day researchers and several initiatives have already been taken to reduce the problems related to these issues. Thus the term ”sustainable development” was invented, which proposes a developing society, where people focus living in a healthy environmental surrounding with improved economic and social conditions.

Recycling and reuse of waste materials is one of main objectives of sustainable development in modern society. Moving towards engineering aspects, a great extent of methodologies have been developed and still researchers see wide scope in utility of recycled materials in various engineering disciplines. some important recent development works in the field of cement and concrete technology is the use of various types of recycled waste materials as a raw material in cement production, as well as in the manufacturing of various types of concrete. Concrete production can consume a substantial amount of the total generated waste materials, which helps to the acute environmental impact of these materials and also leading to the much needed sustainability in concrete and cement production. The use of recycled waste materials as aggregate in concrete manufacturing consumes large amounts of them taking into account the scale of concrete manufacturing all over the world as well as the percentage of aggregate in the overall. Researchers presented a wide range of work in development of various types concrete by using waste and recycled materials which have adverse effect on environment. Research by concrete engineers has clearly suggested the possibility of appropriately treating and reusing such waste as aggregate in new concrete, especially in lower level applications such as road barriers, drainage structures etc. Use of these recycled materials helps to improve environmental deterioration effects as these have adverse effect on the surroundings where they are dumped. Also, large amount of Co2 is consumed by using these waste recycled aggregates. Major developed countries such US, JAPAN, UK, GERMANY, BULGARIA, HONGKONG used recycled aggregates concrete at large scale in past years.

Recycled Aggregates concrete is the concrete produced from the waste concrete aggregates which are obtained from demolished structures. Recycled concrete aggregates are divided into two categories. Some RCA aggregates comprises of natural aggregates with adhered mortar. These are produced from demolishing and recycling of precast concrete structures. On the other hand, in some RCA aggregates contains few adulterated materials such as bitumen particles, plastics, bricks and tiles are present in minor amounts along with natural aggregate and adhered mortar. The amount of extracted aggregates is 60-70% coarse and 30-35 % fine aggregates respectively from the recycled concrete blocks. These are obtained by simple processes; the demolished materials are separated from other building materials such reinforced steel bars. After separation the size of concrete blocks is reduced which are then graded through sieve. Finally, the aggregates are cleaned through process of water or air cleaning which can be used for various applications in concrete.

Since 1940’s a lot research and work has be done on recycle aggregates and concrete produced by using these aggregates, innovation of new mix designs the and improving properties of the recycle aggregates concrete but one of most concerned issue is the presence of attached mortar with the aggregates which totally alters the properties aggregates as well as the concrete manufactured using these as compared to natural aggregates and the conventional concrete. Almost each and every property related to aggregates and concrete is affected by the presence of mortar. Compressive, tensile or flexural strength, durability parameters or any fresh state properties have concrete shows an opposite trend as natural aggregates or conventional concrete. According to past research the recycled aggregates concrete has low compressive, flexural and tensile strength, more water absorption permeability, creep, shrinkage than conventional concrete due to presence of the residual mortar but it is more workable as w/c ratio has to be kept high. However, curing age shows significant improvement in the durability properties such as permeability. Analyzing the recycled aggregates concrete with various admixtures and supplementary cementitious materials show great results, altering the drawbacks in the recycled aggregates concrete increasing the utility of such type of concrete. Some Rilem recommendations have changed the phase of the recycled concrete to a large extent. When designing, a concrete mix using recycled aggregate of variable quality, a higher standard deviation should be employed in order to determine a target mean strength based on a required characteristic strength. When coarse recycled aggregate is used with natural sand, it may be assumed at the design stage, that the free w/c ratio required for a certain compressive strength will be the same for RAC as for conventional concrete. For a recycled aggregate mix to achieve the same slump, the free water content will be approximately 5% more than for conventional concrete. The sand-to-aggregate ratio for RAC is the same as when using NA. Trial mixes are mandatory and appropriate adjustments depending upon the source and properties of the RA should be made to obtain the required workability, suitable w/c ratio, and required strength of RAC.

- LITERATURE REVIEW

Different researches are purposely reviewed and used to support the research problem. In various researches, the incorporation of construction demolished waste (CDW) increased the chloride permeability whereas peers showed the less influence of construction demolished waste (CDW) on chloride permeability. Some of them also showed the effect of corrosion on the concrete performance due to chloride conductivity. The following section shows the information gathered during the literature review.

Olorunsogo and Padayachee (2002) replaced the Natural aggregate (NA) by recycled concrete aggregate (RCA) and they found the significant increase of chloride conductivity by 86.5% as when coarse aggregate was replaced. They also observed that with increase in curing time, the chloride conductivity decreases. Poon et al. (2006) observed the chloride penetration depends upon the method of curing whether it is steam cured or water cured, the former method has very less conduction of chloride in RAC. Gonçalves et al. (2004) found the lower chloride ion penetration when replaced the NA by RCA and used high cement content. They showed that the chloride conductivity is more influenced by paste quality rather than porosity of aggregates. Evangelista and de Brito (2010) also observed that by replacing NA to RCA there is increase in concrete porosity which results in the increase in chloride migration coefficient. The results are shown in Fig.1. Kou and Poon (2009a) also observed the lower chloride conductivity when replaced the fine natural aggregates by fine recycled concrete aggregates at constant water cement ratio which might be due to poor microstructure formation because of adhered mortar content on RCA whereas at constant slump, the results were quite similar to conventional concrete and recycled aggregate concrete (RAC). Rao et al. (2011) observed that at 100 % replacement of coarse NA by coarse RCA, the increase in chloride penetration depth was 14 % as compared to that of conventional concrete which was due to the presence of old porous mortar. The marginal difference was observed by Limbachiya et al. (2012) when they replaced 30% of NA by RCA but results was significant when they replaced it by 50% to 100%. The improvement was also observed in chloride conductivity when there was 30% incorporation of fly ash (SCM) replaced with OPC.

Fig.1. Relationship between replacement ratio of fine NA by fine RCA and chloride migration coefficient (Evangelista and de Brito 2010)

Tu et al. (2006) observed higher chloride penetration (CP) for high-performance concrete (hpc) with RCA as replacement of both fine and coarse NA than that observed for hpc with RCA as the only coarse aggregate and NA as the only fine aggregate due to the lowering of residual mortar content. The results are as shown in Fig.2.

Fig.2. Chloride ion resistivity of RCAC (DR Concrete with RCA as fine and coarse aggregate; DN Concrete with coarse RCA and fine NA) (Tu et al.2006).

Beside the replacement of percentage of NA by RCA, there are various studies done on the chloride permeability by looking at the effect of various factors such as curing age, water cement ratio, mineral admixtures. Kou et al. (2011b) observed a significant improvement of chloride permeability resistance in conventional concrete as well as in RCAC due to the replacement of 10, 15, 35 or 55 % of OPC by SF, MK, FA or ground granulated blast furnace slag (ggbfs), respectively and the ranking of improvement was: ggbfs>FA>MK>SF. The results were calculated for concrete specimen after 28 and 90 days. Kong et al. (2010) observed comparable resistances to chloride ion penetrations of concrete with RCA as the only coarse aggregate and conventional concrete when coarse RCA was pre-coated with FA or slag before mixing. They applied three mixing methods to prepare concrete: normal mixing (NM); double mixing (DM), which is described in Sect. 5.2.1. (for details, see Tam and Tam 2008); triple mixing (TM) in which fine and coarse aggregates were initially mixed for 15 s with part of the mixing water, then the mineral addition was added and mixed for another 15 s to coat the surface of aggregate, after this cement was added and mixed for another 30 s; finally, the remaining water along with the superplasticizer were added. The results are as shown in fig.3.

Fig.3. Effect of the mixing method on the resistance to chloride penetration of conventional concrete and RCAC (Kong et al. 2010)

In case of modelling and simulation, Xiao et al. (2012c) proposed a model on the chloride penetration in RAC due to recycled aggregate and theoretical equations to calculate the effective chloride diffusivity. Xiao et al. (2012b) showed that the modeled RAC does not contain chloride concentration in uniform pattern and it decreases with the diffusion path during simulation.

The increase in RCA content in the concrete also increases the chloride permeability resulting in effecting the durability of the concrete. A.Abbas et al. (2009) showed that the increase in mortar content results into increase in various durability factors such as freeze-thaw, chloride penetration, and carbonation. They used the equivalent mortar method to proportion the RCA-concrete and conducted different tests to study the effect of the durability. By this method, the lower mortar content in RCA-concrete can be achieved which shows greater resistance against the chloride permeability. Jingwei Ying (2013) proposed five phase composite sphere model for the RCA-concrete and found that chloride diffusivity of RCA-concrete increase with increase in old residual mortar.

- SCOPE

Using CDW as an aggregate in the preparation of new concrete has immense potential and it has been the object of investigation for a long time. The scope of the study is to evaluate various research papers on chloride permeability of Recycled Aggregate Concrete (RAC). The objective is also to looks at the effect on chloride permeability when natural aggregates (NA) are replaced with recycled aggregate in a concrete mix. A lot of researches have been done but the results and conclusions vary from one research to other as the researchers talk about the chloride permeation and corrosion caused by chloride action on steel in reinforced concrete containing RCA. Some researchers say that a significant increase in chloride permeability can be seen, on the contrary some say that negligible increase is observed.

The major reason behind the variation in chloride permeability of RAC is the residual mortar content of the recycled aggregates. Most of the researchers do not consider the percentage of mortar adhered to the aggregates while performing their calculations. But RMC being the significant reason for the variation in chloride permeability due to its porous nature and less strength, there is a need to look into its effect. Simulation and modelling will also be done by taking different % of RMC content and its effect on the chloride ingress in comparison to the permeability of natural aggregate concrete.

A significant variation in the properties can be observed when along with RCA, supplementary cementitious materials (SCM) are used in concrete. SCM’s along with RCA not only lower the cost of production of concrete but also can provide durability properties better than that of conventional concrete. In this term paper the focus will also be on the effect of SCM’S in RAC on the chloride-ion permeability, does it increase or decrease? And what factors cause this variation. Chloride permeability also depends on several factors in case of RAC, namely curing methods used i.e. steam curing or regular water curing, the curing time of RAC. The interlocking of particles in RAC also effect the permeability which will also be discussed in the paper.

Most of the researchers have given contradicting statements related to the effect of RCA on chloride ion permeation of RAC, to bridge the gap between the studies modelling and simulation will be done to provide a much clearer and in-depth knowledge about this concept.

- EXPERIMENTAL PROGRAM

- Material characterization of RCA

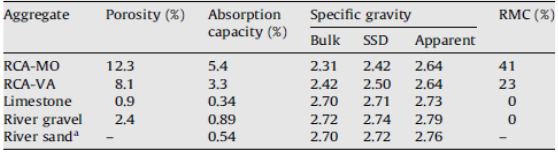

The material was received from different demolished project sites and it is mixture of different aggregates sizes from different sources. The two batches were selected from different locations. The first batch was obtained from the recycled aggregate processing batch located in Montreal, Québec (RCA-MO) and the second batch was from plant located in Vancouver, British Columbia (RCA-VA). Both materials had different aggregate specifications as the former material was obtained from concrete made up of crushed limestone and the later material was obtained from demolished concrete made up of well-rounded river gravel. Before starting the material characterization testing, these materials are screened and passed through the sieves of different sizes such as 4.75, 9.5, 12.7, 19, and 25 mm. Even the time was fixed to avoid the damage to RCA.

When petrographic examination was performed, it showed RCA-MO aggregates consisted of crushed fine-grained, dark-grey limestone whereas RCA-VA consisted of well-rounded polygenic gravel. The particle size distribution of both Materials were within the range of 5-25 mm. To check the micro-textural and compositional characteristic of residual mortar, the materials were examined under the scanning electron microscope (SEM). This could help in determining the performance of the RCA. It showed that the RCA-MO was more porous than the RCA-VA. The residual mortar in RCA-VA also contained the fly ash which was classified as CSA type CI and calcium oxide content of approximately 10-15%.

The material characteristics such as absorption capacity, specific gravity, porosity and residual mortar content was determined for both the materials and also for the natural aggregates which is shown in table 1.

Table 1. Average physical properties for coarse and fine aggregates (A. Abbas et al. 2009)

From table, the RCA-MO had more porosity and the absorption capacity which is dependent upon the presence of percentage of the residual mortar content in RCA.

- Methods to determine chloride permeability

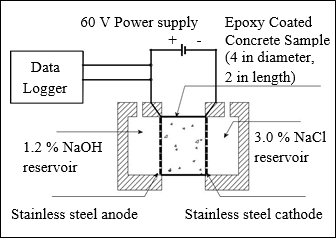

- Rapid chloride permeability test

Standardized testing procedures are in AASHTO T 277 or ASTM C 1202. The RCPT is performed by monitoring the amount of electrical current that passes through a sample 50 mm thick by 100 mm in diameter in 6 hours. This sample is typically cut as a slice of a core or cylinder. A voltage of 60V DC is maintained across the ends of the sample throughout the test. One lead is immersed in a 3.0% salt (NaCl) solution and the other in a 0.3 M sodium hydroxide (NaOH) solution. Based on the charge that passes through the sample, a qualitative rating is made of the concrete’s permeability. By knowing the current and time history, the total charge

(coulombs) passed through the specimen was computed by Simpson’s integration. Versatile and easy to conduct, the RCPT has been adopted as a standard and is now widely used.

Fig. 4 RCP TEST SETUP

The test, however, has a number of drawbacks: The current that passes through the sample during the test indicates the movement of all ions in the pore solution (that is, the sample’s electrical conductivity), not just chloride ions. Therefore, supplementary cementitious materials (such as fly ash, silica fume, or ground granulated blast-furnace slag) or chemical admixtures (such as water reducers, super-plasticizers, or corrosion inhibitors can create misleading results largely due to the chemical composition of the pore solution, rather than from the actual permeability. As a result, some researchers do not recommend the RCPT to evaluate the chloride permeability of concrete containing these materials.

The conditions under which the measurements are taken may cause physical and chemical changes in the specimen, resulting in unrealistic values. For example, the high voltage applied during the test increases the temperature of the sample, which can accelerate hydration, particularly in younger concretes. The test has low inherent repeatability and reproducibility characteristics. The precision statement in ASTM C1202-97 indicates that a single operator will have a coefficient of variation of 12.3%; thus, the results from two properly conducted tests on the same material by the same operator could vary by as much as 42%. The multi-laboratory coefficient of variation has been found to be 18.0%; thus, two properly conducted tests on the same material by different laboratories could vary by as much as 51%. For this reason, three tests are usually conducted and the test results averaged, which brings the multi-laboratory average down to 29%.

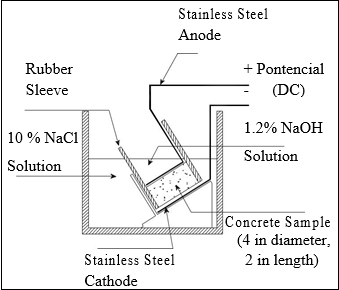

4.2.2 Rapid Migration Test

Rapid Migration Test is introduced as a promising alternative to commonly used Rapid Chloride. Luping Tang and Lars-Olof Nilsson proposed the at Chalmers Technical University in Sweden. Some of the researchers consider it as a reliable and precise method. The test procedure can be carried out with a similar apparatus as is used to conduct the Rapid Chloride Permeability Test.

In this test a saturated sample of dimensions 4-inch diameter and 2-inch length is used and current is passed through the sample so that the chloride ions move into the specimen (NT BUILD 492 1999). To check the fluctuating resistance to the current flow by concrete, the initial flow is measured and the voltage is modified accordingly. The specimen is fit into the rubber sleeves made of silicon in such a way that one of the side of the sample is submerged in 0.3 N NaOh solution and the other side is exposed to 10% NaCl solution. The current is then passed through the sample for specified time depending on the type of the sample, in some cases it is 8 hours which could even go up to 4 days. After this time the sample is removed and cut into two pieces and with the help of a colorimeter technique (spraying silver nitrate solution on the freshly cut sample) the chloride penetration is determined.

FIG. 5. RAPID MIGRATION TEST SETUP

Originally it was proposed that the sample should be exposed to current for 8 hours after which the splitting and testing of the specimen can be done. The time period was then changed by Tang and Nilsson to 4 days by using varying voltages and test durations and was named Nordtest procedure. As this procedure still had some problems a protocol was developed evaluating different voltages and time durations (Hooton, Thomas and Stanish 2001), the duration was set to 18 hours.

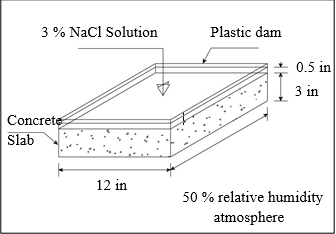

4.2.3 90-Day Salt Ponding Test (Aashto T259)

AASHTO T259 is widely used to determine the chloride penetration in concrete. In this test three concrete slabs of dimension 12in x12in x3in are casted and cured for 14 days. These slabs are then dried in a room with 50% humid environment for 28 days. On the slab 0.5inch high blockage is made to hold 3% NaCl solution the rest of the area of the slab is exposed to drying conditions. The sample is kept like this for 90 days after which the sample is removed from the drying room and the chloride content is determined in 0.5in thick slice of the slab.

Fig.6. 90 DAY PONDING TEST

The chloride analysis is done at an approximate incremental depth of 0.5inch of the sample which is drilled through the slab. Using either AASHTO T 260 or ASTM C1152 the samples are analysed for total acid-soluble chloride. Sampling at 0.5-in. (13-mm) depth increments provides an average indication of chloride ingress into the concrete. The chloride content is measured at different depths. But it is difficult to analyse what the results mean. As only one face of the slab is exposed to chloride ions and the average chloride ion concentration is calculated of the 0.5 in and not the actual variation throughout the 0.5-in slice. Measuring of actual variation rather than average variation provides more detailed information regarding the chloride ingress. Another limitation of this test is that the test takes approximately 118 days to complete which is a lot of time if we consider the practicality of the test as the concrete testing needs to start 3-4 months before the actual application of the concrete. In some types of concrete having SCM’s the 90-day period to check chloride ingress is not sufficient as they provide higher resistance to permeability.

The ponding test is controversial as some of the researcher’s state that, as only one face is submerged it increases the chloride ingress as compared to the natural diffusion of chloride ions in concrete. The chloride absorption will be more in concrete during the test as compared to the diffusion of chloride during the lifetime of the structure.

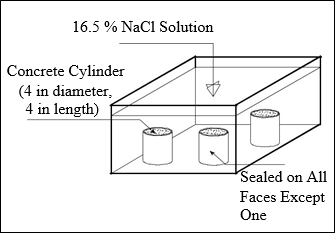

4.2.4 Bulk Diffusion Test

To overcome the flaws in the salt ponding test bulk diffusion test was developed to calculate the diffusion of chloride ions. In this test the samples configuration is 4 inch diameter by 4 inch high cylinders and ponding is done on one of the face while all the other faces are coated and prevented from air instead of preventing just the sides from air as in salt ponding test. Another difference is that instead of drying the sample for 28 days as in salt ponding test, the sample is saturated with limewater. Saturating with limewater hinders the initial sorption effect on the introduction of NaCl solution. This prevents any initial sorption effects when the chloride solution is introduced. The ponding is done with 2.8 M NaCl solution and left for 35 days after which the chloride penetration is determined [NordTest, NTBuild 443-94]. For lower-quality concretes the required exposure period is at least 35 days (NTBuild 443 1995) and for high quality concrete the exposure period is 90 days.

Fig.7. BULK DIFFUSION TEST SETUP

The chloride profile of the sample is established by fixing the sample to a mill or a lathe having diamond bit. The sample is then adjusted such that the surface of the sample is perpendicular to the tip of the bit. The sample is then drilled turning it into dust, this dust is then collected to evaluate the chloride penetration. The process is repeated at an incrementing depth of 0.5mm. The chloride content of the powder is then determined per AASHTO T260. Using the error function solution of Fick’s Second Law surface chloride concentration and diffusion value is determined. Even though Nordtest is capable of representing chloride diffusion into concrete, it is still a long-term test.

5. Method for determining residual mortar content

Equivalent mortar volume (EMV) method

The equivalent mortar volume method is used to determine the amount of recycled concrete aggregate to be used with respect to coarse natural aggregates in conventional concrete mix with keeping all the other properties same. The concrete produced with recycled concrete aggregate contain the residual mortar. So, the total volume of mortar is the volume of residual mortar and the added new mortar. For the conventional concrete the coarse aggregates are considered as recycled concrete aggregates whereas the residual mortar is not considered as part. In this case, concrete made up of RCA has larger volume of total mortar than the normal concrete produced with aggregates. The main aim of this method is to ensure that the volume of total mortar produced in concrete with RCA and conventional is same.

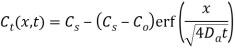

The first part of this method is to determine the proportions of materials used to produce conventional concrete mix by using mixture proportioning method. The required volume of RCA can be calculated with respect to the natural aggregate used by the following formula:

Where,  = Volume fraction of coarse RCA in RCA-concrete,

= Volume fraction of coarse RCA in RCA-concrete,

= Volume fraction of fresh aggregate in the conventional concrete,

= Volume fraction of fresh aggregate in the conventional concrete,

RMC = Residual mortar content of RCA,

= Specific gravity of RCA,

= Specific gravity of RCA,

= Specific gravity of natural aggregate,

= Specific gravity of natural aggregate,

R = Volume ratio of the natural aggregates of RCA concrete to the natural

aggregates of Conventional concrete.

After calculating the volume of RCA, the proportions of other materials are calculated. The different values of parameter R are assumed to get many RCA mixtures which can be designed.

6. Simulation

A.Abbas (2009) analysed the durability factors of various mix designs prepared with conventional mix design method and equivalent mortar volume method. Considering both methods, the chloride diffusivity coefficient is evaluated by taking various percentage values of residual mortar. Using the equations for chloride ion concentration, apparent diffusion coefficient is calculated and from EMV equation, the value of RMC is calculated. Two different RCA samples were used as reference for the calculations. Simulation is carried from the extracted equation and the results were plotted. The correlation was developed between the diffusion coefficient and the different SCMs (Fly ash, Blast furnace slag) used in mix design.

Steps used for simulation:

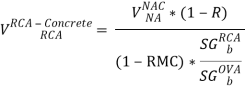

- Calculation of apparent diffusion coefficient (Da):

Where,  is total chloride ions concentration at the time (t) in seconds and

is total chloride ions concentration at the time (t) in seconds and

Depth (x) is in meters.

is chloride concentration on exposed surface.

is chloride concentration on exposed surface.

is the initial chloride concentration

is the initial chloride concentration

erf is the error function.4

Table.1. Results of acid soluble chloride content determination test. (A.Abbas et al. 2009)

|

Mix ID |

|

|

|

|

CM-C |

0.018 |

1.238 |

4.45 |

|

CV-C |

0.008 |

1.120 |

3.84 |

|

EM-C |

0.022 |

1.209 |

4.87 |

|

EV-C |

0.006 |

1.703 |

4.26 |

- Calculation of residual mortar content (RMC):

From equation (1)

Using equivalent mortar volume method, the residual mortar content of the two selected samples (RCA-Montreal, RCA-Vancouver) were calculated. For former sample has the value equals to 41% whereas the latter has the value of 23%.

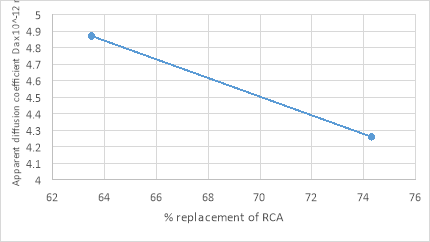

- Using MS-excel, the graph is plotted between the apparent chloride diffusion coefficient and residual mortar content.

As we can interpret from the graph that a linear equation was obtained between Da and RMC. The equation is given as:

Da = 0.0339 RMC + 3.4806

Now, considering the above equation as reference equation, the table given below was obtained by calculating different values of diffusion coefficient by assuming the different values of residual mortar content.

|

RMC |

|

|

0 |

3.4806 |

|

8 |

3.7518 |

|

13 |

3.9213 |

|

18 |

4.0908 |

|

23 |

4.2603 |

|

28 |

4.4298 |

|

33 |

4.5993 |

|

38 |

4.7688 |

The graph below was plotted from the above table by using MS-excel

From the graph, with increase in percentage of residual mortar content the chloride diffusivity increases gradually. The value of diffusion coefficient lies between 3.48 and 4.76 with increase value of residual mortar from 0 to 38%.

- Using different binders in the mixes namely Fly Ash, blast furnace slag a bar graph is plotted between diffusion coefficient and different SCM’s. This graph depicts the comparison between different mix design methods for recycled aggregates concrete namely conventional mix method and equivalent mortar volume method with different SCM’s.

It can be interpreted from the graph that the samples containing SCM’s designed using EMV method had lower value of diffusion coefficient as compared to the samples designed with conventional method. This trend is seen because of consideration of residual mortar content in EMV method. The values of diffusion coefficient in conventional mixes range from 3.83×10^-12 m^2/s to 1.95×10^-12m^2/s whereas in samples designed with equivalent mortar volume method the value of diffusion coefficient ranges from 2.56×10^-12m2/s to 1.8×10^-12m2/s.

- Taking into consideration the mix design derived from EMV method, the different percentage of RCA were replaced in the concrete mix. The graph is plotted between percentage of replacement of RCA and the diffusion coefficient. From graph, the value of diffusion coefficient decreases with increase in replacement of RCA because of the attached percentage of residual mortar is more in the Montreal sample than the Vancouver sample.

7. Discussion

Residual Mortar Content is a vital factor which needs to be considered while studying effect of recycled aggregates in concrete. More the value of chloride diffusion coefficient less is the durability of concrete. The chloride diffusion coefficient is dependent on the amount of residual content present in RCA. Therefore, the durability factor of RCA concrete can be increased by using the RCA of less residual mortar content. The alternative of achieving higher durability of RCA concrete is to prepare the mix design by replacing some amount of cement with SCM such as fly ash, blast furnace slag, metakaolin etc. Incorporation of SCM in concrete mix increases the durability properties of concrete by improving its permeability, workability and long term strength. The RMC governs over replacement ratio of RCA in chloride permeability even if the percentage of RCA increases. While designing the mix for RCA, RMC should be overviewed prior to the percentage of replacement of RCA.

8. Conclusion:

To come up with higher performance mix design of RCA, Residual mortar content should be taken into account along with other factors. In past researchers, have not worked on residual mortar content to explore different properties for RCA. The residual mortar content totally shows different image when considered for mix design of recycled aggregate concrete. To form more economical and environmental friendly concrete, Recycled aggregate along with SCM can be used. Nowadays, recycled concrete is used in barriers, retaining walls etc. but not in structural applications. Although, If in depth study is done on the mix design of RCA concrete by using EMV method incorporating various SCMs.

REFERANCES

- Gonçalves A, Esteves A, Vieira M (2004) Influence of recycled concrete aggregates on concrete durability

- Kong D, Lei T, Zheng J, Ma C, Jiang J, Jiang J (2010) Effect and mechanism of surface-coating pozzolanic materials around aggregate on properties and ITZ microstructure of recycled aggregate concrete. Constr Build Mater 24(5):701-708

- Kou S, Poon C (2006) Compressive strength, pore size distribution and chloride-ion penetration of recycled aggregate concrete incorporating Class-F fly ash. J Wuhan Univ Technol Mater Sci Edition 21(4):130-136

- Olorunsogo FT, Padayachee N (2002) Performance of recycled aggregate concrete monitored by durability indexes. Cem Concr Res 32(2):179-185

- Evangelista L, de Brito J (2010) Durability performance of concrete made with fine recycled Concrete Aggregates. Cem Concr Compos 32(1):9-14

- Kou S, Poon C (2009a) Properties of concrete prepared with crushed fine stone, furnace bottom ash and fine recycled aggregate as fine aggregates. Constr Build Mater 23(2):2877-2886

- Limbachiya M, Meddah MS, Ouchagour Y (2012) Use of recycled concrete aggregate in fly-ash concrete. Constr Build Mater 27(1):439-449

- Tu T-Y, Chen Y-Y, Hwang C-L (2006) Properties of HPC with recycled aggregates. Cem Concr Res 36(5):943-950